Organic waste gas adsorbent and preparation method thereof

An organic waste gas and adsorbent technology, applied in separation methods, chemical instruments and methods, gas treatment and other directions, can solve the problems of difficult promotion and use, high cost of matrix molecular sieves, and unfavorable recovery of organic waste gas, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

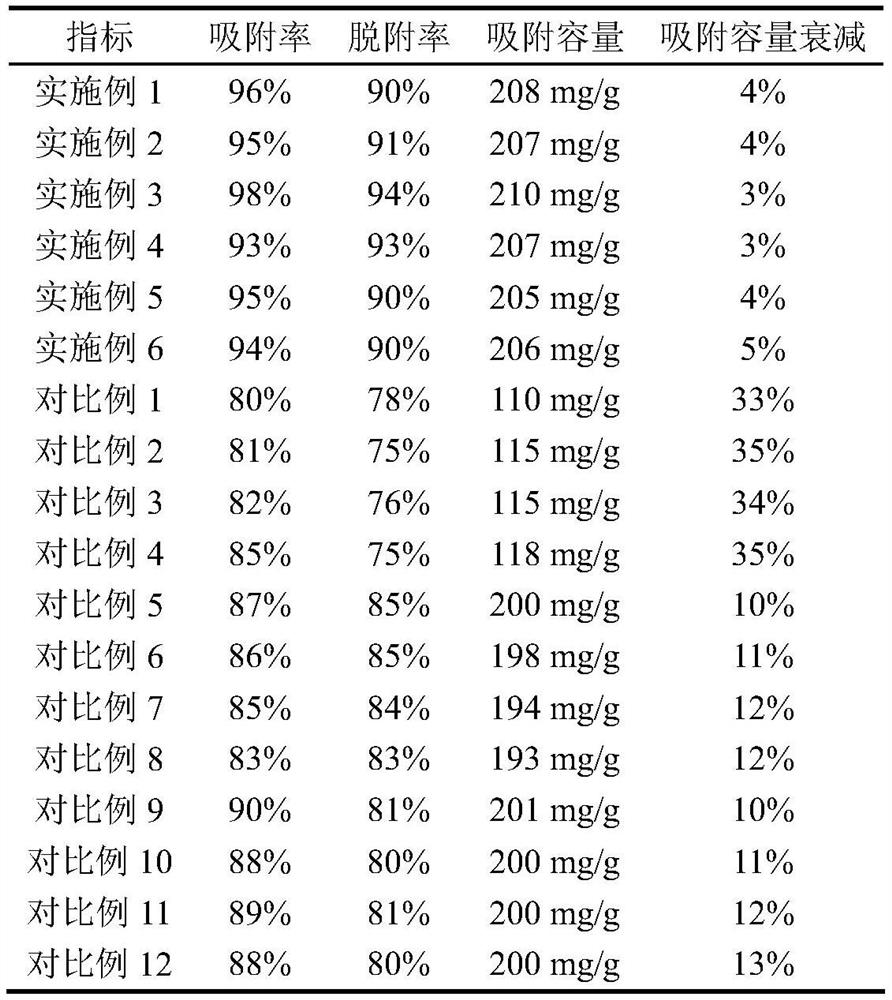

Embodiment 1

[0017] The invention provides an organic waste gas adsorbent, which comprises a carrier active semi-coke and a load of divinylbenzene, wherein the mass of the active semi-coke accounts for 90% of the total mass of the adsorbent, and the mass of divinylbenzene accounts for 90% of the total mass of the adsorbent. The percentage is 10%.

[0018] The method for preparing the organic waste gas adsorbent comprises the following steps:

[0019] S1. The raw material semi-coke and water are mixed in a mass ratio of 1:4, put into a high-pressure reactor for heating and activation for 2.5 hours, the pressure during heating is 6.5 MPa, and the temperature is 300 ° C. The method of heating and activation by steam can open the interior of the semi-coke. The pores are blocked, and the water vapor reacts with the carbon in the semi-coke to further expand the pores. In addition, the above-mentioned activation parameters, i.e. activation time, pressure and temperature, cooperate with each other...

Embodiment 2

[0024] The invention provides an organic waste gas adsorbent, which comprises a carrier active semi-coke and a load of divinylbenzene, wherein the mass of the active semi-coke accounts for 95% of the total mass of the adsorbent, and the mass of divinylbenzene accounts for 95% of the total mass of the adsorbent. The percentage is 5%.

[0025] The method for preparing the organic waste gas adsorbent comprises the following steps:

[0026] S1. The raw material semi-coke and water are mixed in a mass ratio of 1:4, put into a high-pressure reaction kettle for heating and activation for 3 hours, the pressure during heating is 7MPa, and the temperature is 280 °C. The pores, and the water vapor reacts with the carbon in the semi-coke to further expand the pores. In addition, the above-mentioned activation parameters, i.e. activation time, pressure, and temperature, cooperate with each other to control the collapse of 3-4% of the pore walls in the semi-coke pores to connect part of the...

Embodiment 3

[0031] The invention provides an organic waste gas adsorbent, which comprises a carrier active semi-coke and a load of divinylbenzene, wherein the mass of the active semi-coke accounts for 88% of the total mass of the adsorbent, and the mass of divinylbenzene accounts for 88% of the total mass of the adsorbent. The percentage is 12%.

[0032] The method for preparing the organic waste gas adsorbent comprises the following steps:

[0033] S1. The raw material semi-coke and water are mixed in a mass ratio of 1:4, put into a high-pressure reactor for heating and activation for 2.5 hours, the pressure during heating is 6.5 MPa, and the temperature is 300 ° C. The method of heating and activation by steam can open the interior of the semi-coke. The pores are blocked, and the water vapor reacts with the carbon in the semi-coke to further expand the pores. In addition, the above-mentioned activation parameters, i.e. activation time, pressure, and temperature, cooperate with each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com