Applications of ultrathin palladium sheets in promotion of carbon dioxide electroreduction

A carbon dioxide, ultra-thin technology, used in metal/metal oxide/metal hydroxide catalysts, electrodes, electrolysis processes, etc., can solve limited problems, achieve simple operation, reduce initial potential, and reduce overpotential effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

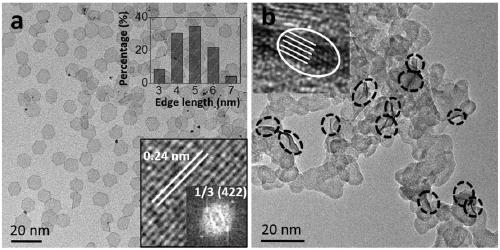

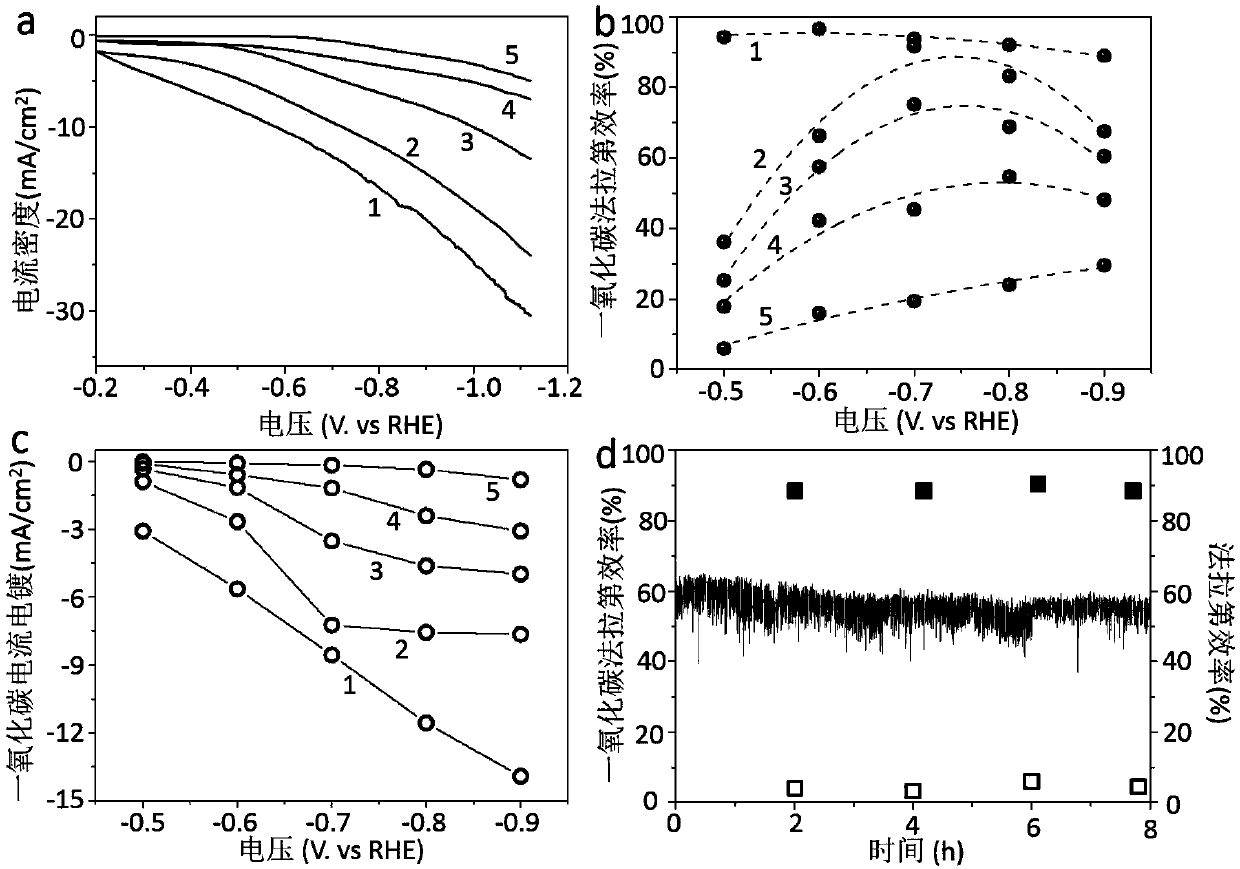

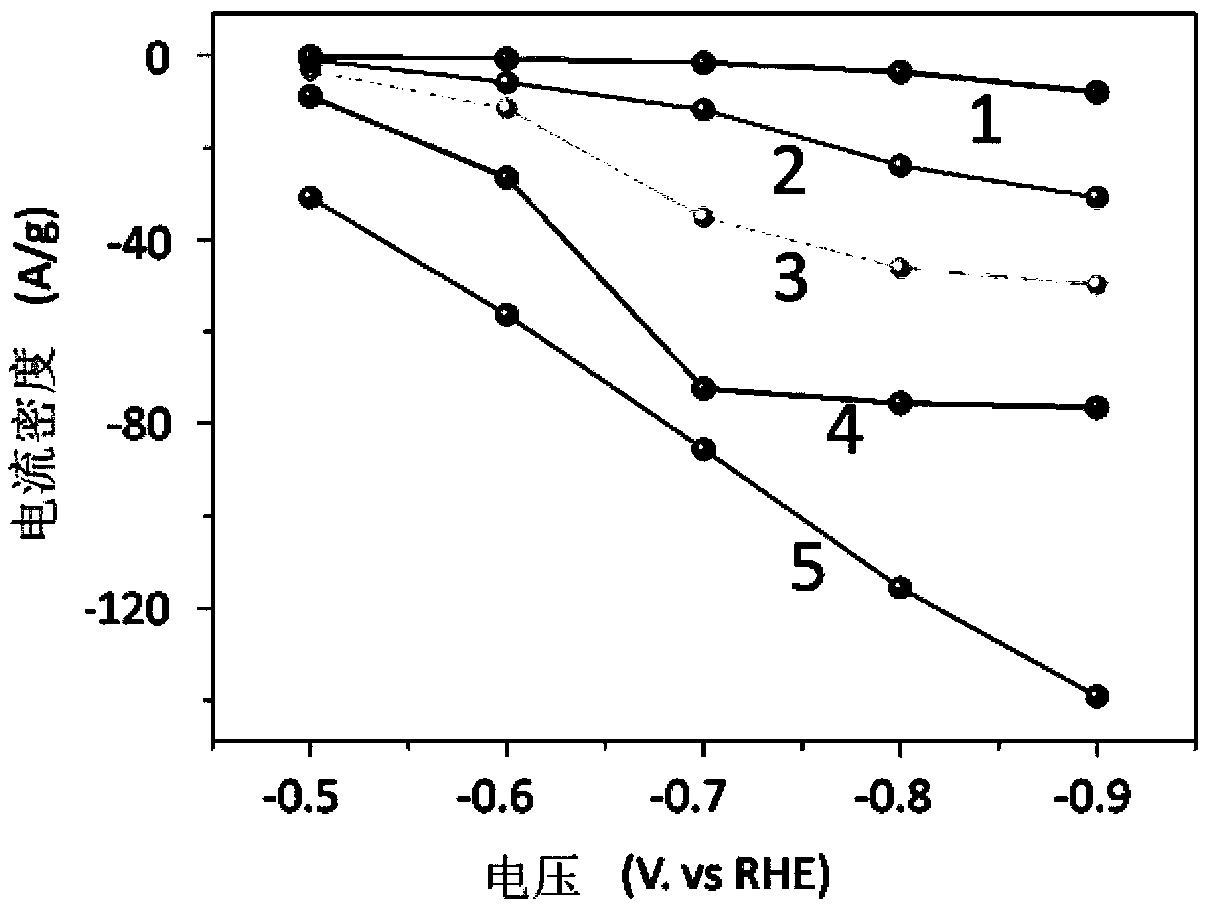

[0025] Example 1. Palladium acetylacetonate, polyvinylpyrrolidone, sodium bromide, N,N-dimethylformamide and water were mixed, refined for 10 hours, and the obtained homogeneous solution was transferred to a glass container. Introduce carbon monoxide to an atmospheric pressure, heat at 100 degrees Celsius, and cool to room temperature. The ethanol-acetone mixed solution was centrifuged to obtain palladium sheets (S.Tang, M.Chen, N.Zheng, Small 2014, 10, 3139-3144) with a side length of 5.1 nm, as follows:

[0026] (1) Mix 10 mg of palladium acetylacetonate, 32 mg of polyvinylpyrrolidone, 30.6 mg of sodium bromide with 2 mL of N,N-dimethylformamide and 4 mL of water, let stand for 10 hours, and transfer the resulting homogeneous solution to a glass container. Introduce carbon monoxide to atmospheric pressure, heat at 100°C for 1 hour, then cool to room temperature.

[0027] (2) Add 2 mL of acetone to the obtained product, and centrifuge at 10000 rpm for 10 minutes. The solid ...

Embodiment 2

[0030]Example 2. Palladium acetylacetonate, citric acid, hexadecylmethyltrimethylammonium bromide, polyvinylpyrrolidone, and N,N-dimethylformamide were mixed and allowed to stand for 1 hour. The resulting homogeneous solution was transferred to a flask, added tungsten hexacarbonyl, and reacted under an argon atmosphere. React at 80 degrees Celsius for half an hour. After cooling to room temperature, centrifuge to obtain palladium sheets with a side length of 9.6 nanometers (Y.Li, W.Wang, K.Xia, W.Zhang, Y.Jiang, Y.Zeng, H.Zhang, C.Jin, Z.Zhang , D.Yang, Small2015,11,4745-4752)—Adopt the method of Example 1 to react, the difference is only that the reaction reagent of step (1) is replaced by: 16mg palladium acetylacetonate, 140mg citric acid, 60mg hexadecyl Trimethylammonium bromide, 30mg polyvinylpyrrolidone, 100mg tungsten hexacarbonyl, 10mL N,N-dimethylformamide.

Embodiment 3

[0031] Example 3. Palladium acetylacetonate, citric acid, hexadecylmethyltrimethylammonium bromide, polyvinylpyrrolidone, and N,N-dimethylformamide were mixed and allowed to stand for 1 hour. The resulting homogeneous solution was transferred to a flask, added tungsten hexacarbonyl, and reacted under an argon atmosphere. React for one hour at 80°C. After cooling to room temperature, centrifuge to obtain palladium flakes with a side length of 15.9 nanometers (Y.Li, W.Wang, K.Xia, W.Zhang, Y.Jiang, Y.Zeng, H.Zhang, C.Jin, Z.Zhang , D.Yang, Small 2015,11,4745-4752)—Adopt the method of Example 1 to react, the difference is only that the reaction reagent of step (1) is replaced by: 16mg palladium acetylacetonate, 90mg citric acid, 60mg hexadecane Trimethylammonium bromide, 30mg polyvinylpyrrolidone, 100mg tungsten hexacarbonyl, 10mL N,N-dimethylformamide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com