Lightweight high-strength concrete and preparation method thereof

A high-strength, concrete technology, applied in the field of building materials, can solve problems such as broken, micro-cracks, and bulky, and achieve good strength and improved technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

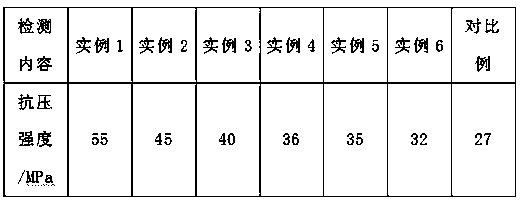

Examples

example 1

[0037] A lightweight high-strength concrete comprising the following raw materials in parts by weight: 100 parts of sea sand, 40 parts of cement, 20 parts of modified fly ash, 20 parts of modified sepiolite, 30 parts of water, and 5 parts of silane coupling Agent, 20 parts of polyethyleneimine aqueous solution, 20 parts of peach gum solution, 20 parts of modified fiber.

[0038] The cement is sulfate cement.

[0039] The silane coupling agent is silane coupling agent KH-550.

[0040] The preparation steps of described lightweight high-strength concrete are as follows:

[0041] (1) In terms of parts by weight, take 100 parts of fly ash and 50 parts of deionized water in turn, put the fly ash and deionized water in a high-pressure reactor, and then feed it into the reactor at a rate of 8mL / min Liquid nitrogen, until the pressure of the reactor reaches 2MPa, keep the pressure and ultrasonically treat for 20min, open the outlet valve of the reactor, spray the material into the c...

example 2

[0047] A kind of lightweight high-strength concrete, comprising the following raw materials in parts by weight: 100 parts of sea sand, 40 parts of cement, 20 parts of fly ash, 20 parts of modified sepiolite, 30 parts of water, 5 parts of silane coupling agent, 20 parts of polyethyleneimine aqueous solution, 20 parts of peach gum solution, 20 parts of modified fiber.

[0048] The cement is sulfate cement.

[0049] The silane coupling agent is silane coupling agent KH-550.

[0050] The preparation steps of described lightweight high-strength concrete are as follows:

[0051] (1) In parts by weight, take 20 parts of sepiolite, 100 parts of water, 3 parts of Bacillus pasteurianus, 5 parts of urea, and 5 parts of magnesium sulfate, mix the sepiolite with water, and add Bacillus pasteurianus Bacillus, urea and magnesium nitrate were placed in a mixing tank, and after stirring and mixing for 60 minutes at a rotating speed of 600r / min, a mixed slurry was obtained, and then the mixed...

example 3

[0056] A kind of lightweight high-strength concrete, comprising the following raw materials in parts by weight: 100 parts of sea sand, 40 parts of cement, 20 parts of modified fly ash, 20 parts of sepiolite, 30 parts of water, 5 parts of silane coupling agent, 20 parts of polyethyleneimine aqueous solution, 20 parts of peach gum solution, 20 parts of modified fiber.

[0057] The cement is sulfate cement.

[0058] The silane coupling agent is silane coupling agent KH-550.

[0059] The preparation steps of described lightweight high-strength concrete are as follows:

[0060] (1) In terms of parts by weight, take 100 parts of fly ash and 50 parts of deionized water in turn, put the fly ash and deionized water in a high-pressure reactor, and then feed it into the reactor at a rate of 8mL / min Liquid nitrogen, until the pressure of the reactor reaches 2MPa, keep the pressure and ultrasonically treat for 20min, open the outlet valve of the reactor, spray the material into the colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com