Method and device for on-line regeneration treatment of metal etching waste liquid

A waste liquid treatment and etching waste liquid technology, applied in the direction of electrolytic components, electrolysis process, etc., can solve the problems of low value of metal etching waste liquid, difficult electrolysis and regeneration process, high requirements for plate materials, etc., to achieve Effects of reduced addition, significant changes, and reduced etching costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for on-line regeneration treatment of metal etching waste liquid, which adopts membrane electrolysis technology, sucks a small amount of chlorine gas produced by electrolysis and catalysis through a water injector, and circulates and absorbs it, specifically including the following steps:

[0028] Step 1. Waste liquid treatment: After filtering the etching waste liquid produced by the metal etching production line through the electroplating filter, it is sent to the waste liquid treatment regeneration tank for electrolytic catalysis. The metal etching waste liquid mainly contains Fe 2+ and Fe 3+ , HCl, H 2 O, metal impurities and other components, waste liquid treatment regeneration tank adopts ionic membrane technology, and uses titanium alloy composite material electrode plate, according to the control index of the etching production line, according to the Fe in the etching waste liquid 2+ The amount, and by controlling the current density to control the gen...

Embodiment 2

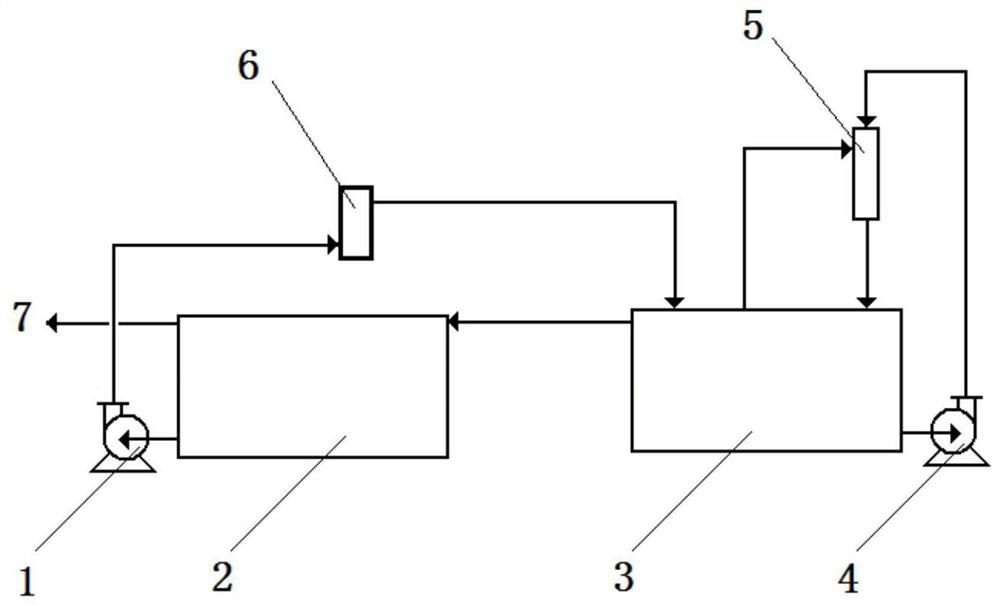

[0033] Such as figure 1 and figure 2 As shown, the device used in the method for on-line regeneration treatment of metal etching waste liquid in the present invention includes a metal etching production line 2 and a waste liquid treatment regeneration tank 3, and the lower outlet of the hardware etching production line 2 passes through a regeneration liquid delivery pump 1 and an electroplating filter 6 in sequence It is connected to the upper inlet of the waste liquid treatment regeneration tank 3, and the lower outlet of the waste liquid treatment regeneration tank 3 is connected to the upper entrance of the waste liquid treatment regeneration tank 3 through the waste liquid circulation pump 4 and the water ejector 5 in turn, and the waste liquid treatment regeneration tank The upper overflow port of 3 links to each other with the upper entrance of metal etching production line 2.

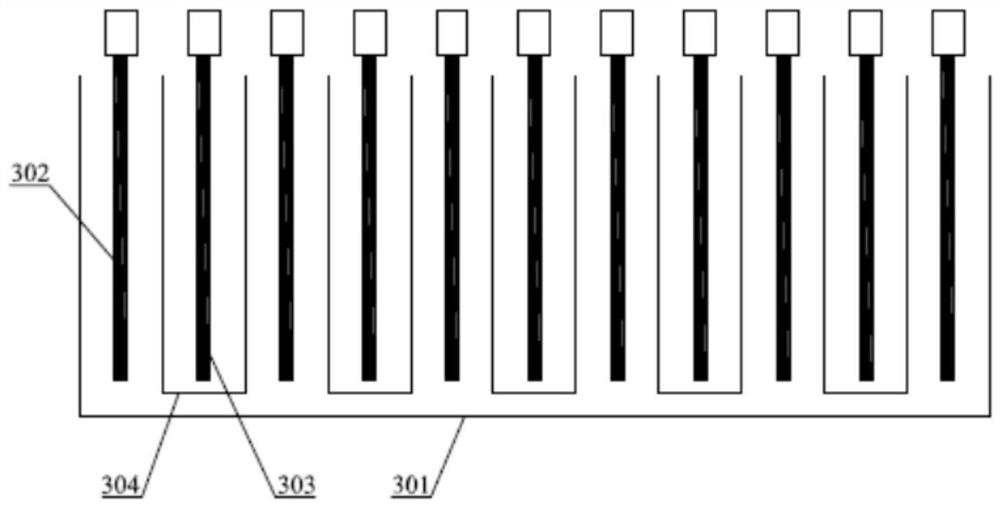

[0034] The waste liquid treatment regeneration tank 3 includes a tank body 301, and a plura...

Embodiment 3

[0037] In the operation of the metal etching production line, the acidity of the etching solution is controlled at 1.96mol / L; the specific gravity of the etching solution is controlled at 1.5, and the ORP value of the etching solution is controlled at 680mV; the etching waste liquid of the metal etching production line is sent to waste liquid treatment for regeneration Electrolytic catalysis is carried out in the tank, and the electrolytic current intelligent control method is adopted to control the current density of 10ASD, and a small amount of Cl produced 2 The amount is absorbed by the waste liquid circulation pump and water ejector, and the absorbed etching liquid overflows back to the metal etching production line for use.

[0038] The results after treatment are as follows: 62.8% emission reduction of metal etching waste liquid and 45% reduction in oxidant addition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com