Gas high-sealing low-loss pressurizing system and method

A supercharging system and high-sealing technology, which is applied in the direction of liquid variable displacement machinery, pump devices, machines/engines, etc., can solve the problems of gas compression and supercharging, reduce volume, reduce consumption, and reduce expensive gas consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

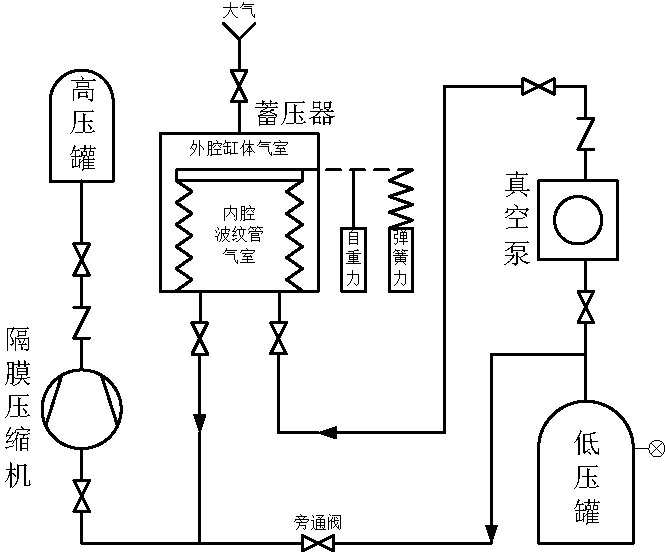

[0030] In order to perform dual functions of vacuuming and compression boosting for high-purity gases, expensive gases and dangerous gases, it reduces volume, reduces loss, and facilitates storage, transportation and process treatment. The invention provides a process flow diagram of a gas high-tightness and low-loss supercharging system, as shown in the accompanying drawings. The low-loss pressurization system of the present invention mainly includes at least one low-pressure tank, one vacuum pump, one pressure accumulator, one metal diaphragm compressor, one high-pressure tank, valves, pipelines and instruments, and the outlet of the low-pressure tank Connect to the inlet of the vacuum pump, the outlet of the vacuum pump to the inlet of the bellows air chamber in the accumulator inner chamber, the outlet of the bellows air chamber in the accumulator inner chamber to the inlet of the metal diaphragm compressor, the outlet of the diaphragm compressor to the high-pressure tank, ...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that when the low-pressure process gas in the low-pressure tank needs to be further compressed with a large compression ratio and pressurized into a high pressure (such as several or tens of MPa), the vacuum pump first The gas in the low-pressure tank is pumped into the pressure accumulator, and then the normal pressure or higher than normal pressure gas in the pressure accumulator is driven by gravity or spring force into the metal diaphragm compressor, and compressed and boosted to the high-pressure tank. At the end of compression, almost all the gas in the bellows chamber of the accumulator is sent to the diaphragm compressor for compression.

[0035] When it is necessary to pressurize the low-pressure gas in the low-pressure tank into high-pressure storage, if the gas pressure in the low-pressure tank is close to or lower than the normal pressure, the normal pressure in the low-pressure tank can be reduced by...

Embodiment 3

[0039] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that when the pressure of the process gas in the low-pressure tank is higher than the normal pressure, the process gas can be sucked out without a vacuum pump to vacuum the low-pressure tank. And the automatic pressure monitoring method, the pressure of the gas in the low-pressure tank can flow to the inlet of the diaphragm compressor to ensure the inlet pressure requirements of the diaphragm compressor.

[0040] A branch is connected in parallel at the outlet of the low-pressure tank, which directly bypasses the inlet of the diaphragm compressor, and a bypass valve is installed. A pressure sensor is installed on the low-pressure tank to monitor the pressure of the process gas in the low-pressure tank in real time. When the gas needs to be pressurized, if the gas in the low-pressure tank is higher than the normal pressure, the flow direction can be controlled by opening and closing the valve (aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com