Pneumatic axial flow type emergency cutoff valve

A technology of axial flow and cut-off valves, which is applied in the direction of sliding valves, balance valves, valve devices, etc., can solve the problems of weak flow capacity, low frequency, hindering gas flow and flow, etc., to reduce flow resistance and improve safety factor , the effect of preventing bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

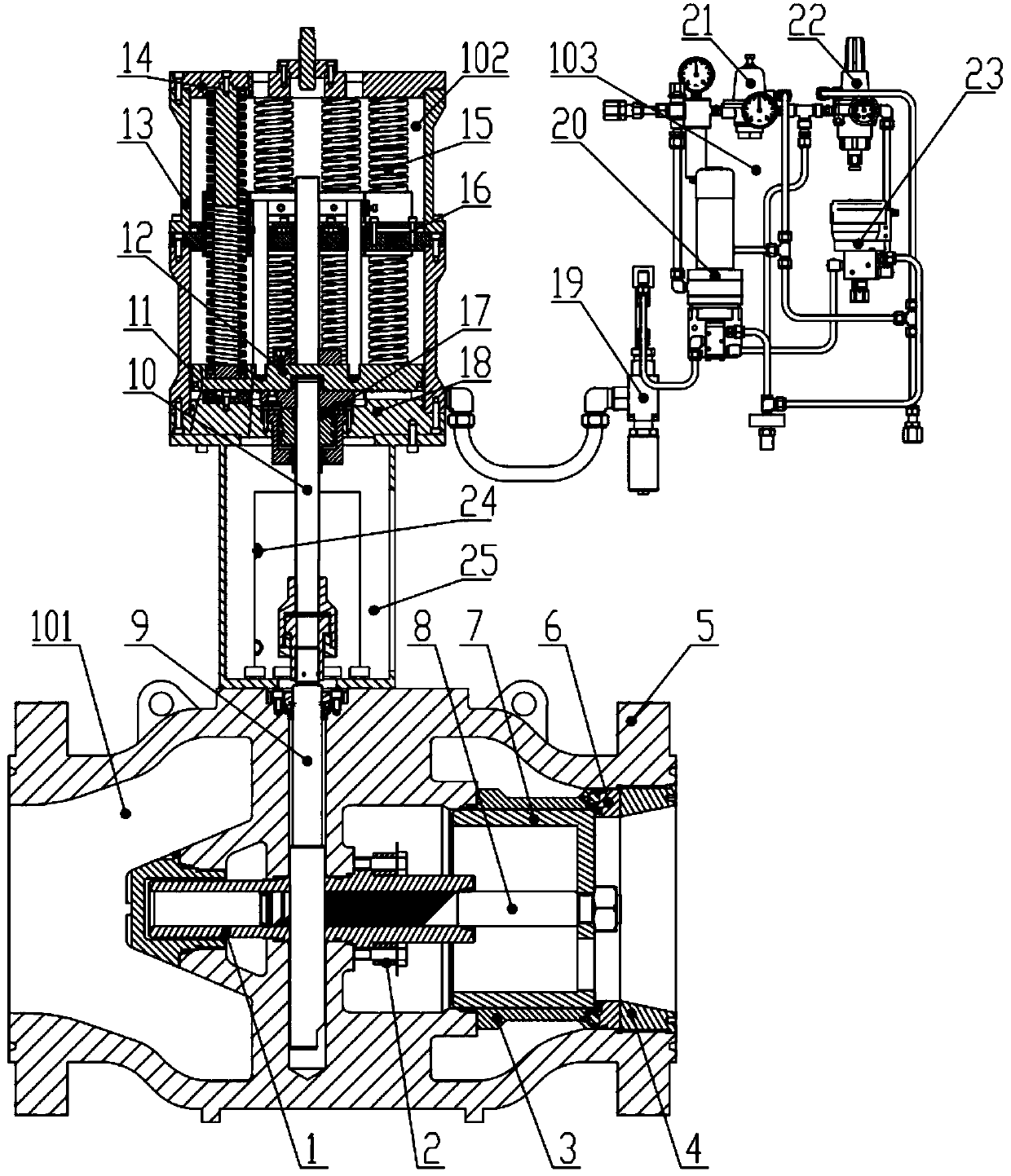

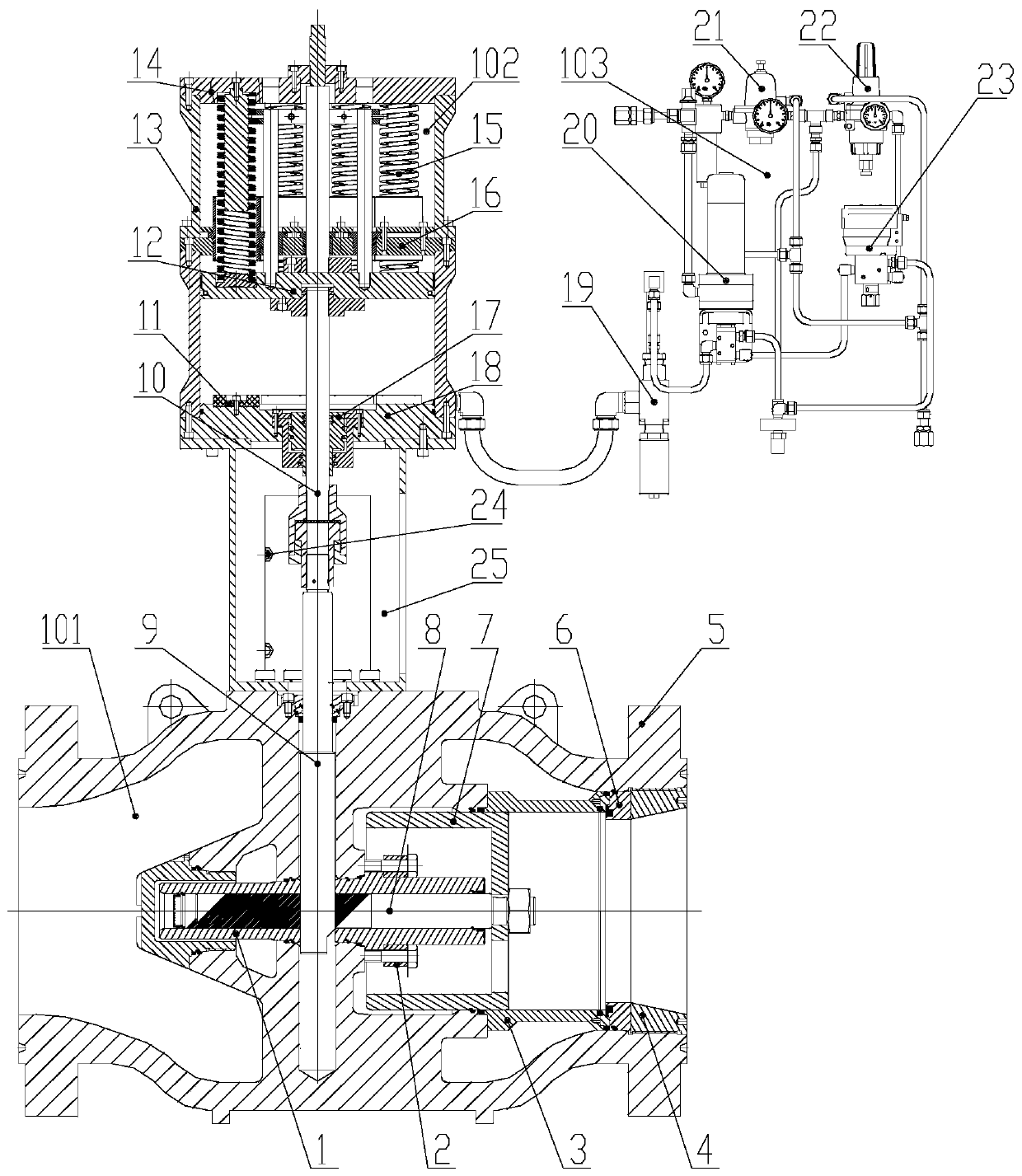

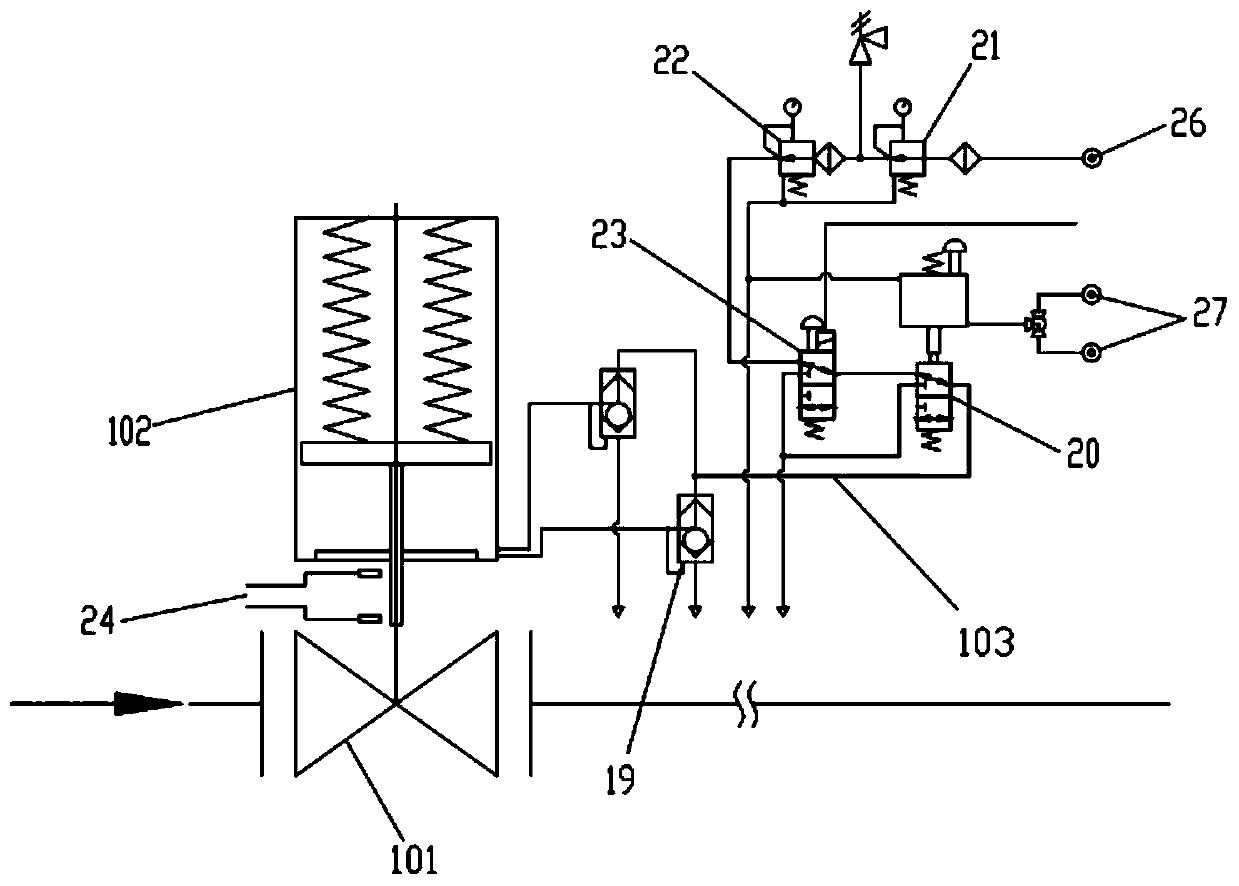

[0031]With reference to the accompanying drawings, a pneumatic axial flow emergency shut-off valve includes a guide sleeve 1, a gland 2, a support sleeve 3, a stop sleeve 4, a valve body 5, a sealing seat 6, a piston body 7, a piston rod 8, and a valve stem 9. Output shaft 10, buffer pad 11, piston 12, cylinder body 13, upper cylinder head 14, spring 15, guide plate 16, buffer device 17, lower cylinder head 18, quick discharge valve 19, pilot 20, pressure reducing valve 21. Filter decompression valve 22, electromagnetic valve 23. The guide sleeve 1 is fixed on the valve body 5 by the gland 2, the piston rod 8 passes through the piston body 7 and is fixed with a nut, the piston body 7 moves in the support sleeve 3 to control the valve switch, the support sleeve 3 and the seal The seat 6 is fixed on the valve body 5 through the connecting thread of the stop sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com