A novel tft device structure and manufacturing method thereof

A technology of device structure and manufacturing method, which is applied in the field of microelectronics, can solve the problems affecting the yield rate of the process, and achieve the effects of reducing the probability of light leakage, improving the brightness of the screen, and improving the yield rate of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

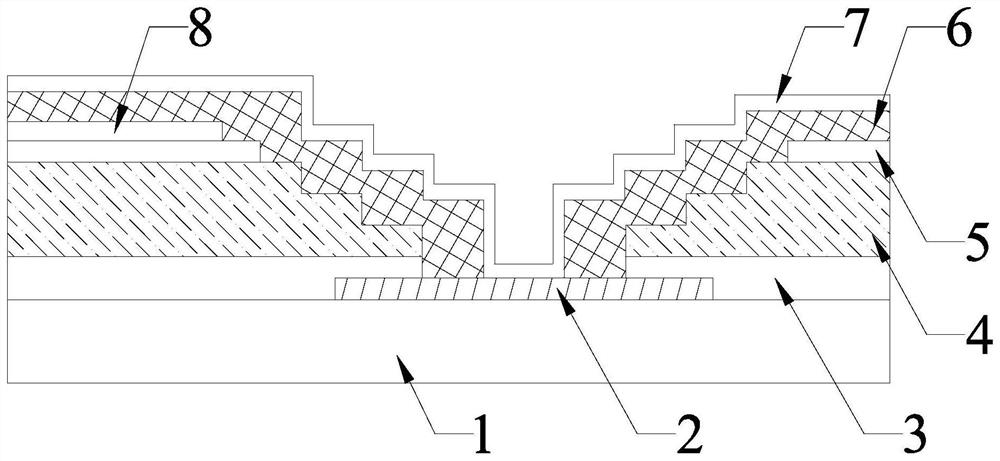

[0048] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0049] A new type of TFT device structure, including a substrate 1, on the surface of the substrate 1, a semiconductor layer 2, a first insulating layer 3, a flat layer 4, a second insulating layer 5, a third insulating layer 6 and a transparent conductive layer 7 are sequentially stacked , the vertical section of the flat layer 4 is stepped, and the order of the flat layer 4 is 2-5 layers, preferably 3 layers;

[0050] A via hole is opened on the first insulating layer 3, the via hole is set corresponding to the semiconductor layer 2, and the via hole is symmetrical to the axisymmetric center of the semiconductor layer 2, and the via hole is filled with the The third insulating layer 6 and the transparent conductive layer 7, the third insulating layer 6 is in contact with the semiconductor layer 2, the first insulating layer 3 and the flat layer 2 respectively, and the transparent conductive layer ...

Embodiment 2

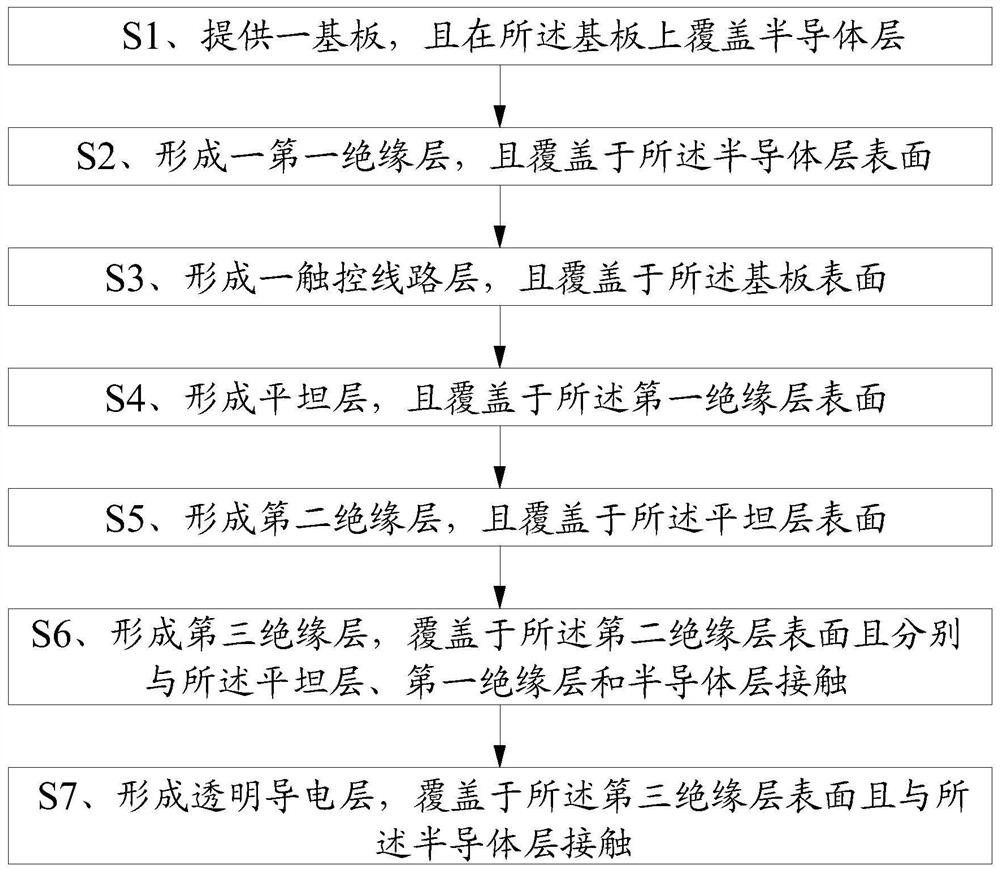

[0053] Please refer to figure 2 , the second embodiment of the present invention is:

[0054] A method for manufacturing a novel TFT device structure, comprising the following steps:

[0055] S1, providing a substrate 1, and covering the semiconductor layer 2 on the substrate 1;

[0056] S2, forming a first insulating layer 3, and covering the surface of the semiconductor layer 2;

[0057]S3, forming a via hole in the first insulating layer 3;

[0058] S4, forming a flat layer 4 and covering the surface of the first insulating layer 3;

[0059] Step S4 is specifically:

[0060] Place the photomask above the first insulating layer 3, and irradiate the upper surface of the photomask with ultraviolet light to form a stepped flat layer 4, and the flat layer 4 covers the surface of the first insulating layer 3;

[0061] The mask is a half-tone mask, and the number of steps of the flat layer 4 formed by using half-tone masks with different light transmittances is different, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com