Multilayer rice straw matrix block for machine-transplanted seedlings and seedling raising method

A technology of rice straw and matrix block, which is applied in the field of agricultural waste resource utilization, can solve the problems of cumbersome paving process of bulk straw matrix, low seedling rate of rice seeds, large consumption of manpower and material resources, etc., so as to reduce manpower paving. Process, excellent packing performance, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

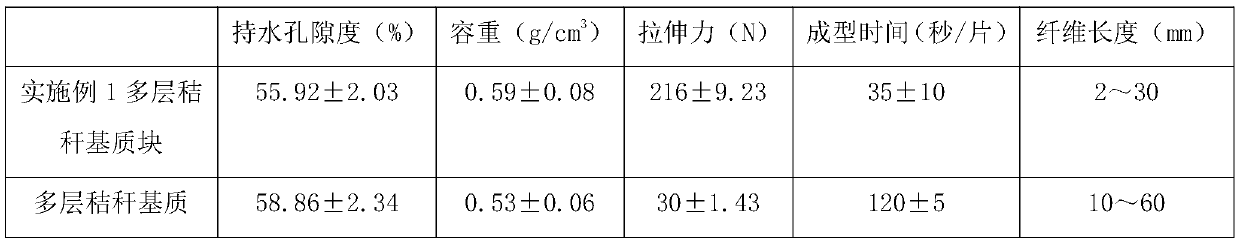

Embodiment 1

[0036] 1) adjust the moisture content of recovered crop straw (rice and wheat straw) to 25%, and prepare undecomposed straw fibers with an average length of 30 mm after the straw is kneaded and pulverized, and set aside;

[0037] Knead and pulverize straw fibers with an average length of 30mm and fully mix them with dung water with a concentration of 5%. Control at 55%; the fully mixed material is filled into a fermenter with a mechanical vent at the bottom for the fermentation process, and 15kg of cow dung water with a concentration of 1% is added every day, turned every 5 days, and part of it is taken out after 10 days of fermentation Straw fiber, that is, the straw fiber that has been decomposed for 10 days, is used for later use; after 10 days of fermentation, the color of the material becomes darker and slightly softened;

[0038] Continue to ferment the remaining straw fibers, turn the pile fully and evenly each time, add 8kg of dung water every day, keep the temperature...

Embodiment 2

[0065] Example 2 Preparation of multi-layer straw matrix block

[0066] 1) Adjust the moisture content of the recovered crop straw to 25%, and prepare undecomposed fiber straw with an average length of 15 mm after the straw is kneaded and pulverized, and set aside;

[0067] Fully stir and mix the kneaded and crushed undecomposed straw fiber with 1% manure water, add 150kg sheep manure water for every 75kg straw fiber, and control the moisture content of the selected cow manure water at 60%; the fully mixed material is loaded Enter the fermentation tank with a mechanical vent at the bottom for the fermentation process, add 15kg of sheep manure water with a concentration of 1% every day, turn the pile once every 5 days, and take out part of the straw fiber when it is fermented for 10 days, which is the straw fiber that has been decomposed for 10 days. Standby; the straw fiber material obtained by this fermentation becomes darker and slightly softened;

[0068] Continue to ferme...

Embodiment 3

[0078] Example 3 Preparation of multi-layer straw matrix block

[0079] 1) Adjust the moisture content of the recycled crop straw to 25%, and prepare fiber straw with an average length of 20 mm after the straw is kneaded and crushed, which is the unripe straw fiber, and is ready for use;

[0080] The kneaded and crushed undecomposed straw fiber is fully mixed with the manure water with a concentration of 3%, and 150kg of pig manure water is added to every 75kg of straw fiber, and the moisture content of the selected pig manure water is controlled at 75%; the fully mixed material is filled into The fermenter with a mechanical vent at the bottom is used for the fermentation process, and 15kg of pig manure water with a concentration of 1% is added every day, and the pile is turned every 5 days. After 10 days of fermentation, some straw fibers that have been decomposed for 10 days are taken out for use; the color of the material becomes darker. , with slight softening.

[0081] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com