Freeze-dried tomato beef noodle and preparation method thereof

A tomato and beef noodle technology, applied in the direction of food science, etc., can solve problems such as poor color, rough soup, cloudy soup, etc., to achieve the effect of maintaining color, neat appearance, and avoiding coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

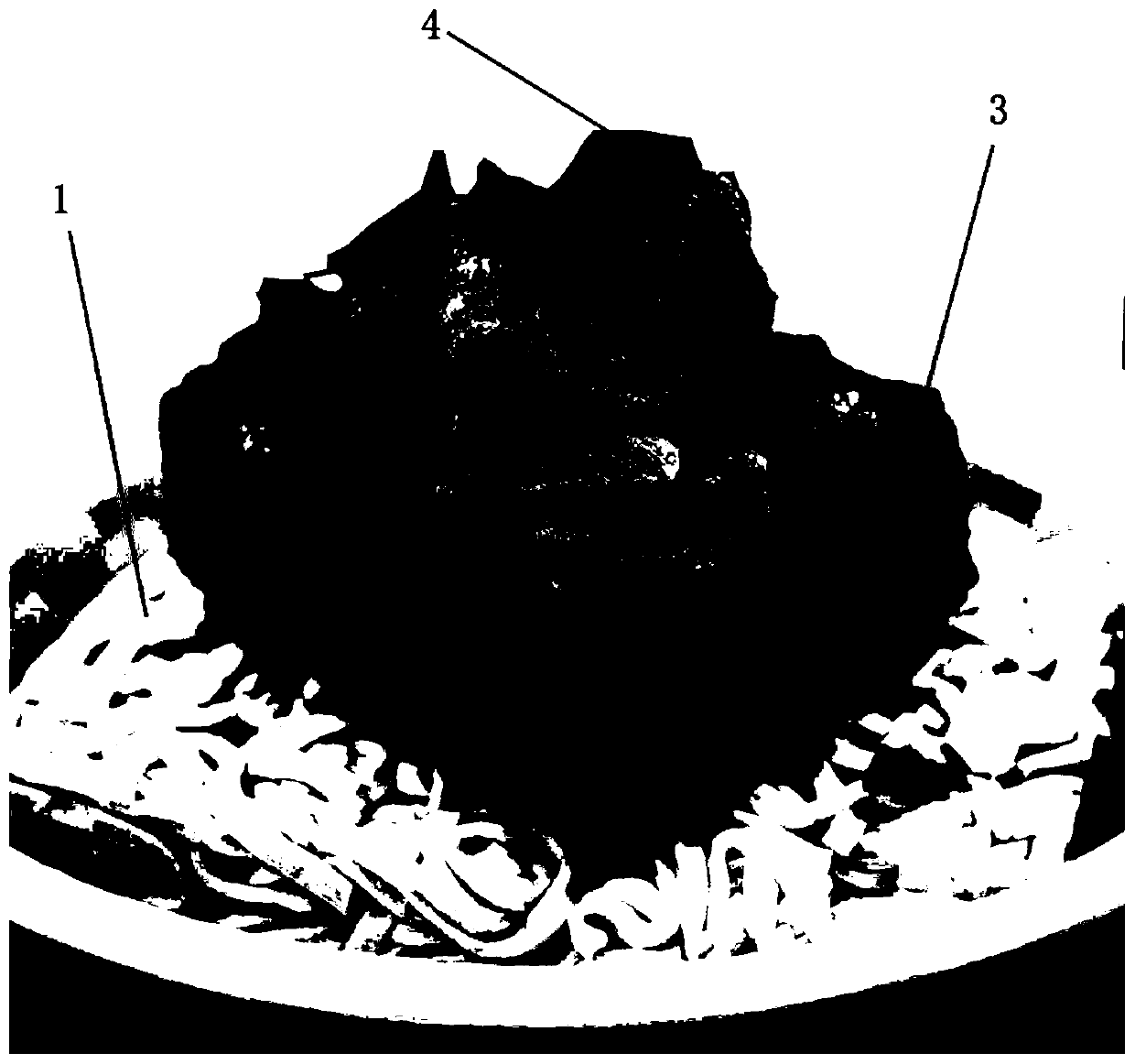

[0066] A kind of preparation method of freeze-dried sour tomato beef noodles is prepared according to the following components:

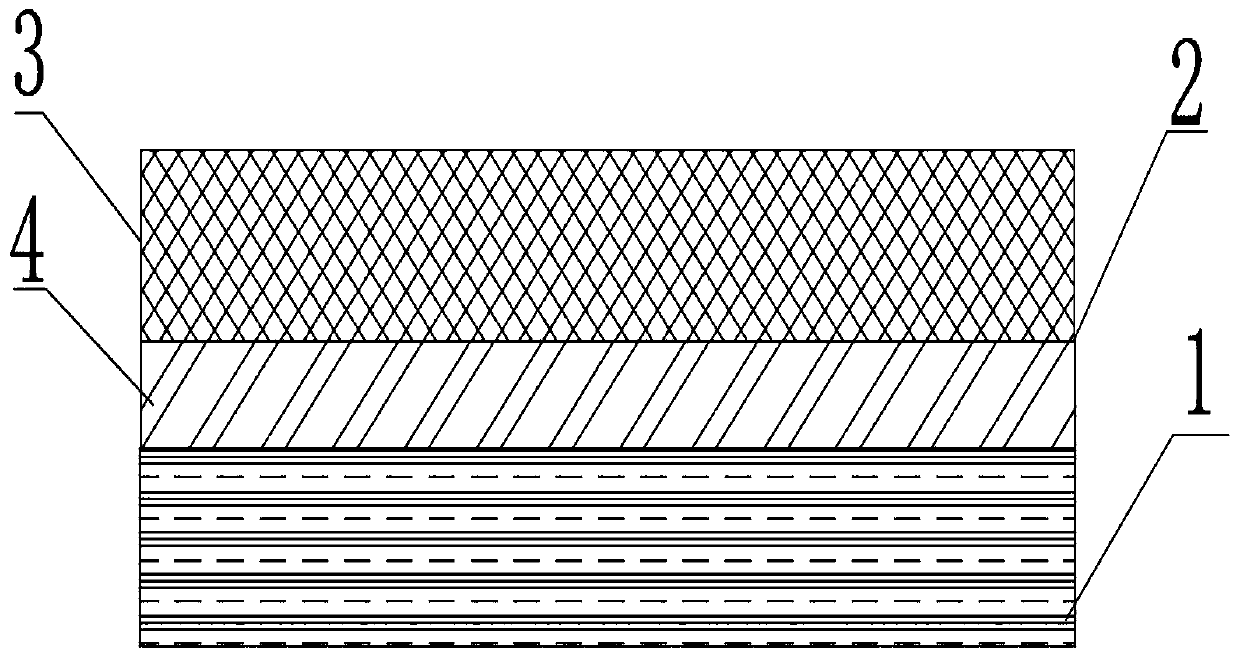

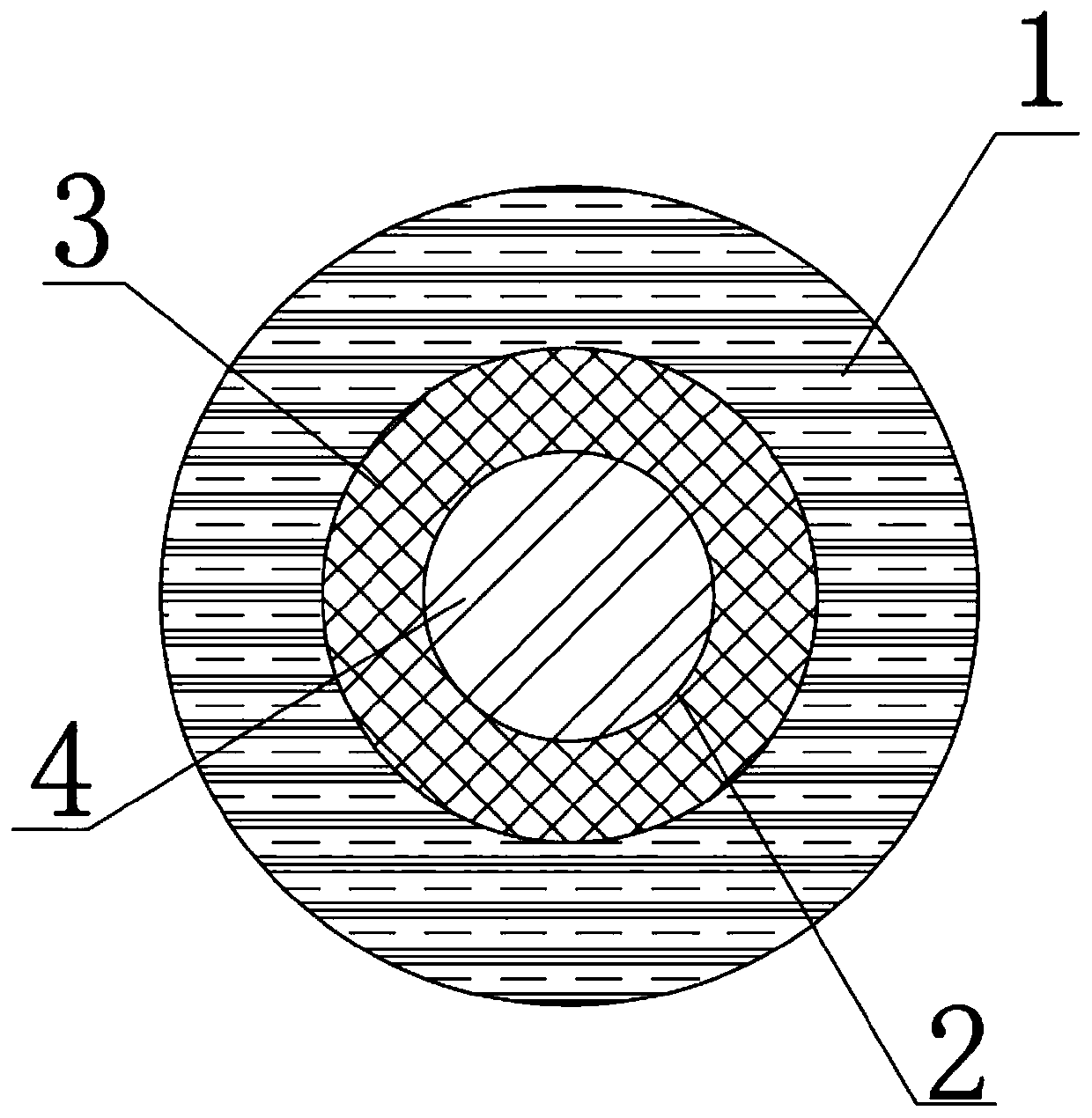

[0067] The material includes a surface layer and a material layer; the material layer includes tomato composite material and beef, in parts by weight, the surface layer is 80 parts by weight; the material layer is 65 parts by weight; beef is 25 parts by weight, and tomato composite material is 41 parts by weight.

[0068] The tomato composite material includes tomatoes, cabbage and filling ingredients; in parts by weight, 8 parts by weight of the tomato; 6 parts by weight of the cabbage and 27 parts by weight of the filling ingredients, wherein the filling ingredients include, Eggs, edible starch, maltodextrin, edible salt, chicken powder, edible vegetable oil.

[0069] The above components are prepared by controlling the material soaking penetration and freeze-drying parameters to coordinately dry the frozen material:

[0070] Cutting: before soak...

Embodiment 2

[0077] A kind of preparation method of freeze-dried hot and sour flavor tomato beef noodles, prepares materials according to following components:

[0078] The material includes a surface layer and a material layer; the material layer includes tomato combination material and beef, in parts by weight, 250 parts by weight of the surface layer; 243 parts by weight of the material layer; 100 parts by weight of beef, and 143 parts by weight of tomato combination material.

[0079] The tomato composite material includes tomatoes, cabbage and filling ingredients; in parts by weight, 31 parts by weight of the tomato; 22 parts by weight of the cabbage and 90 parts by weight of the filling ingredients, wherein the filling ingredients include, Shrimp, broccoli, broth, vinegar powder, seasoning sauce, chili oil.

[0080] The above components are prepared by controlling the material soaking penetration and freeze-drying parameters to coordinately dry the frozen material:

[0081] Soaking;...

Embodiment 3

[0087] A kind of preparation method of freeze-dried green onion tomato beef noodles, prepare materials according to following components:

[0088] The material includes a surface layer and a material layer; the material layer includes tomato combination material and beef, in parts by weight, 161 parts by weight of the surface layer; 160.4 parts by weight of the material layer; 65 parts by weight of beef, and 95.4 parts by weight of tomato combination material.

[0089] The tomato composite material includes tomatoes, cabbage and filling ingredients; in parts by weight, 20.4 parts by weight of the tomatoes; 14.8 parts by weight of the cabbage and 60.2 parts by weight of the filling ingredients, wherein the filling ingredients include, Oyster mushroom, fungus, pepper rings, shallots, edible salt, edible gum, starch phosphate, acetate starch, edible vegetable oil, hydrolyzed vegetable protein, yeast extract.

[0090] The above components are prepared by controlling the material s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com