A sewage treatment system

A sewage treatment system and treatment tank technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. , debris impact and other problems, to improve the solid-liquid separation efficiency, facilitate the filtration work, and ensure the effect of the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

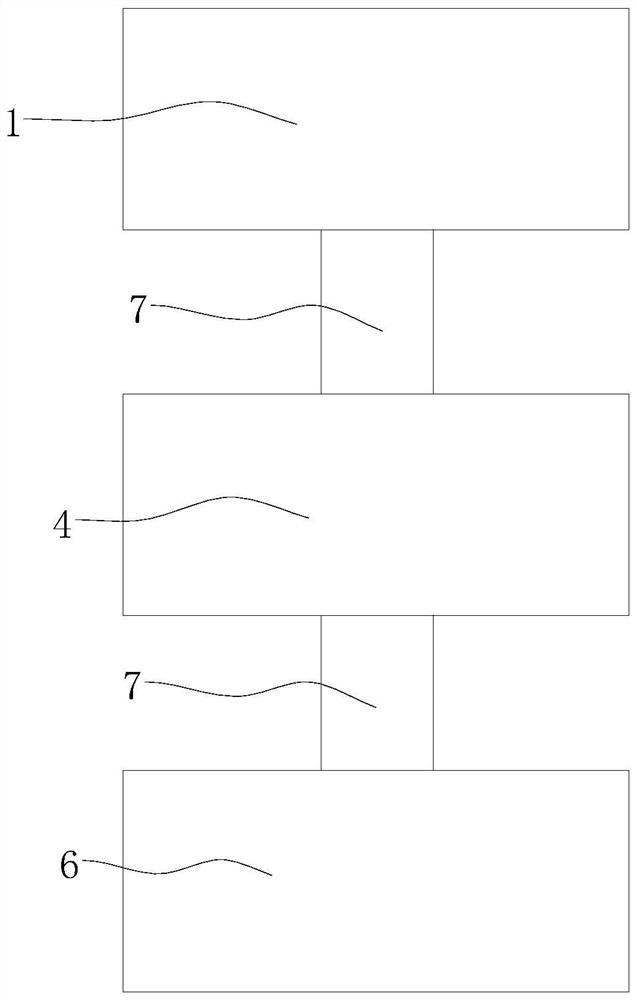

[0043] refer to figure 1 , is a sewage treatment system disclosed by the present invention, comprising a pretreatment device 1, a settling tank 4, a regulating tank 5 and a water storage tank 6 arranged in sequence and communicated with each other through a water delivery pipe 7; the pretreatment device 1 and the factory sewage discharge The water pipe 7 between the regulating pool 5 and the reservoir 6 is provided with a regulating valve (not shown in the figure), and chemical substances are put into the regulating pond 5 to neutralize the sewage; the factory sewage is processed by the pretreatment device 1 After the pretreatment, impurities are precipitated in the sedimentation tank 4, and then the sewage is regulated in the regulating tank 5, and then transported to the storage tank 6 for storage for other purposes, or discharged.

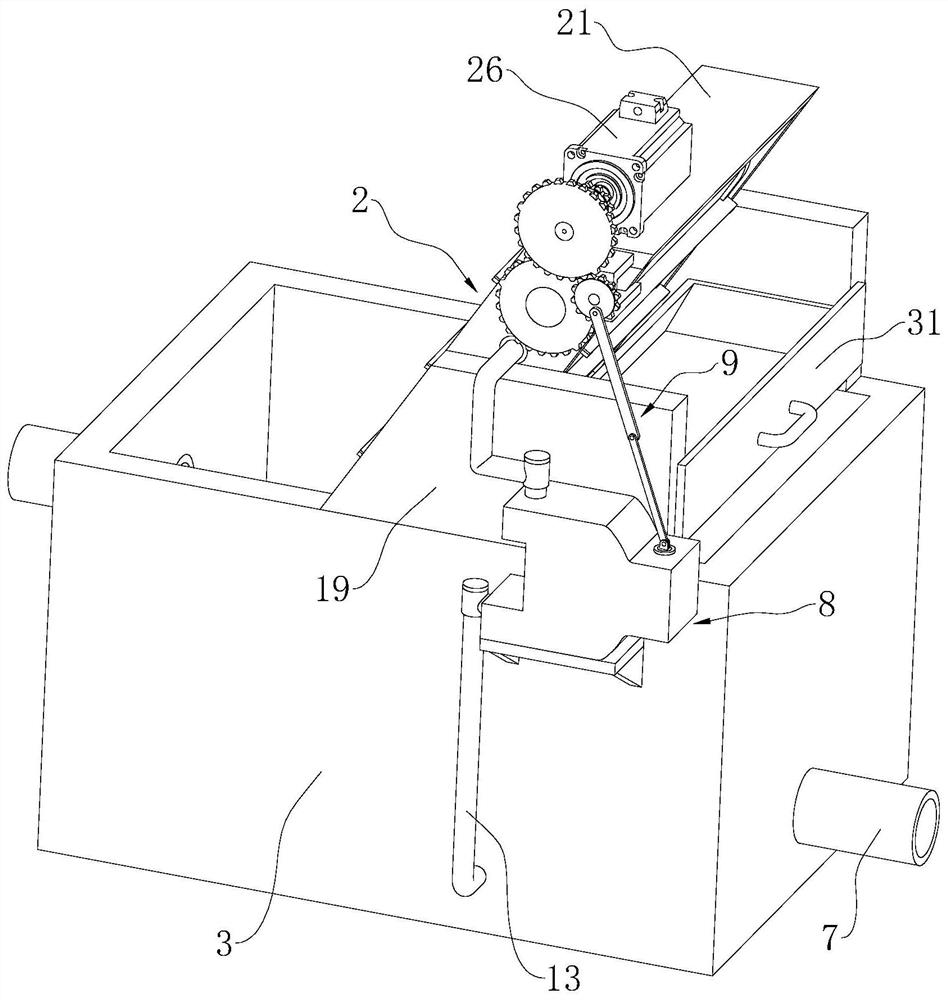

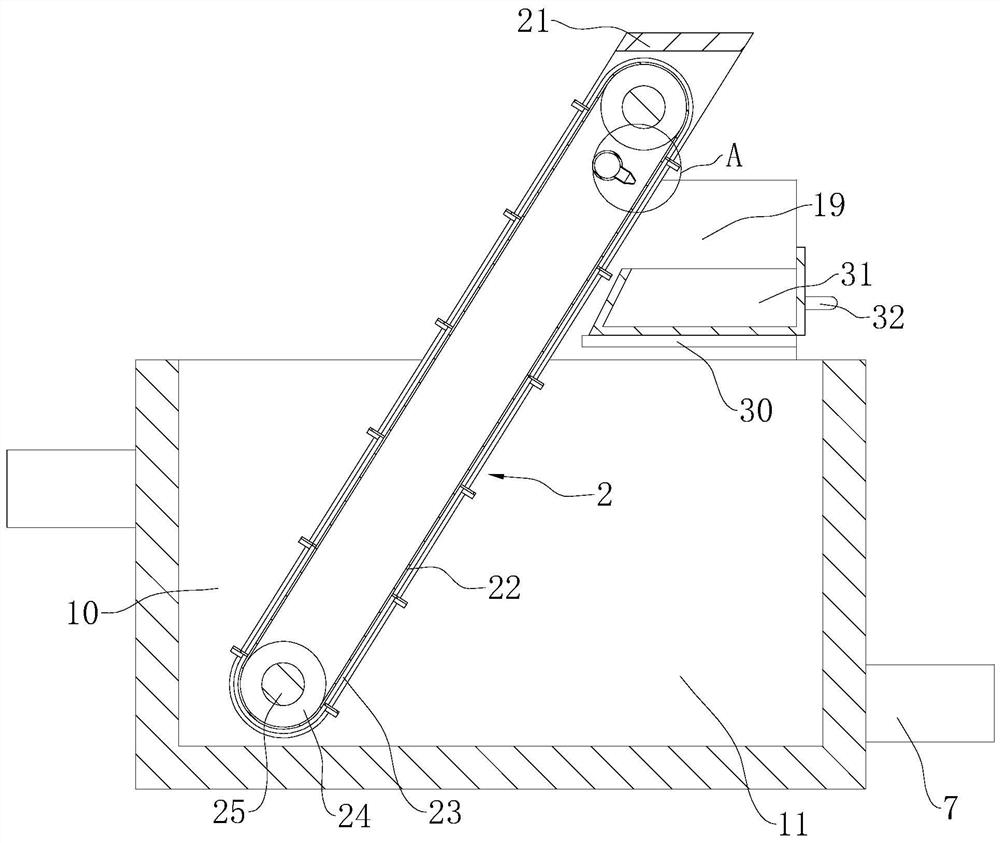

[0044] refer to figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com