Method for preparing monatomic catalyst by atomizing precursor

A technology of catalysts and precursors, which is applied in the field of preparation of single-atom catalysts by atomization of precursors. It can solve the problems of complex equipment requirements, poor adjustability, and low preparation volume, and achieve simple preparation methods, low cost, and meet the requirements of experimental diversification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

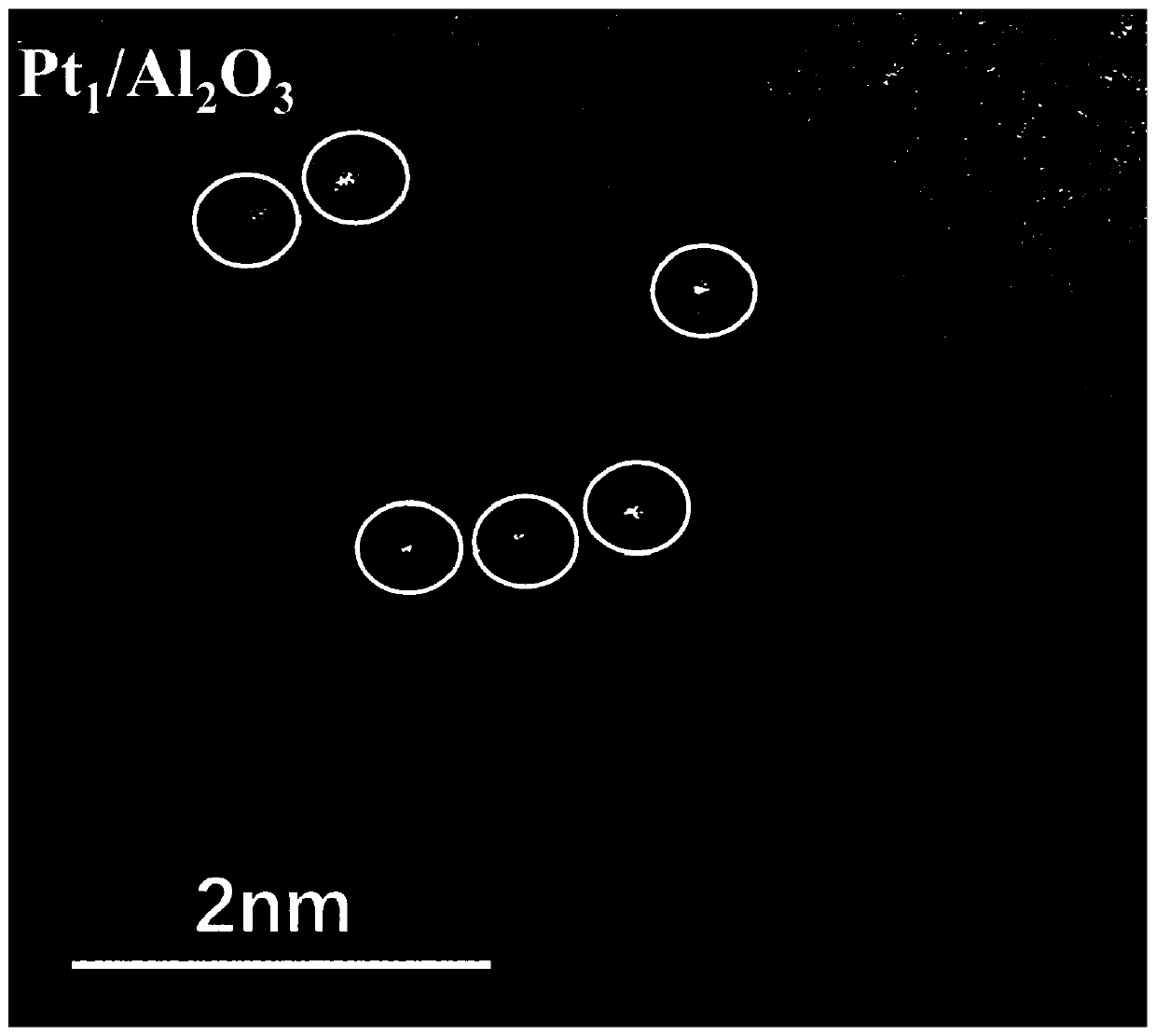

[0044] Take a 500 ml clean beaker, add 400 ml deionized water, and dissolve 0.1 g of tetraammine platinum nitrate in 400 ml of deionized water. Prepare a clean glass plate (9 cm×9 cm size), weigh 1 g of alumina with a balance, and spread the alumina powder on the glass plate. Then place the spray head 20 cm above the glass plate, introduce the pre-dissolved precious metal salt solution into the spray head, turn on the power and turn on the switch, and start spraying the solution, which is sprayed onto the flat alumina surface of the glass plate.

[0045] Spray for about 1 minute, and stop spraying after power off. Turn on the infrared light, make the light shine on the glass plate covered with alumina, and stop the infrared light for about 1 minute. Then spray the solution for 1 min, and irradiate the infrared lamp for 1 min, and then cycle 100 times. (This power-on and power-off cycle process is automatically completed by a smart socket with programming)

[0046] Place the abov...

Embodiment 2

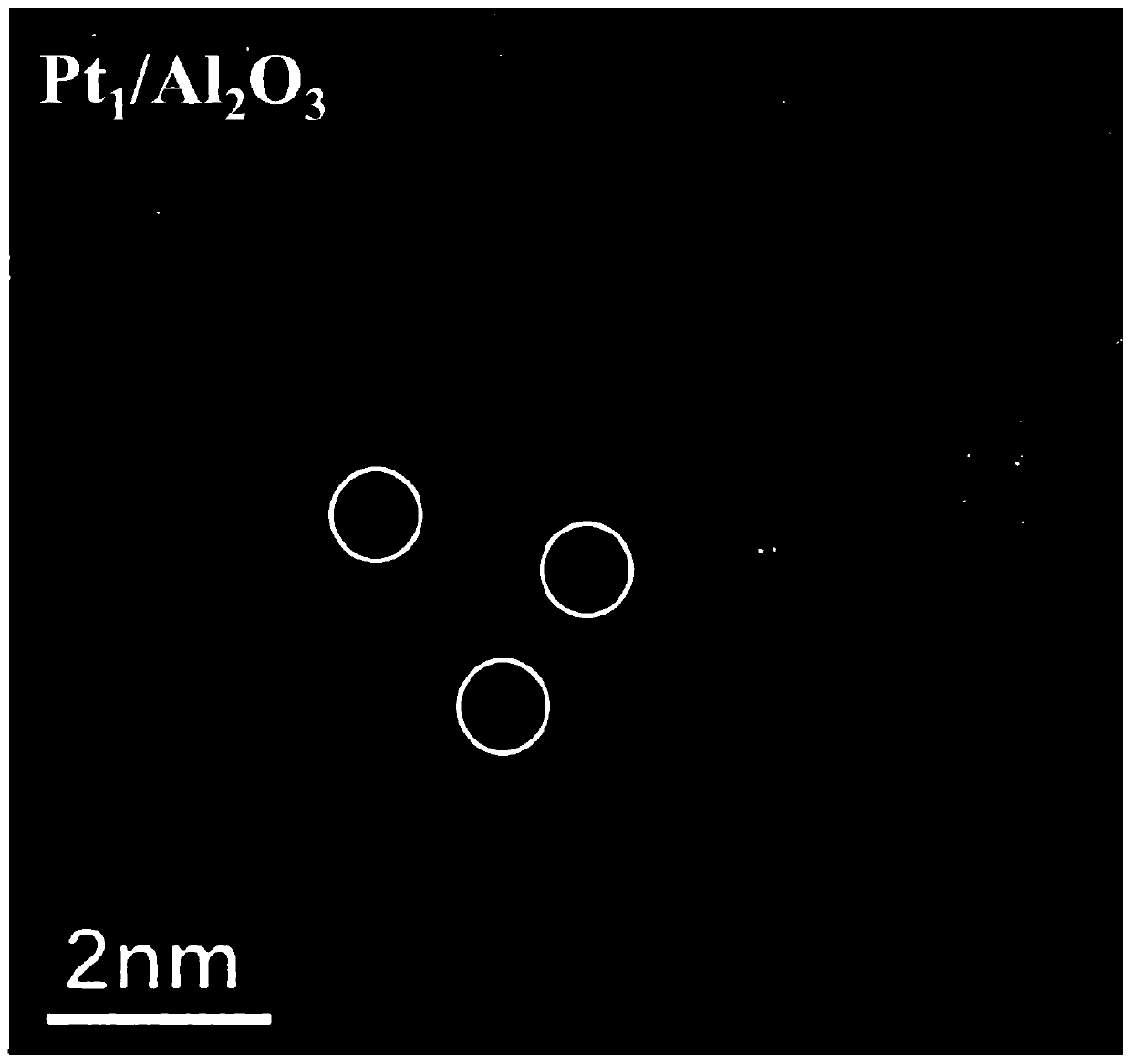

[0048] Take a 250 ml clean beaker, add 120 ml acetone, and dissolve 0.03 g platinum acetylacetonate in 120 ml acetone. Prepare a clean glass plate (9 cm ´ 9 cm size), weigh 1 g of zinc oxide with a balance, and spread the zinc oxide powder on the glass plate. Then place the spray head 20 cm above the glass plate, introduce the pre-dissolved precious metal salt solution into the spray head, turn on the power and turn on the switch to start spraying the solution and spray it on the flat zinc oxide surface of the glass plate.

[0049] Spray for about 2 minutes, and stop spraying after power off. Turn on the infrared light, make the light shine on the glass plate covered with zinc oxide, and stop the infrared light for about 2 minutes. Then spray the solution for 2 minutes, and irradiate the infrared lamp for 2 minutes, and so on for 50 times. (This power-on and power-off cycle process is automatically completed by a smart socket with programming)

[0050] Place the above-prepared m...

Embodiment 3

[0052] Take a clean 1000 ml beaker, add 800 ml of absolute ethanol, and dissolve 0.1 g of palladium chloride in 800 ml of absolute ethanol. Prepare a clean glass plate (9 cm ´ 9 cm size), weigh 1 g of magnesium oxide with a balance, and spread the magnesium oxide powder on the glass plate. Then place the spray head 20 cm above the glass plate, introduce the pre-dissolved precious metal salt solution into the spray head, turn on the power and turn on the switch to start spraying the solution and spray it onto the flat magnesium oxide surface of the glass plate.

[0053] Spray for about 1 minute, and stop spraying after power off. Turn on the infrared light, make the light shine on the glass plate covered with magnesium oxide, and stop the infrared light for about 1 min. Then spray the solution for 1 min, and irradiate the infrared lamp for 1 min, and repeat 200 times. (This power-on and power-off cycle process is automatically completed by a smart socket with programming)

[0054...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com