A kind of fenicusn pre-alloyed powder, preparation method and application

A pre-alloyed powder and powder technology, which is applied in the field of preparation, FeNiCuSn pre-alloyed powder, can solve the problems of uneven density distribution of green compact, low bulk density of fine powder, deterioration of mechanical properties, etc., to avoid serious powder agglomeration Sintering, solving the effect of poor cold press formability of ultrafine powder, and promoting the interdiffusion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

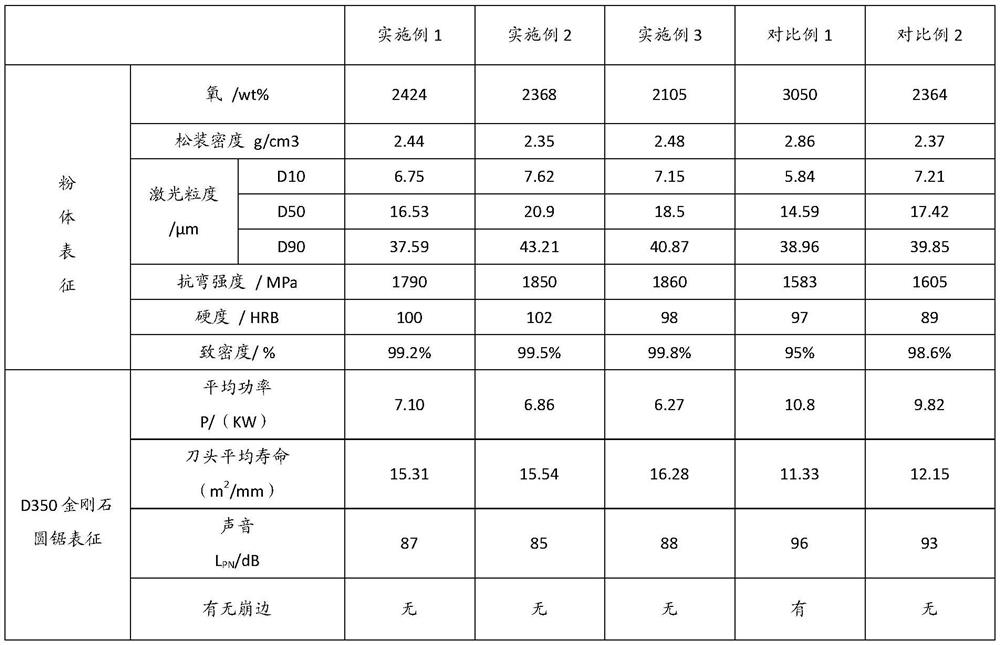

Examples

Embodiment 1

[0034]The FeNiCuSn pre-alloyed powder has the following components by weight: 30.00% Cu, 3.0% Ni, 4.0% Sn, 0.3% Si, 1.0% Ti, 0.5% Cr, 0.8% Mo, and the balance Fe; among which CuSn15 is pre-alloyed The ratio of powder precursor and ultrafine FeNiCuSn pre-alloyed powder precursor is 5:95. The corresponding weight percentage of the precursor of the ultrafine FeNiCuSn pre-alloyed powder is:

[0035] 3.16wt%Ni-27.1wt%Cu-3.4%Sn-0.31wt%Si-1.05wt%Ti-0.53wt%Cr-0.84wt%Mo, balance Fe.

Embodiment 2

[0037] The FeNiCuSn pre-alloyed powder has the following components by weight: 35.00% Cu, 4.0% Ni, 3.0% Sn, 0.2% Si, 1.0% Ti, 0.5% Cr, 1.2% Mo, and the balance Fe; among which CuSn15 is pre-alloyed The ratio of powder precursor and ultrafine FeNiCuSn pre-alloyed powder precursor is 7:93. The corresponding weight percentage of the precursor of the ultrafine FeNiCuSn pre-alloyed powder is:

[0038] 4.3wt%Ni-31.24wt%Cu-2.1%Sn-0.22wt%Si-1.07wt%Ti-0.54wt%Cr-1.3wt%Mo, balance Fe.

[0039] The invention also provides a preparation method of FeNiCuSn pre-alloyed powder. Two kinds of precursors are prepared by means of ultra-high pressure water-gas combined atomization powder preparation: CuSn15 pre-alloyed powder precursor and ultra-fine FeNiCuSn pre-alloyed powder precursor; The prepared two precursors are fully mixed and uniform in a certain proportion, and the weight percentages are: CuSn15 pre-alloy powder precursor 2-10%, ultrafine FeNiCuSn pre-alloy powder precursor 90-98%; and...

Embodiment 1

[0062] A preparation method suitable for FeNiCuSn pre-alloyed powder for diamond tools, comprising:

[0063] 1) Intermediate frequency induction melting: FeNiCuSn pre-alloy powder alloy composition weight percentage is Fe-3.0wt%Ni-30.0wt%Cu-4.0wt%Sn-0.3wt%Si-1.0wt%Ti-0.5wt%Cr-0.8wt% Mo. Among them, the weight percentage of the prepared FeNiCuSn pre-alloy powder precursor is: Fe-3.16wt%Ni-27.1wt%Cu-3.4%Sn-0.31wt%Si-1.05wt%Ti-0.53wt%Cr-0.84wt%Mo , CuSn15 pre-alloyed powder precursor composition is Cu-15wt% Sn.

[0064] According to the composition of the two precursor alloys, pure iron, pure nickel, titanium iron, molybdenum iron, pure copper, pure tin, high-purity silicon and ferrochromium are selected respectively. , the smelting time is 40.0-70.0 minutes, when the temperature of the molten steel reaches ≥1620 °C, the power is reduced to 60-80KW, and the alloying process of the molten steel is 5.0-10.0 minutes, then the slag is cleaned, and the pump is poured into the steel;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com