Consumption reduction and efficiency improvement system and method suitable for oxidation ditch biological denitrification

A biological denitrification and oxidation ditch technology, which is applied in the system field of reducing consumption and improving efficiency, can solve the problem that it is difficult to control the process parameters in a reasonable range, the effluent water quality cannot reach the ideal target, and the excessive consumption of carbon source and aeration air volume and other problems, to achieve the effect of precise control of aeration volume, high degree of automation, and reduced operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below through specific embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the following specific embodiments.

[0050] The embodiments provided below are not intended to limit the scope of the present invention, and the described steps are not intended to limit the execution sequence thereof, and the described directions are only limited to the accompanying drawings. Obvious improvements made by those skilled in the art in combination with existing common knowledge also fall within the scope of protection required by the present invention.

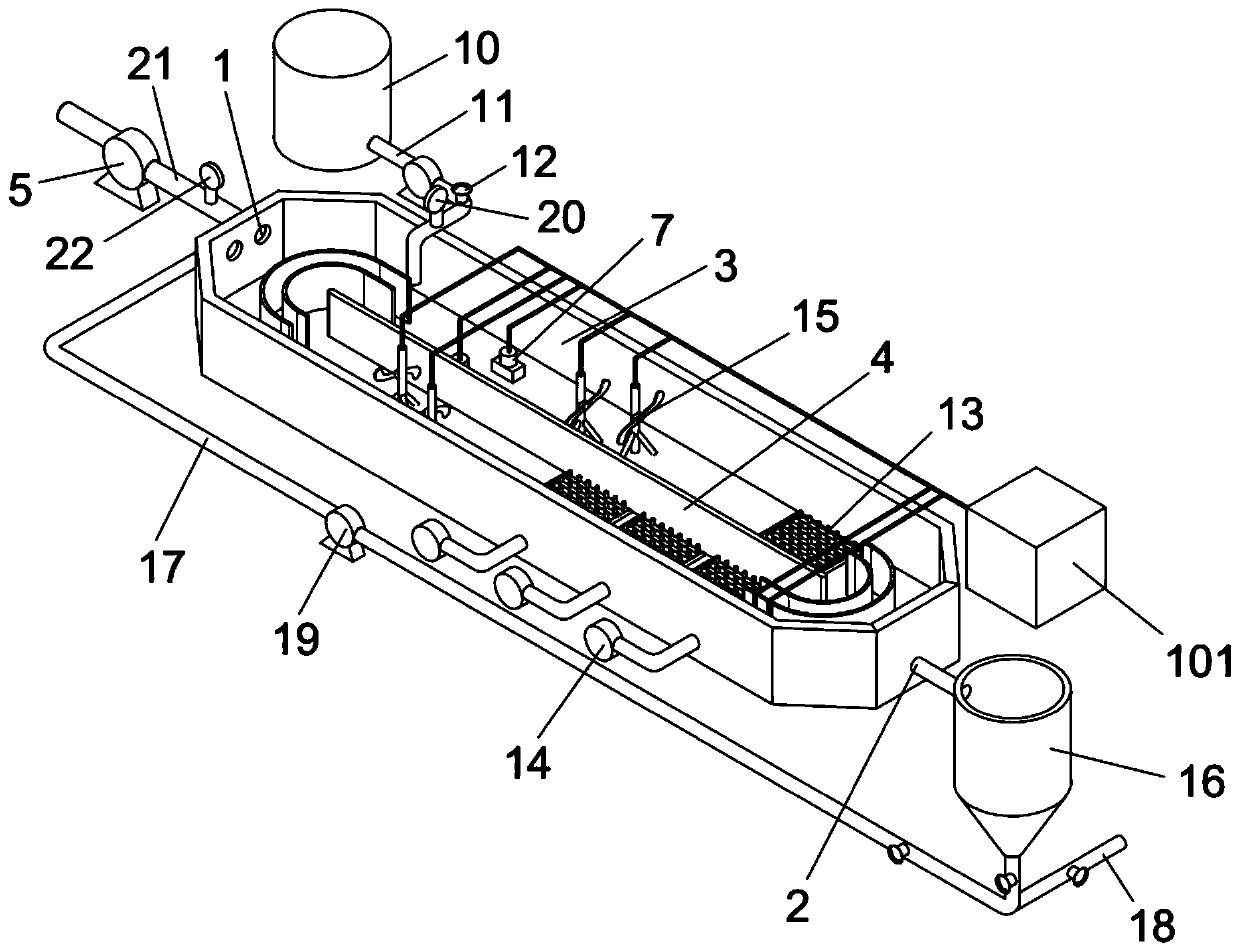

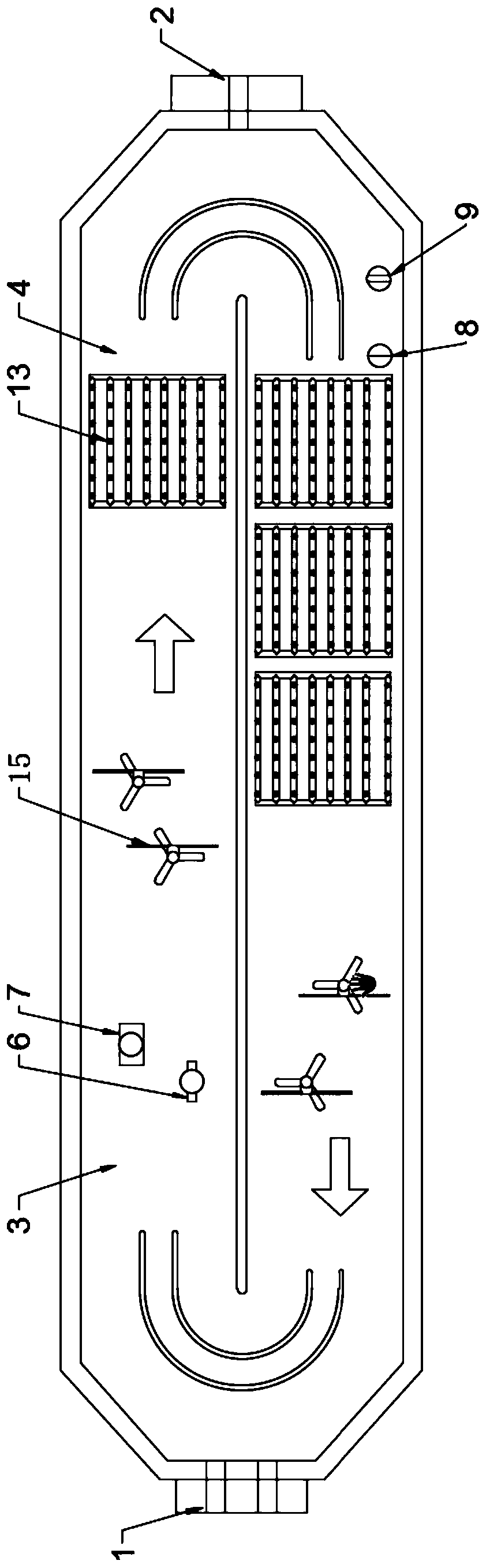

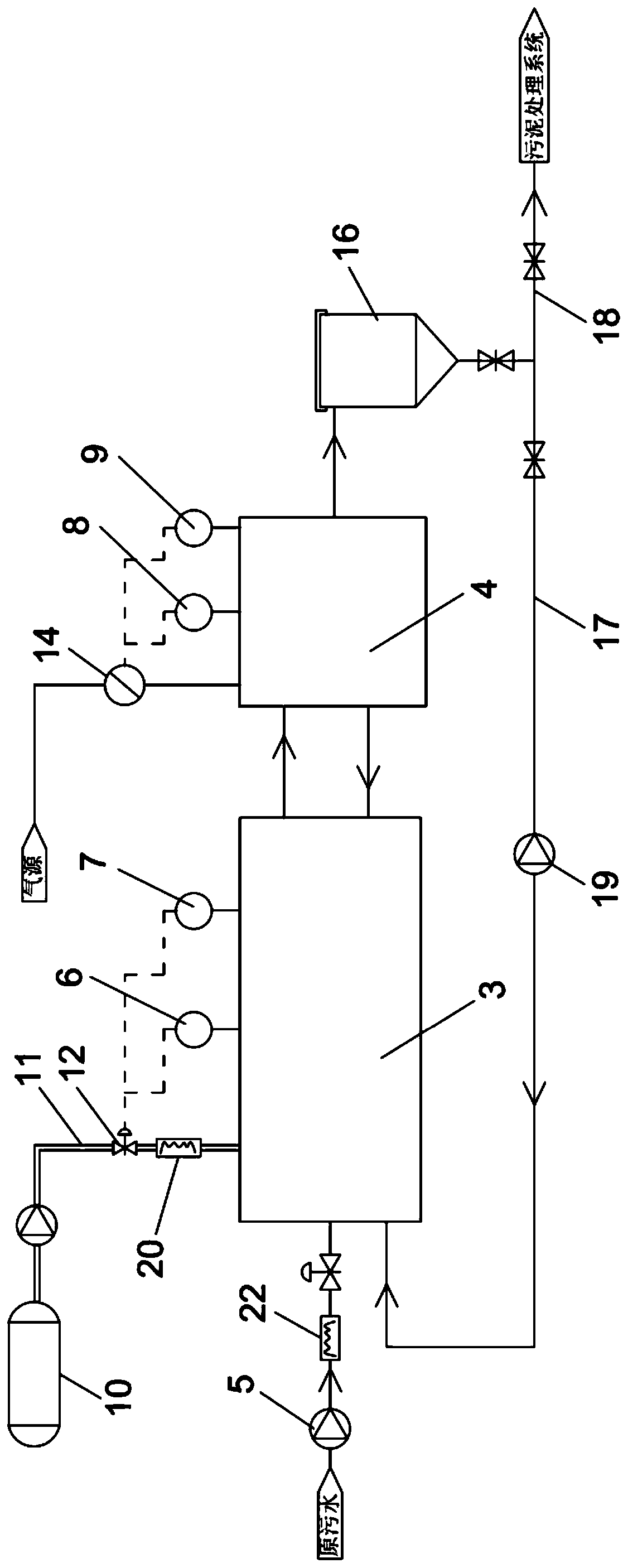

[0051] A system suitable for reducing consumption and improving efficiency of oxidation ditch biological denitrification, such as Figure 1 to Figure 3 As shown, it includes a biological reaction zone, which is divided into a non-aeration zone 3 near the front water inlet 1 side and an aeration zone 4 near the rear water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com