Aniline trimer modified sulfonate type waterborne epoxy curing agent and preparation method thereof

An aniline trimer and water-based epoxy technology, applied in the field of polymer materials, can solve the problem of not developing aniline oligomer anti-corrosion fillers or modified materials, etc., and achieve excellent anti-corrosion performance, thermal stability, high hardness, Strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Prepare aniline trimer modified sulfonate water-based epoxy curing agent according to the following steps:

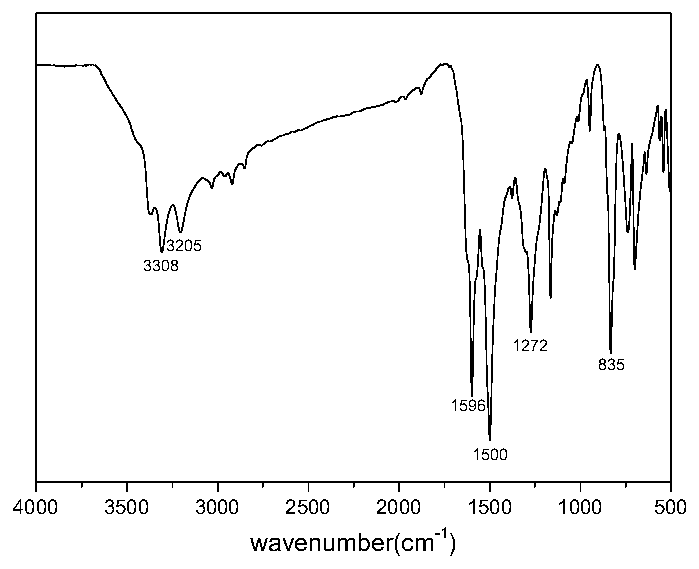

[0057] Add 1.73g of p-phenylenediamine sulfate dissolved in 100mL of hydrochloric acid solution (1.0mol / L) into a three-necked flask, cool down to -5°C, add 3.65g of ammonium persulfate and stir evenly, then quickly add 2.98g of aniline solution and keep The temperature of the system is between -5-0°C for 1 hour. After the reaction, the product is filtered and washed with 10% ammonia water and deionized water until the filtrate is neutral, and the solid product is dried to obtain aniline trimer (AT). Until the filtrate is neutral, it is finally placed in a vacuum oven at 50°C for 24 hours to prepare AT for use.

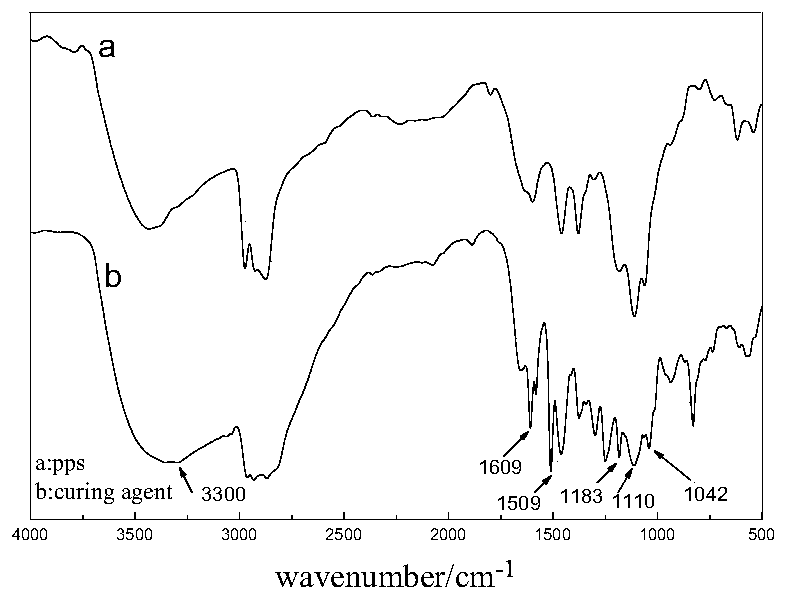

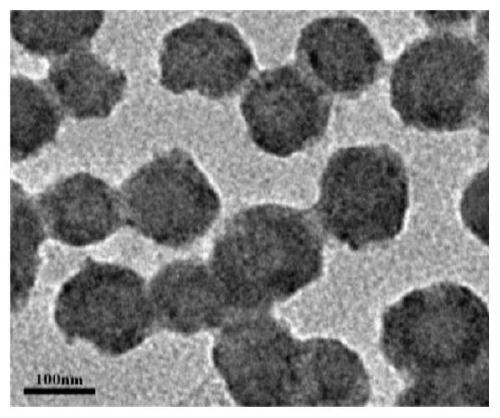

[0058] 94.5g tetraethylenepentamine (TEPA) is added in the there-necked flask, and 2.9g aniline trimer AT (AT accounts for TEPA and AT total mole fraction is 2%) is dissolved in the propylene glycol methyl ether and is added in the TEPA, control At a t...

Embodiment 2

[0069] Prepare aniline trimer modified sulfonate water-based epoxy curing agent according to the following steps:

[0070] Add 4.33g of p-phenylenediamine sulfate dissolved in 150mL of hydrochloric acid solution (1.0mol / L) into a three-necked flask, cool down to -5°C, add 11.52g of ammonium persulfate solution and stir evenly, then quickly add 7.44g of aniline solution, Keep the temperature of the system at -5-0°C and react for 1 hour. After the reaction is over, filter and wash the product with 10% ammonia water and deionized water until the filtrate is neutral, and dry the solid product to obtain aniline trimer body (AT). Until the filtrate is neutral, it is finally placed in a vacuum oven at 50°C for 24 hours to prepare AT for use.

[0071] Add 73.0g of triethylenetetramine (TETA) into the three-necked flask, and weigh 6g of aniline trimer AT (AT accounts for 4% of the total mole fraction of TETA and AT) and dissolve it in propylene glycol methyl ether and add it to TETA, ...

Embodiment 3

[0077] Prepare aniline trimer modified sulfonate water-based epoxy curing agent according to the following steps:

[0078] Add 8.65g of p-phenylenediamine sulfate dissolved in 200mL of hydrochloric acid solution (1.0mol / L) into a three-necked flask, cool down to -5°C, add 21.89g of ammonium persulfate solution and stir evenly, then quickly add 18.6g of aniline solution, Keep the temperature of the system at -5-0°C and react for 1 hour. After the reaction is over, filter and wash the product with 10% ammonia water and deionized water until the filtrate is neutral, and dry the solid product to obtain aniline trimer body (AT). Until the filtrate is neutral, it is finally placed in a vacuum oven at 50°C for 24 hours to prepare AT for use.

[0079] Add 51.5g of diethylenetriamine (DETA) into the three-necked flask, and weigh 12.5g of aniline trimer AT (AT accounts for 8% of the total molar fraction of TETA and AT) in addition, dissolve it in propylene glycol methyl ether and add i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com