Fluorescent microspheres and preparation method and fluorescence coding method thereof

A fluorescent microsphere and microsphere technology, applied in chemical instruments and methods, luminescent materials, particle and sedimentation analysis, etc., can solve the problems of fluorescence quenching, inability to meet biochemical detection, affecting the detection of fluorescent signals by instruments, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing fluorescent microspheres according to one embodiment includes the following steps S1-S2.

[0032] Step S1: Activating the microspheres by mixing them with a silane reagent and a solvent to obtain activated microspheres; wherein the silane reagents are epoxy silane reagents, chlorosilane reagents, isocyanate silane reagents, succinic anhydride silane reagents and chlorine At least one of the sulfonylphenylsilane reagents.

[0033] The use of the above-mentioned silane reagents does not require acidic or alkaline conditions to catalyze, and can directly interact with microspheres to activate microspheres under neutral conditions, and form epoxy groups, chlorine groups, isocyanate groups, succinic anhydride groups or Chlorosulfonylphenyl, in addition, it also avoids the problem of poor activation effect caused by ring opening or hydrolysis of these groups under acidic or alkaline conditions; the prepared active microspheres do not need coupling agent...

Embodiment 1

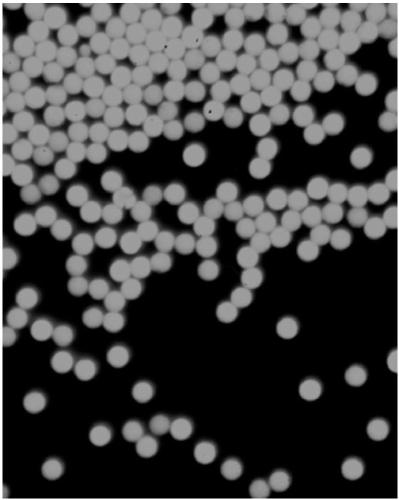

[0077] Surface activation of microspheres: add 30mL deionized water and 1mL of 20mg / mL Fe to a 250mL three-neck flask 3 o 4 The microsphere solution and 1 mL of epoxy silane reagent (3-glycidyloxypropyltriethoxysilane) were stirred at 200 rpm and 50° C. for 24 hours to obtain epoxy-modified activated microspheres. Fe 3 o 4 The particle size of the microspheres is 5 microns.

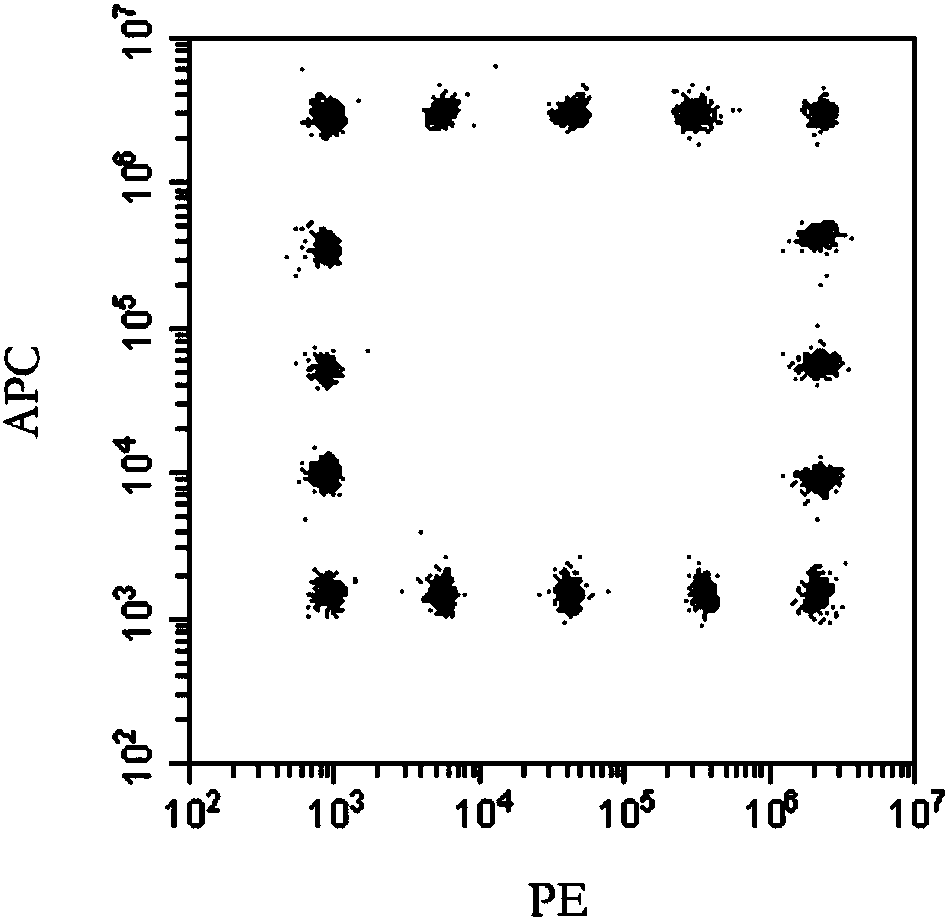

[0078] Microsphere-coupled fluorescent dye: Add 30 mL of deionized water, the above epoxy-modified activated microsphere and 80 μL of 1 mg / mL PE fluorescent dye into a 250 mL three-neck flask, stir at 200 rpm and 30 °C for 24 h, that is Microspheres with PE fluorescence were obtained.

Embodiment 2

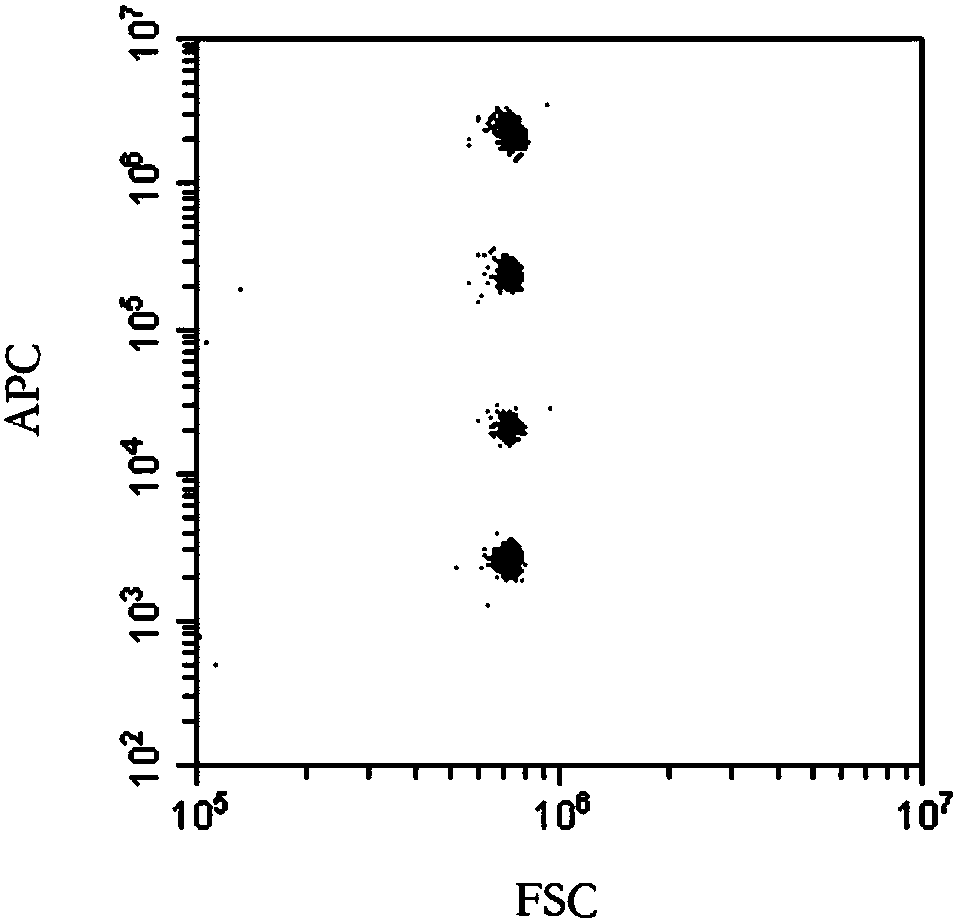

[0080] It is basically the same as Example 1, except that the fluorescent dye is APC, that is, 10 μL, 30 μL, 60 μL, and 120 μL of 1 mg / mL APC dye solution are added to obtain microspheres with four different APC fluorescence intensities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com