A low-cost rh decarburization and dephosphorization method

A low-cost, decarburization technology, applied in the metallurgical field, can solve the problems of large cost input, high equipment requirements, and high production costs, and achieve the effects of increasing slag consumption, high equipment requirements, and high production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

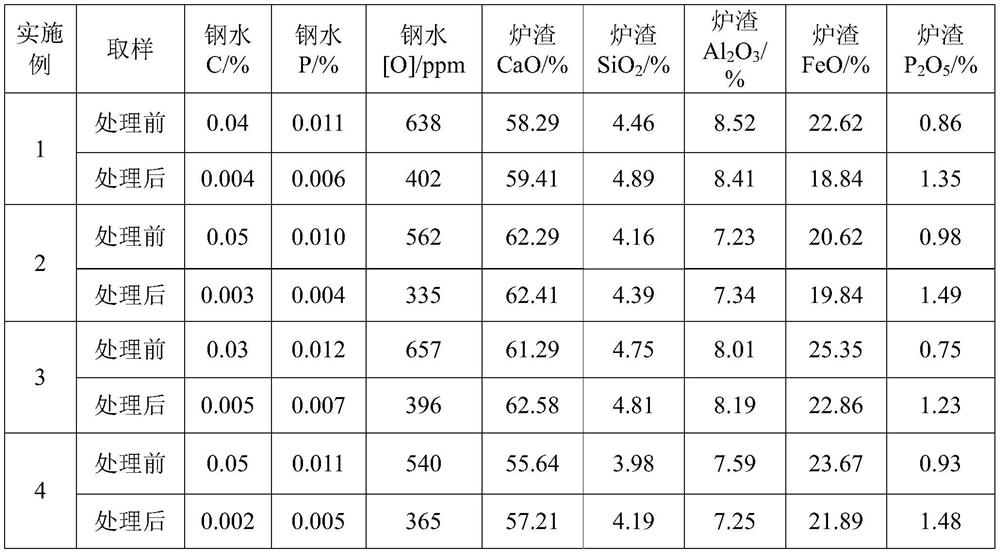

Embodiment 1

[0026] (1) Converter tapping C: 0.04%, P: 0.011%, tapping temperature 1635°C, adding 800kg lime + 400kg slagging agent from tapping 1 / 2 to the end of tapping, without adding alloy and deoxidizer.

[0027] (2) After tapping with argon flow rate of 800Nl / min and stirring for 3 minutes, the slag on the surface of the molten steel is melted and has good fluidity.

[0028] (3) The molten steel is hoisted to the RH treatment position, the temperature is 1591°C, the oxygen is determined to be 638ppm with an oxygen meter, the ladle is lifted to the RH treatment tank, the vacuum pump system is turned on for vacuum treatment, the molten steel in the vacuum chamber starts to circulate, and the vacuum degree is 12KPa at the beginning , the tail gas is all CO 2 , oxygen in molten steel starts to react with carbon and phosphorus, and with the CO in the tail gas 2 decrease and CO gradually increased, indicating that the carbon-oxygen reaction rate gradually increased, and at the same time t...

Embodiment 2

[0032] Converter tapping C: 0.05%, P: 0.010%, tapping temperature 1640°C, argon gas flow rate 700Nl / min and stirring for 4min after tapping, molten steel was hoisted to the RH treatment position, temperature 1598°C, and oxygen was determined by an oxygen meter 562ppm, RH cycle treatment for 7min, CO tail gas concentration in the vacuum chamber 0.3%, and maintain a stable state, temperature measurement is 1549°C, oxygen meter is 335ppm, molten steel sampling: C is 0.003%, P is 0.004%. null. All the other operations are the same as in Example 1.

Embodiment 3

[0034] Converter tapping C: 0.03%, P: 0.012%, tapping temperature 1646°C, argon gas flow rate 900Nl / min and stirring for 2min after tapping, molten steel was hoisted to RH treatment position, temperature 1593°C, oxygen was determined by oxygen meter 657ppm, RH cycle treatment for 6min, CO tail gas concentration in the vacuum chamber was 0.4%, and maintained a stable state, the temperature measurement was 1561°C, the oxygen was 396ppm by the oxygen meter, molten steel sampling: C was 0.005%, P was 0.007%, and the broken null. All the other operations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com