Composite thermal fabric and preparation method thereof

A technology for fabrics and fabric layers, applied in textiles and papermaking, fiber processing, electrospinning, etc., to achieve the effects of good practicability, accelerated surface temperature, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of the above-mentioned composite thermal fabric, the method comprising the following steps:

[0044] (1) Take graphene oxide and disperse it in deionized water; place the graphene oxide in deionized water, carry out ultrasonic dispersion for 40-50 minutes, the operating frequency during ultrasonic dispersion is 20-50kHZ, and the dispersion is completed to obtain graphene oxide dispersion liquid;

[0045] Preferably, the operating frequency during ultrasonic dispersion is 30-40kHZ.

[0046] (2) according to the required mass ratio, polyvinyl alcohol is dissolved in the graphene oxide dispersion of step (1) to swell, and the mass fraction of polyvinyl alcohol added is 5wt%~10wt% (and meets the requirements of polyvinyl alcohol and The mass ratio of graphene oxide is 7:0.1~7:0.5.), swelling after adding for 45~55min;

[0047]Then heat at 90-100° C. for 3-5 hours, and cool to room temperature after heating to obtain...

Embodiment 1

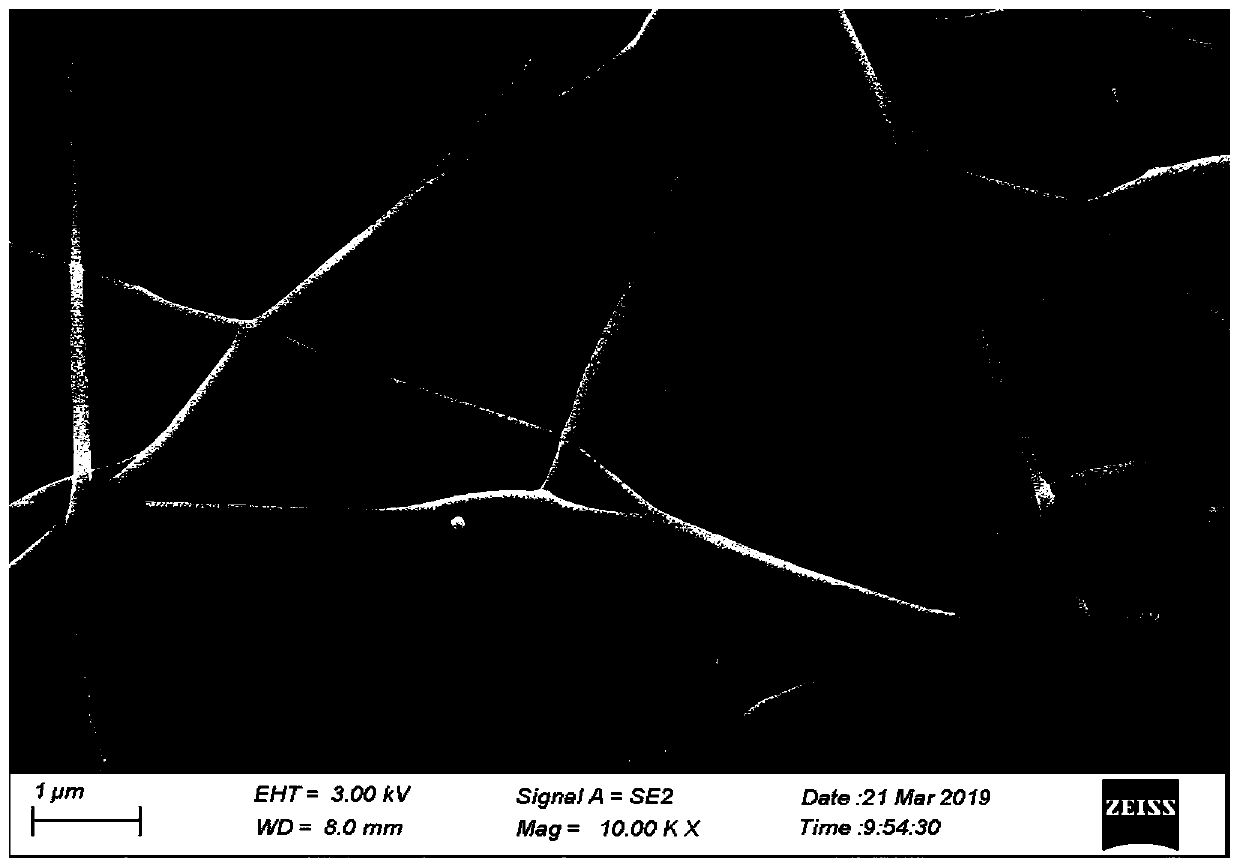

[0061] A kind of nanocomposite fiber, described nanocomposite fiber is prepared from polyvinyl alcohol, polyethylene glycol and graphene oxide, wherein polyvinyl alcohol 6g, the mass ratio of described polyvinyl alcohol and polyethylene glycol is 2: 1. The mass ratio of polyvinyl alcohol to graphene oxide is 7:0.1, the total amount is 100g, and the balance is water. The electron microscope image of the obtained fiber is shown in figure 1 shown.

Embodiment 2

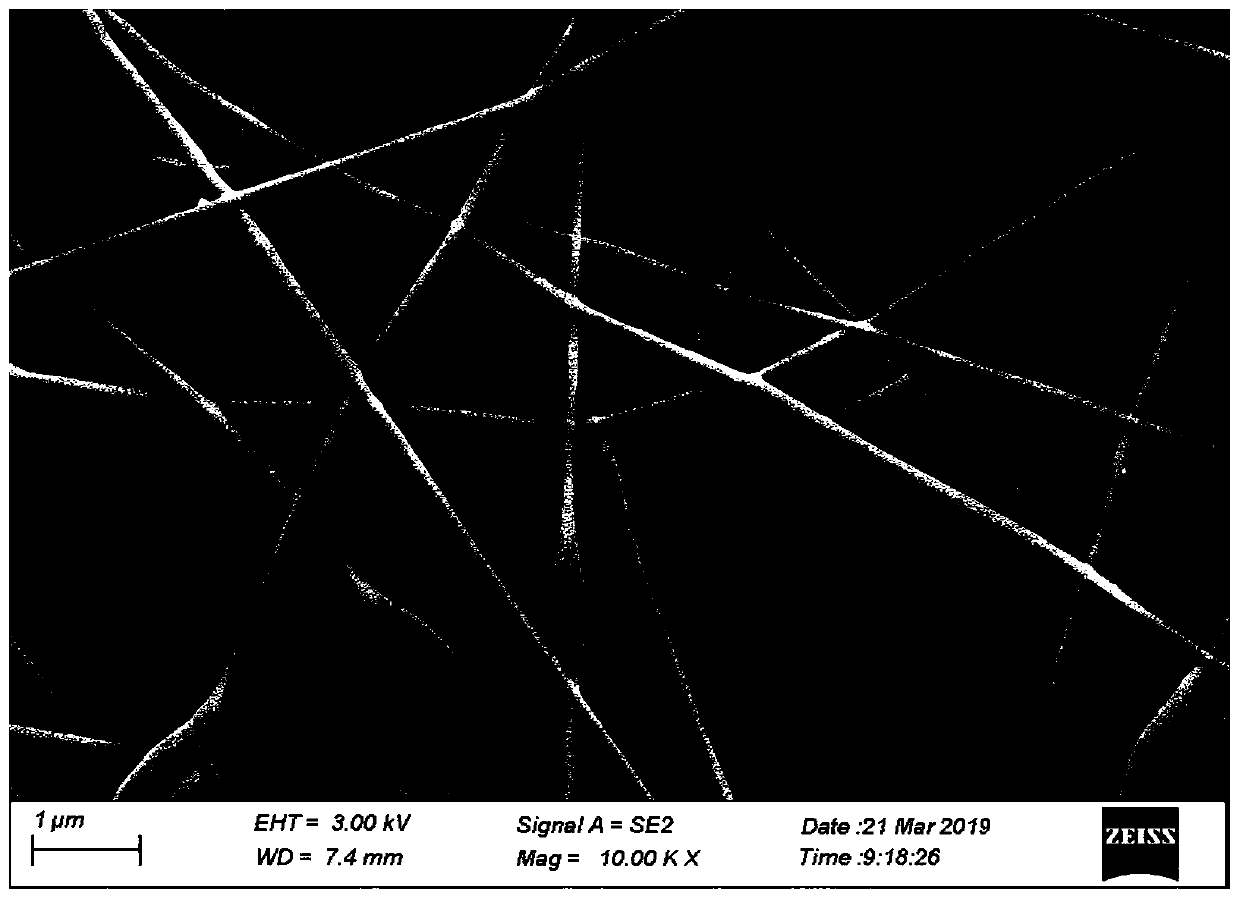

[0063] A kind of nanocomposite fiber, described nanocomposite fiber is prepared from polyvinyl alcohol, polyethylene glycol and graphene oxide, wherein polyvinyl alcohol 8g, the mass ratio of described polyvinyl alcohol and polyethylene glycol is 2.67: 1. The mass ratio of polyvinyl alcohol to graphene oxide is 7:0.1, the total amount is 100g, and the balance is water. The electron microscope image of the obtained fiber is shown in figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com