Agricultural and horticultural materials of knitwear or textiles containing Japanese paper yarn

A technology of paper yarn and knitwear, applied in the field of agricultural and gardening materials, can solve problems such as labor-intensive, inability to utilize hygroscopicity or moisture retention, reduce labor and expenses, increase diversity and activity value, and reduce vitamin content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、 comparative example 1

[0041] [Example 1, Comparative Example 1: multilayer sheet for agriculture and gardening]

[0042] (test 1)

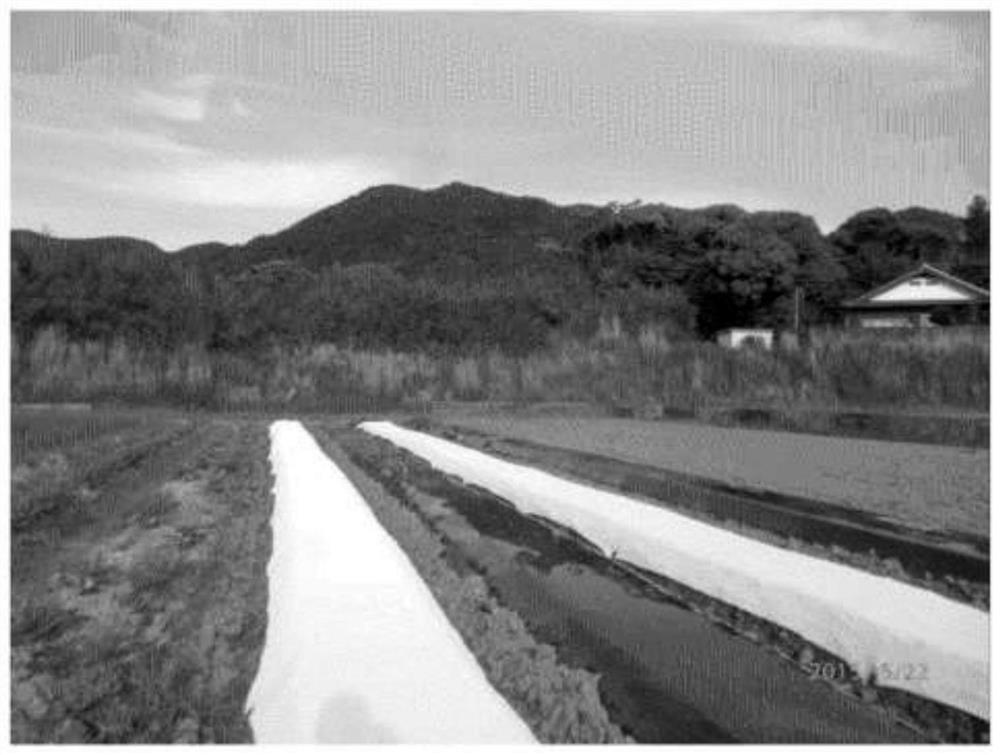

[0043] Various crops were cultivated on the farm using an agricultural multilayer sheet made of Japanese paper yarn (Example 1) or an agricultural multilayer sheet made of polyethylene (Comparative Example 1), and the growth state, Chlorophyll content, biodegradability in crops.

[0044]

[0045] The Japanese paper made from Manila banana is cut into 2.0mm width, and twisted 3 times (+600, -800, +1000T / m) by dry method to produce 240dtex Japanese paper yarn. After piqué knitting, it was washed with water and then dried to produce a knitwear with 10 stitches.

Embodiment 2、 comparative example 2

[0074] [Example 2, Comparative Example 2: Substrate for hydroponics]

[0075] Spread the Japanese paper yarn knitwear prepared in the same manner as in Example 1 on the bottom of a plastic container for hydroponic cultivation, form a mat and moisten it with water, such as Figure 3a Seeds of red mustard greens (left) and romaine lettuce (right) were sown on them and stored at room temperature. 6 days later, if Figure 3b As shown in (left: mustard greens, right: romaine lettuce), good germination was confirmed. Figure 3c It is a photo of red mustard greens harvested 25 days after sowing, Figure 3d It's a picture of romaine lettuce. As Comparative Example 2, the same cultivation was performed using a conventional urethane mat.

[0076]

[0077]Vitamin A contained in the obtained romaine lettuce and the number of common bacteria (viable bacteria number) were analyzed by the methods shown below. The results are shown in Table 3.

[0078] (1) Vitamin A: High Performance ...

Embodiment 3、4、 comparative example 3

[0090] [Example 3, 4, Comparative Example 3: Decontamination Sheet]

[0091] After soaking the Japanese paper yarn knitwear produced in the same manner as in Example 1 for 60 minutes in a liquid obtained by dispersing 5% (w / v) cyanine in 100 L of warm water at 80 to 90°C, It was washed with water, dried naturally outdoors, and colored (Example 4). A 10 cm x 14 cm uncolored Japanese paper yarn knit fabric (Example 3), a Japanese paper yarn knit fabric colored by the above-mentioned method (Example 4), and cotton colored by the same method (Comparative Example 3) were soaked in a mixture containing After a predetermined time in 1000 mL of an aqueous solution of 137Cs, water was collected and radioactivity was measured using a germanium semiconductor detector (manufactured by ORTE, GEM-35). The results are shown in Table 5. In Table 5, "blank sample" is an aqueous solution containing 137Cs.

[0092] [table 5]

[0093]

[0094] As shown in Table 5, although about 25% of 137...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com