One-dose drag reducer for fracturing and preparation method thereof

A technology of drag reducer and fracturing, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of narrow use range of drag reducer, difficulty in selection and use of drag reducer, different requirements of drag reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

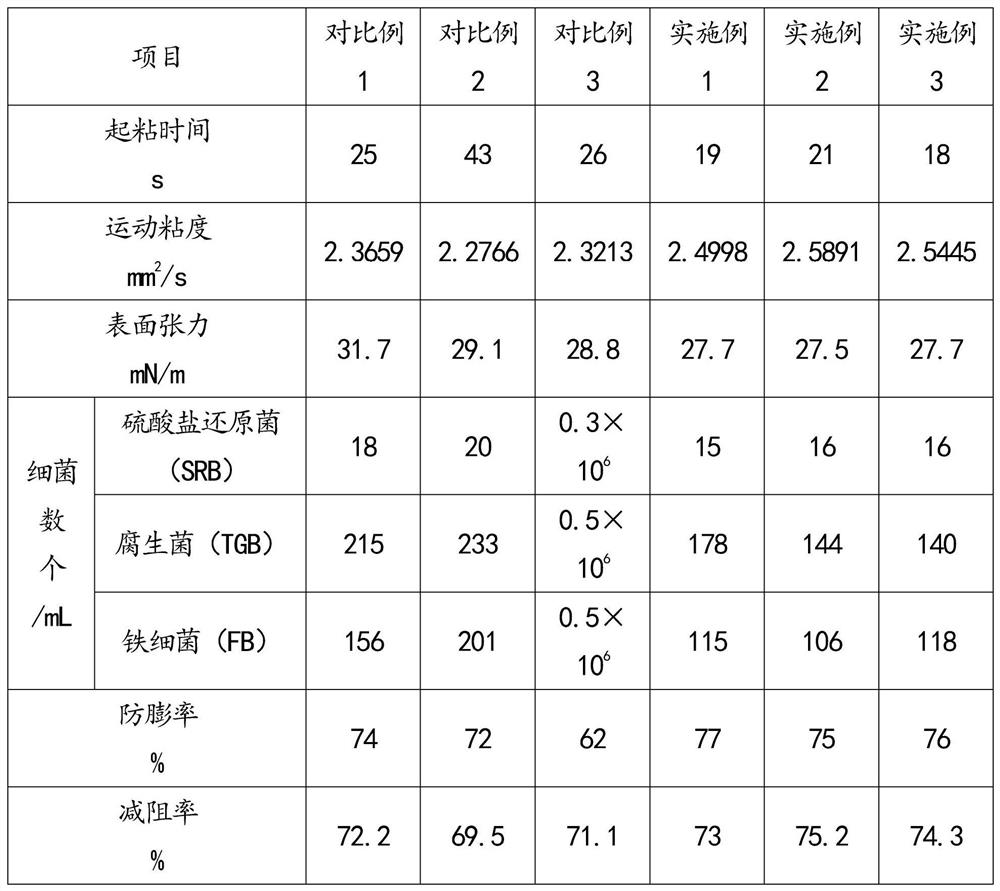

Examples

Embodiment 1

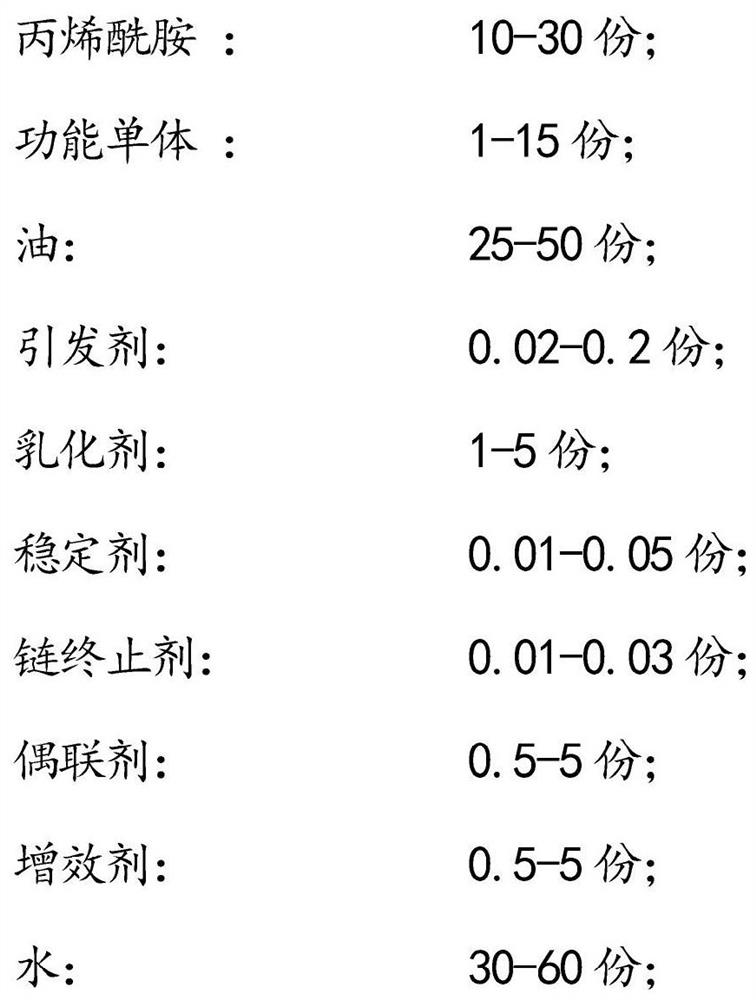

[0026] The preparation method of a one-dose fracturing drag reducer comprises the following steps:

[0027] (1) Preparation of oil phase: weigh 25 parts of 3# white oil, 2 parts of KH590 coupling agent, 0.05 parts of urea, 0.5 parts of glutaraldehyde, 0.5 parts of potassium chloride, 1.5 parts of Op-4 and 1.5 parts of Span 80 and mix Add it into reaction vessel A and stir evenly at a stirring speed of 500r / min to obtain intermediate A;

[0028] (2) Preparation of water phase: Weigh 45 parts of water, 20 parts of acrylamide, 10 parts of acrylic acid, and 5 parts of methyl acrylate, mix them into reaction vessel B, stir until completely dissolved, then transfer to the reaction vessel with mechanical stirring In container C, turn on the mechanical stirring and feed nitrogen gas for 20 minutes, remove the air in the reaction system, then stop the mechanical stirring and stop feeding nitrogen gas, and slowly add intermediate A dropwise to the reaction container C with mechanical st...

Embodiment 2

[0032] The preparation method of a one-dose fracturing drag reducer comprises the following steps:

[0033] (1) Preparation of oil phase: Weigh 10 parts of 3# white oil, 10 parts of 15# white oil, 2 parts of KH570 coupling agent, 0.05 part of lauric acid, 0.5 part of glutaraldehyde, 0.5 part of potassium chloride, 1.5 part of Op -4 and 1.5 parts of Span 80 were mixed and added to reaction vessel A and stirred evenly at a stirring speed of 600r / min to obtain intermediate A;

[0034] (2) Preparation of water phase: Weigh 40 parts of water, 20 parts of acrylamide, 10 parts of acrylic acid, and 5 parts of methyl acrylate, mix them into reaction vessel B, stir until completely dissolved, then transfer to the reaction vessel with mechanical stirring In container C, turn on the mechanical stirring and feed nitrogen gas for 20 minutes, remove the air in the reaction system, then stop the mechanical stirring and stop feeding nitrogen gas, and slowly add intermediate A dropwise to the r...

Embodiment 3

[0038] The preparation method of a one-dose fracturing drag reducer comprises the following steps:

[0039] (1) Preparation of oil phase: weigh 15 parts of methyl oleate, 1 part of KH550 coupling agent, 0.05 part of lauric acid, 1 part of glutaraldehyde, 1 part of potassium chloride, 1 part of Op-4 and 1 part of Span 80 Mix and add to reaction vessel A and stir evenly at a stirring speed of 600r / min to obtain intermediate A;

[0040] (2) Preparation of water phase: Weigh 40 parts of water, 20 parts of acrylamide, 10 parts of acrylic acid, and 5 parts of methyl acrylate, mix them into reaction vessel B, stir until completely dissolved, then transfer to the reaction vessel with mechanical stirring In container C, turn on the mechanical stirring and feed nitrogen gas for 20 minutes, remove the air in the reaction system, then stop the mechanical stirring and stop feeding nitrogen gas, and slowly add intermediate A dropwise to the reaction container C with mechanical stirring. 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com