Anti-swelling clay stabilizer for water injection in low-permeability reservoirs and preparation method thereof

A clay stabilizer and low-permeability technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve problems such as difficulty in using low-permeability oil fields, and achieve the effects of good compatibility, simple synthesis process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: anti-swelling clay stabilizer E 1 and its preparation method

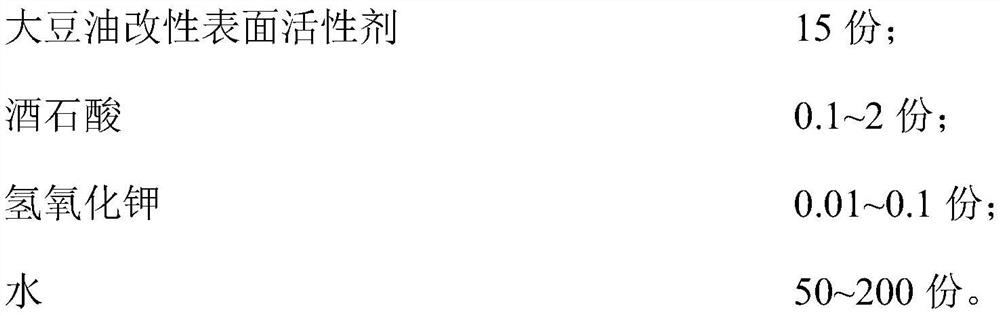

[0032] (1) Anti-swelling clay stabilizer E 1 The composition and components are as follows:

[0033]

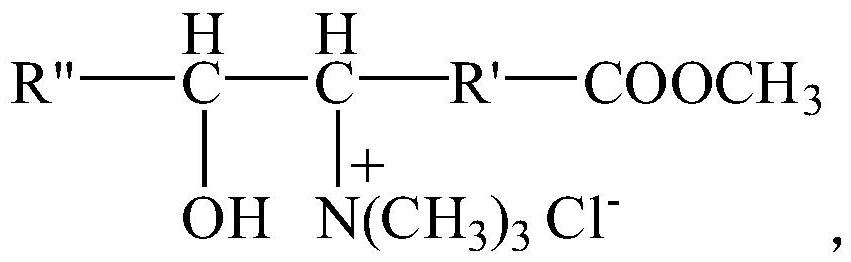

[0034] According to existing literature, the synthetic route of described soybean oil modified surfactant is as follows:

[0035]

[0036]

[0037] Among them: R″ is C n h 2n+1 , 0≤n≤15; R' is C m h 2m+1 , 0≤m≤15.

[0038] (2) Anti-swelling clay stabilizer E 1 The preparation method is as follows:

[0039] ①Put 50 parts of water in a beaker and heat it in a constant temperature water bath at 40°C; add 0.1 part of tartaric acid at a stirring rate of 300 rpm, and continue stirring for 10 minutes to obtain a mixed solution;

[0040] ② Adjust the temperature of the above mixed solution to 25°C, slowly add 0.01 part of potassium hydroxide at a stirring rate of 200rpm, and continue to stir for 30 minutes after it is completely added; then raise the temperature to 60°C, and keep the...

Embodiment 2

[0042] Embodiment 2: anti-swelling clay stabilizer E 2 and its preparation method

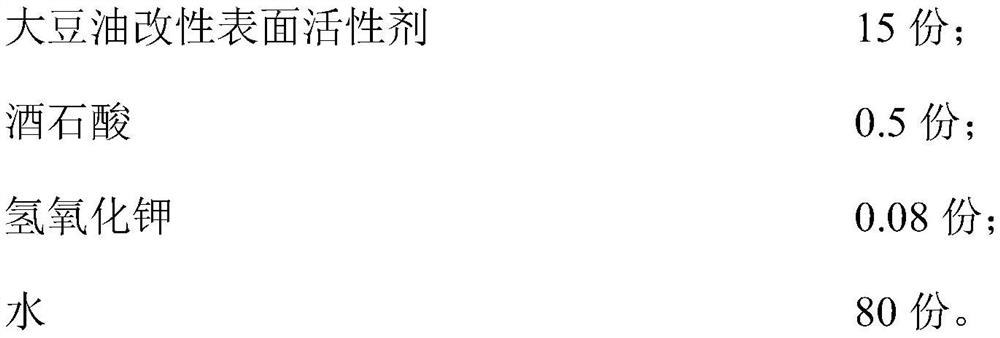

[0043] (1) Anti-swelling clay stabilizer E 2 The composition and components are as follows:

[0044]

[0045] According to existing literature, the synthetic route of described soybean oil modified surfactant is as follows:

[0046]

[0047]

[0048] Among them: R″ is C n h 2n+1 , 0≤n≤15; R' is C m h 2m+1 , 0≤m≤15.

[0049] (2) Anti-swelling clay stabilizer E 2 The preparation method is as follows:

[0050] ①Put 80 parts of water in a beaker and heat it in a constant temperature water bath at 45°C; add 0.5 parts of tartaric acid at a stirring rate of 320 rpm, and continue stirring for 12 minutes to obtain a mixed solution;

[0051] ② Adjust the temperature of the above mixed solution to 28°C, slowly add 0.08 parts of potassium hydroxide at a stirring rate of 250rpm, and continue stirring for 40 minutes after it is completely added; then raise the temperature to 65°C, and keep ...

Embodiment 3

[0053] Embodiment 3: anti-swelling clay stabilizer E 3 and its preparation method

[0054] (1) Anti-swelling clay stabilizer E 3 The composition and components are as follows:

[0055]

[0056] According to existing literature, the synthetic route of described soybean oil modified surfactant is as follows:

[0057]

[0058]

[0059] Among them: R″ is C n h 2n+1 , 0≤n≤15; R' is C m h 2m+1 , 0≤m≤15.

[0060] (2) Anti-swelling clay stabilizer E 3 The preparation method is as follows:

[0061] ①Put 150 parts of water in a beaker and heat it in a constant temperature water bath at 55°C; add 1.0 part of tartaric acid at a stirring rate of 330 rpm, and continue stirring for 15 minutes to obtain a mixed solution;

[0062] ② Adjust the temperature of the above mixed solution to 26°C, slowly add 0.05 parts of potassium hydroxide at a stirring rate of 220rpm, and continue stirring for 45 minutes after the addition is complete; then raise the temperature to 70°C, and kee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com