Self-adaptive machining method for manipulator

A processing method and manipulator technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of not considering sensor value deviation, difficulty in ensuring stability, and affecting processing accuracy, so as to avoid sensor value deviation and improve processing stability performance, to achieve the effect of stable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention will be further described below in conjunction with specific embodiments:

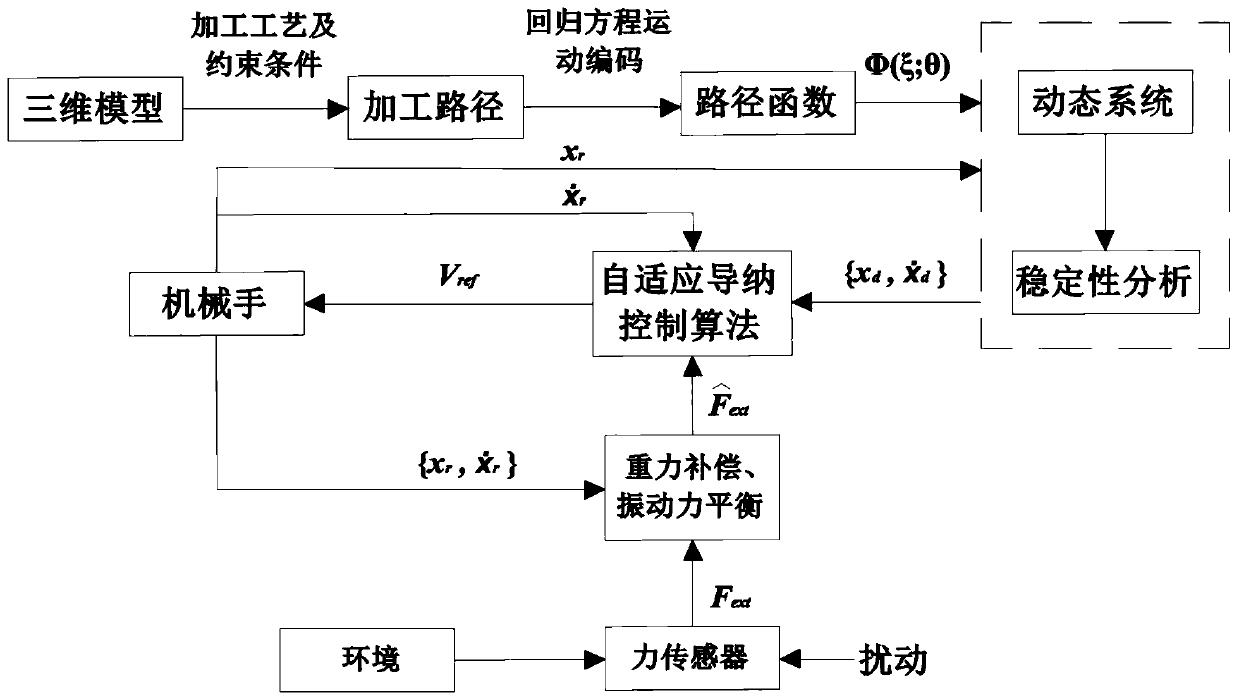

[0036] This embodiment provides a manipulator adaptive processing method, which is also a manipulator processing control method. The manipulator used in this processing method can be a conventional manipulator. In this embodiment, a multi-joint series manipulator is used as an example for illustration. The type of grinding can be conventional cutting, grinding or polishing. In this embodiment, grinding is taken as an example for illustration.

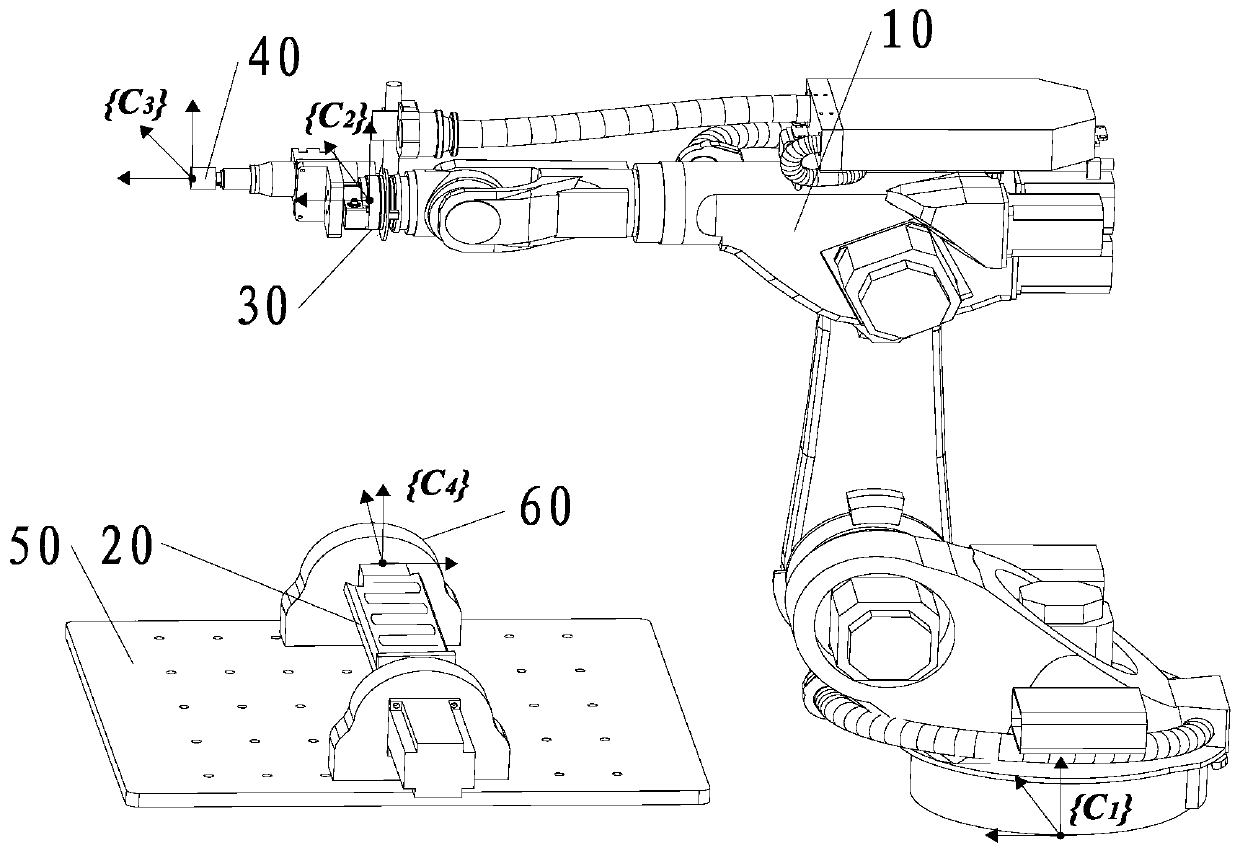

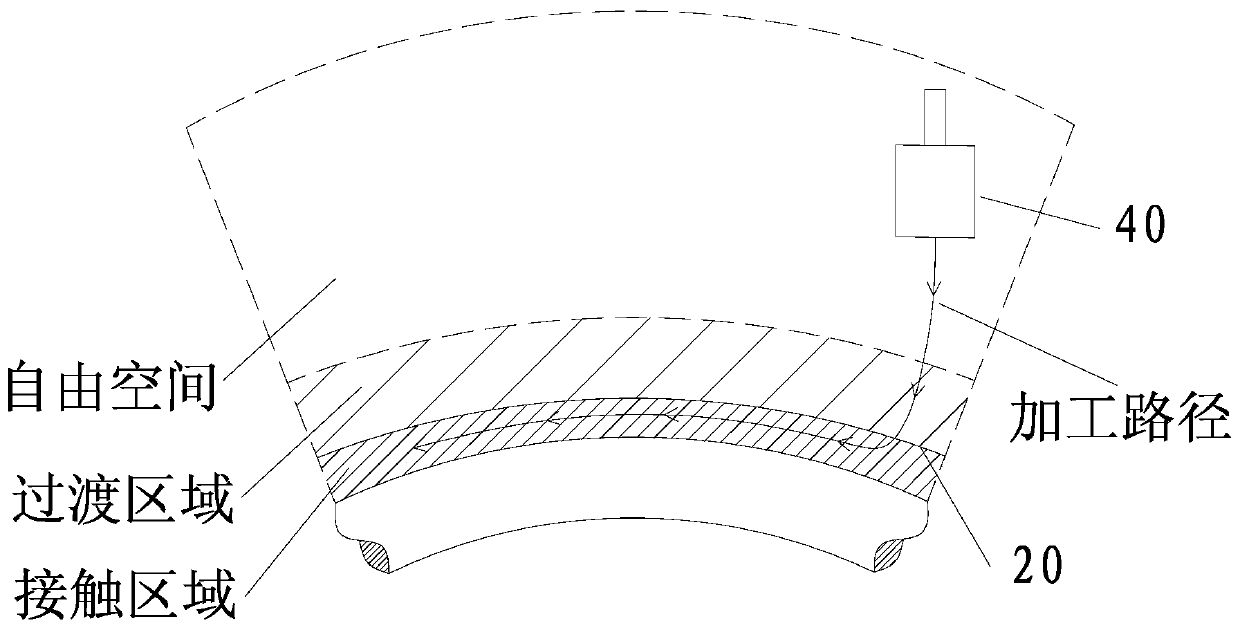

[0037] Such as figure 1 As shown, the end of the manipulator 10 is equipped with a sensor 30 for collecting the contact force between the manipulator 10 and the workpiece 20. The sensor 30 is a conventional force sensor or torque sensor, and the processing tool is installed on the sensor 30. In this embodiment , the processing tool is a grinding head 40, and the grinding head 40 is installed on the sensor 30 through a rotating shaft. Next ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com