Purification method of magnesium hydroxide and method for recovery of magnesium hydroxide from magnesium air batteries and preparation of magnesium oxide therefrom

A magnesium hydroxide, air battery technology, applied in magnesium hydroxide, magnesium oxide, chemical instruments and methods, etc., can solve the problems of limited increase of calcium-silicon ratio and inability to ensure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Conduct discharge experiments with self-made magnesium-air batteries, and convert electrodes made of pure magnesium into magnesium hydroxide;

[0042] Magnesium-air battery setup:

[0043] Effective area of the air electrode (that is, the area that is effectively facing the magnesium electrode): 20m*25cm; Catalyst: 20% platinum carbon, purchased from Johnson Matthey; Catalyst loading: 0.1mg / cm 2 ; Magnesium electrode size: 20cm*26cm*0.5cm; Magnesium purity: ≥99.90%, the electrolyte is NaCl aqueous solution, the concentration is 10wt.%;

[0044] The above-mentioned magnesium-air battery was discharged with a constant current of 3A until the magnesium electrode was consumed to the point that it could not continue to discharge. Take out all the white solid residue, wash it with deionized water three times, 300mL each time, dry it at 80°C to a white powder, and weigh 900g for use.

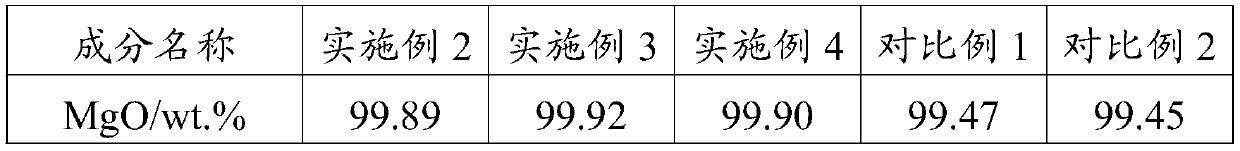

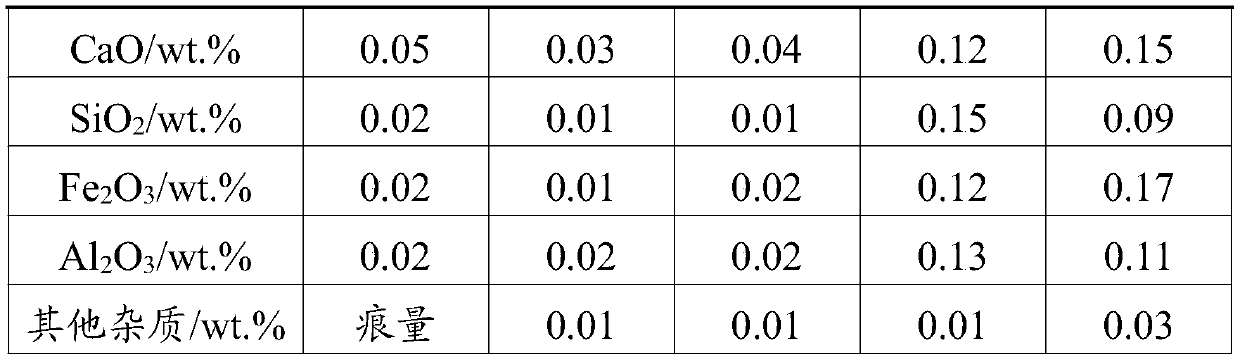

Embodiment 2

[0046] Weigh out 100g from the white powder prepared in Example 1, use 50mL concentration of 1wt.% edetate disodium magnesium aqueous solution to rinse, then rinse three times with deionized water, each time 100mL, rinse The washed white powder is placed in a muffle furnace and calcined at 1000°C for 6 hours to obtain magnesium oxide.

Embodiment 3

[0048] The method of Example 2 was adopted, except that the aqueous solution of magnesium disodium edetate was replaced by an aqueous solution of magnesium citrate with a concentration of 1 wt.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com