Temperature sensor based on grapheme-film-modified biconical micro-nano optical fiber coupler

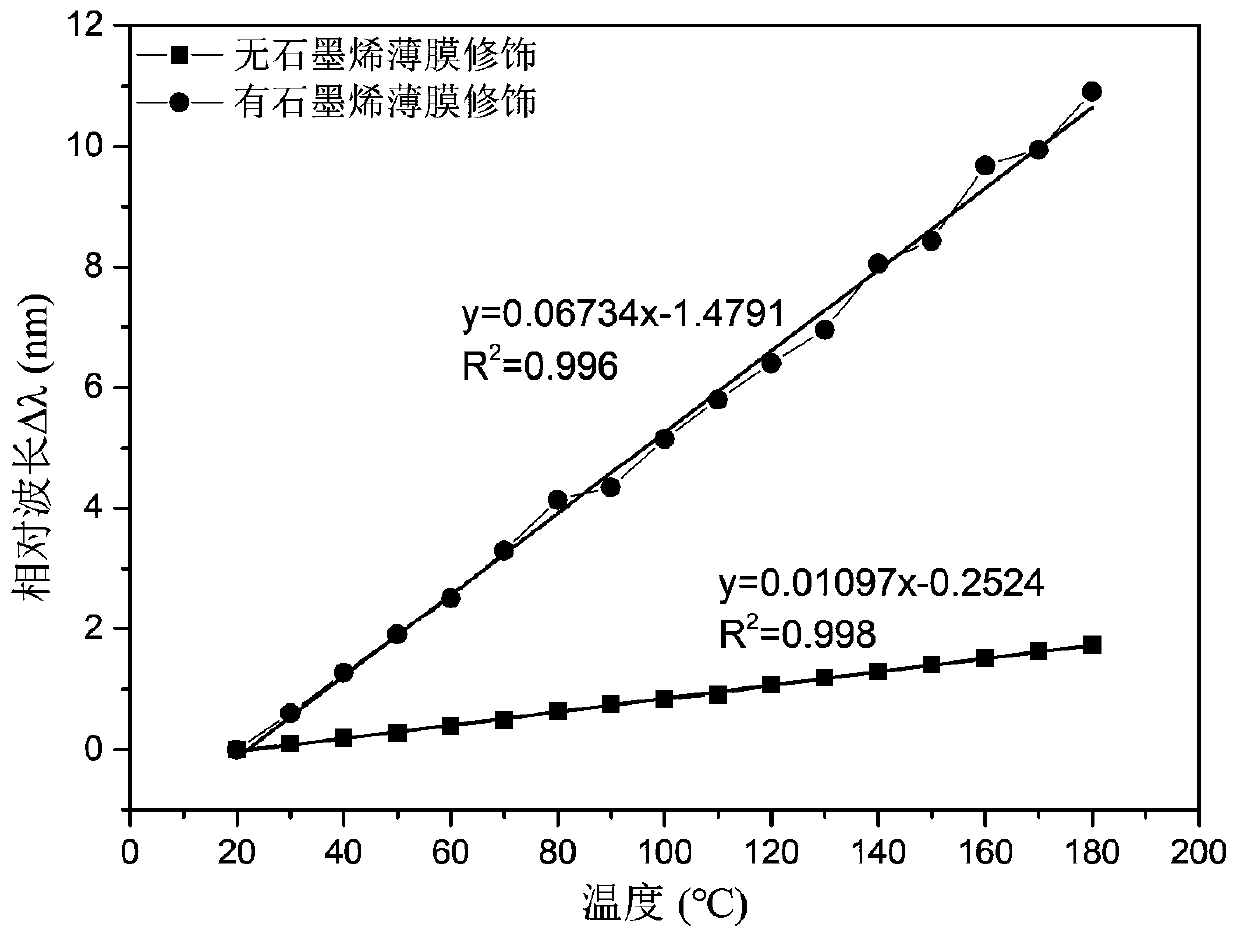

A graphene film, temperature sensor technology, applied in the coupling of optical waveguides, thermometers with physical/chemical changes, thermometers, etc., can solve the problem of difficult to meet high-performance sensing requirements, extremely high light source stability requirements, and limited measurement range. It can achieve the effect of excellent stability and repeatability, strong anti-electromagnetic interference ability and fast response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

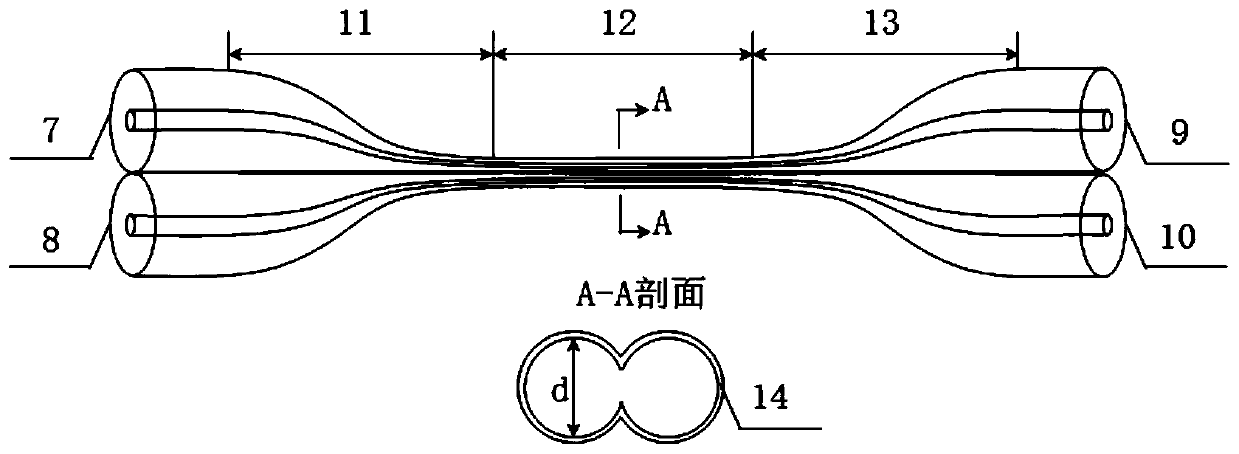

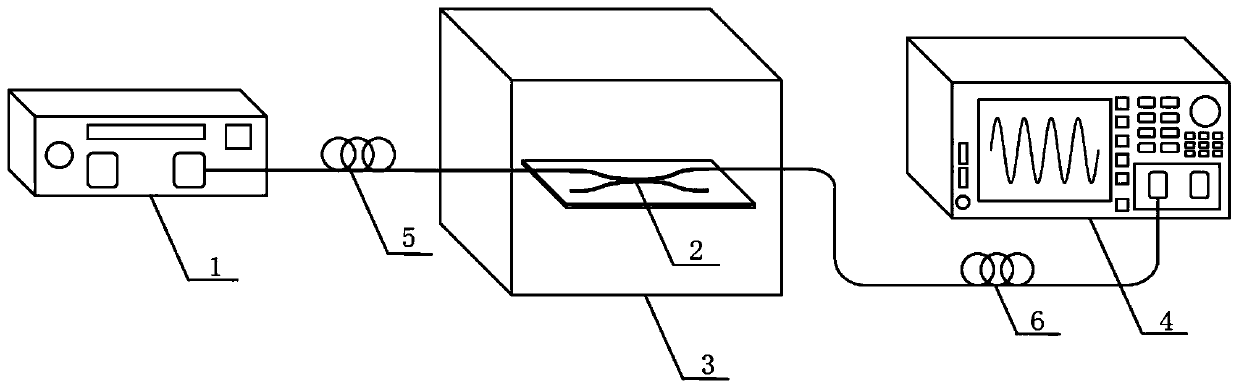

[0025] Such as figure 1 Shown is the structure diagram of the double-tapered micro-nano fiber coupler modified by graphene film. It includes two single-mode optical fibers with a diameter of 125 μm and a core diameter of 8 μm. The coating layer in the middle part is stripped and wound with each other for 3 to 4 turns. The micro-nano fiber coupler includes a lumbar homogeneous zone 12 with a constant diameter in the middle and a first transition cone 11 and a second transition cone 13 with symmetrical diameters at both ends that change exponentially, and the lumbar uniform zone 12 is coated with a single layer of graphite ene film 14; the first transition cone region 11 has two input ports 7,8, and the second transition cone region 13 has two output ports 9,10, wherein ports 7 and 9 are the same optical fiber, and ports 8 and 10 are another On...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com