Groove-shaped insulated gate bipolar transistor and fabrication method thereof

A technology of bipolar transistors and insulated gates, which is applied in the field of trench-type insulated gate bipolar transistors and its preparation, can solve the problems of increasing the off time, increasing the carrier concentration of the emitter, and deteriorating the compromise characteristics, so as to reduce the Turn-off time and turn-off loss, improvement of conduction voltage drop and turn-off loss, effect of improving trade-off relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

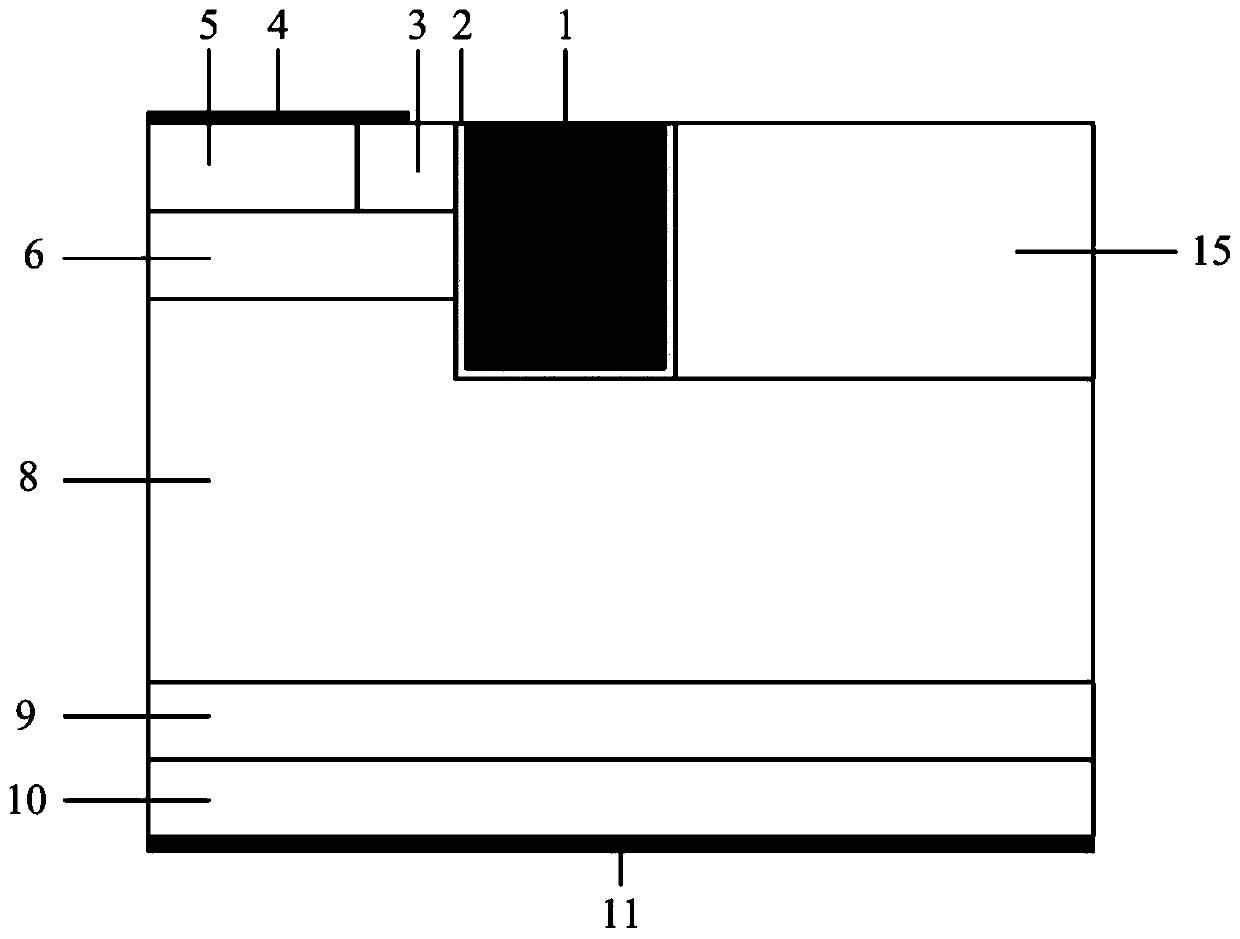

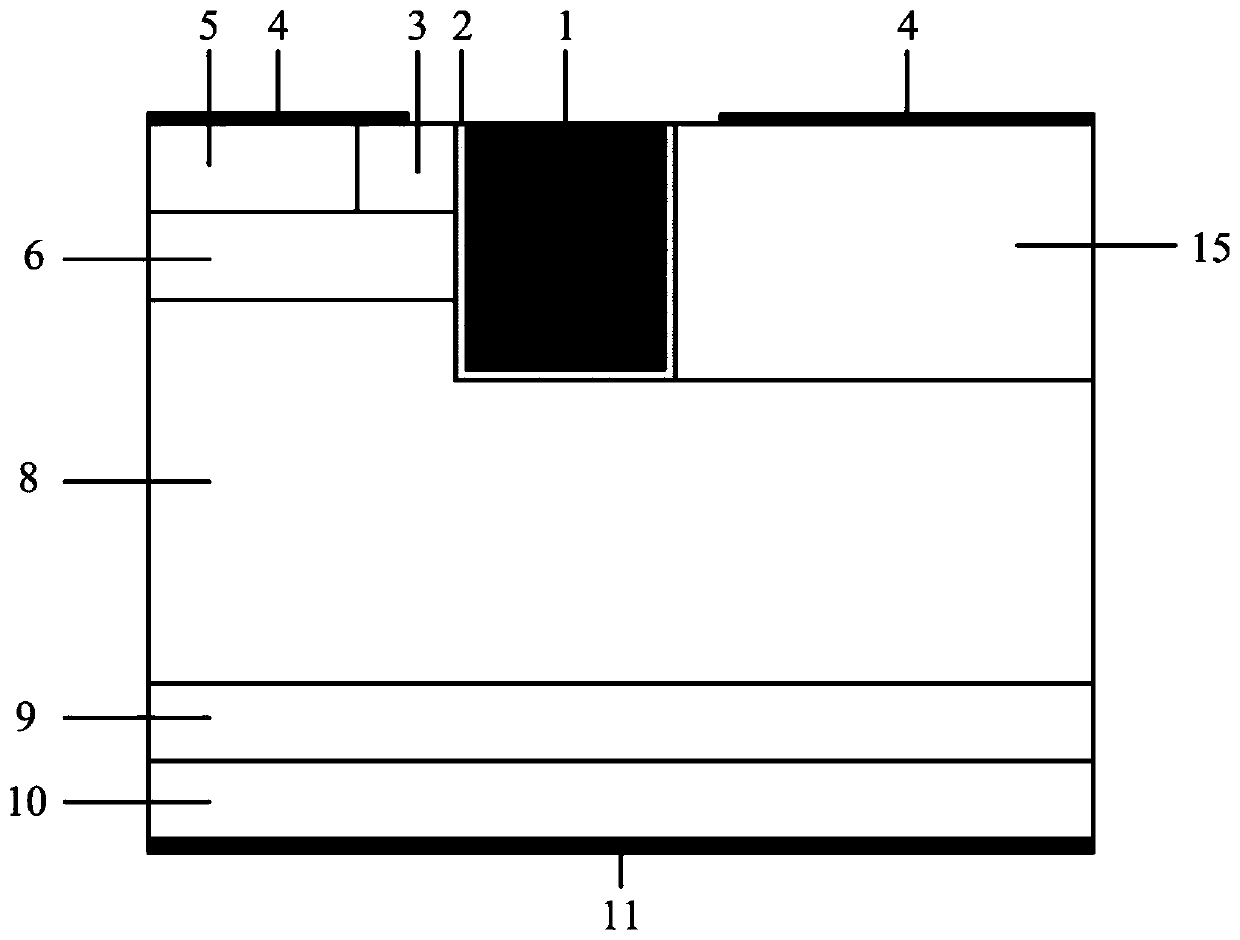

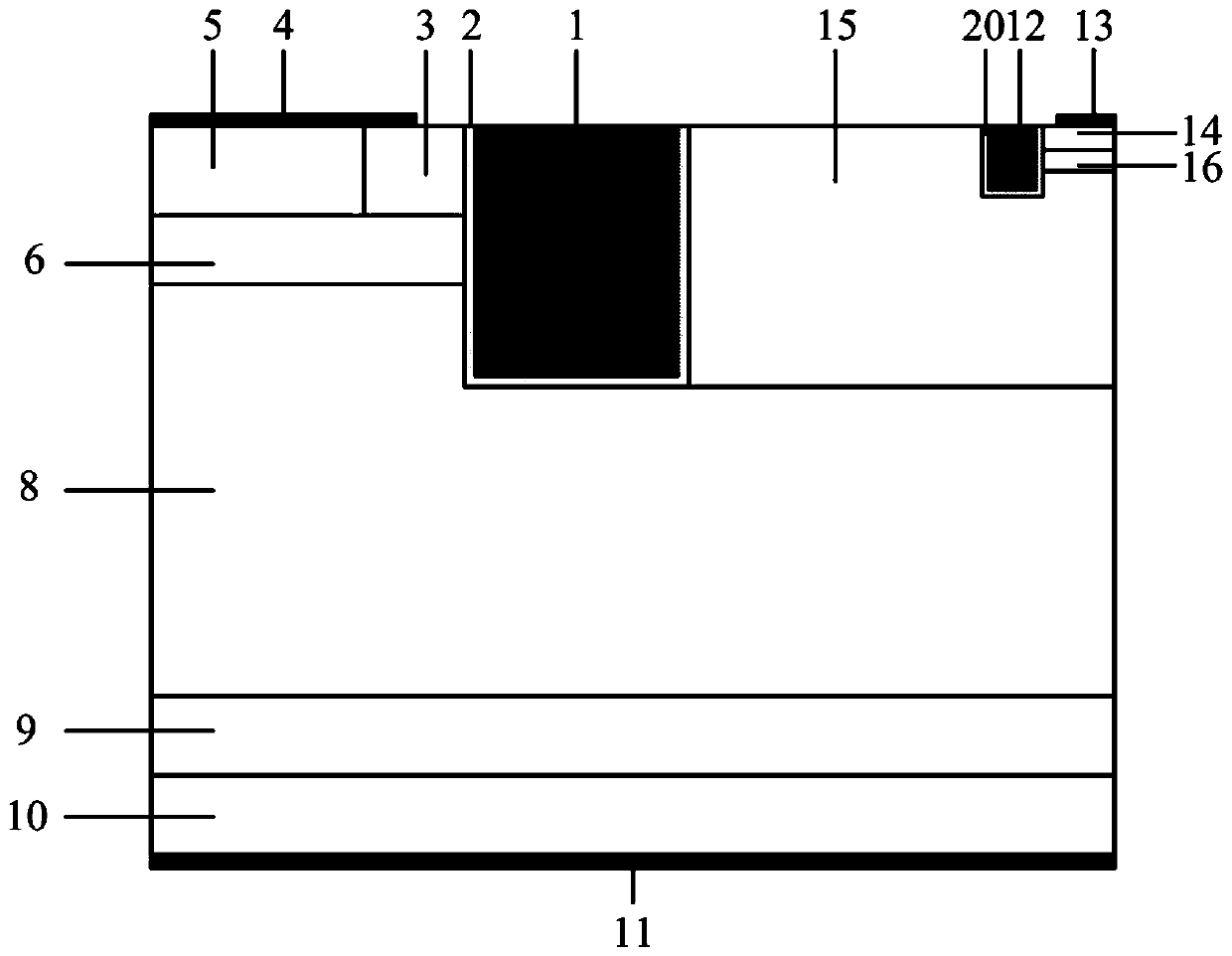

[0050] Such as image 3 As shown, the first embodiment of the present invention provides a trench-type insulated gate bipolar transistor, including: a metallized collector 11, a second conductivity type collector region 10, a first conductivity type semiconductor field stop layer 9, a first Conduction type semiconductor drift region 8, second conductivity type semiconductor base region 6, second conductivity type semiconductor emission region 5, first conductivity type semiconductor emission region 3, first trench gate structure, emitter metal 4, second conductivity type The floating region 15, the first conductivity type semiconductor base region 16, the second conductivity type semiconductor drain region 14, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com