Preparation method of Fe based suspended bed hydro-cracking catalyst

A hydrocracking and catalyst technology, which is used in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Template agent environmental pollution and other problems, to achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) 27.05 gFeCl 3 ·6H 2 O was added to 39.2 ml deionized water to prepare 2 mol / L FeCl 3 solution, heated and stirred in a water bath at 80 °C for 1 h;

[0038] (2) Prepare the NaOH solution of 6 mol / L, add the prepared NaOH solution dropwise to the FeCl prepared in step (1) 3 In the solution, reddish-brown flocs will be produced subsequently, and after the pH value of the solvent in the reddish-brown flocs is above 11.2, stop adding the NaOH solution dropwise;

[0039] (3) Add 5 g of powdered scallop powder, 2 g of isopropanol, 5 g of glacial acetic acid and 5 g of NaOH to 40 ml of deionized water and absolute ethanol (by mass ratio, deionized water: absolute ethanol=3 : 1) In the mixed solution, stir at room temperature for 3 h, then sonicate for 1 h, and finally stir in a water bath at 80 °C for 1.5 h;

[0040] (4) Add the final mixture obtained in step (3) to the reddish-brown floc prepared in step (2), stir rapidly for 1 min to form a gel, and stop stirring;

...

Embodiment 2

[0044] (1) 27.05 gFeCl 3 ·6H 2 O was added to 39.2 ml deionized water to prepare 2 mol / L FeCl 3 solution, heated and stirred in a water bath at 80 °C for 1 h;

[0045] (2) Prepare the NaOH solution of 6 mol / L, add the prepared NaOH solution dropwise to the FeCl prepared in step (1) 3 In the solution, reddish-brown flocs will be produced subsequently, and after the pH value of the solvent in the reddish-brown flocs is above 11.2, stop adding the NaOH solution dropwise;

[0046] (3) Add 10 g of powdered safflower powder, 2 g of isopropanol, 5 g of glacial acetic acid and 5 g of NaOH to 40 ml of deionized water and absolute ethanol (by mass ratio, deionized water: absolute ethanol=3 : 1) In the mixed solution, stir at room temperature for 3 h, then sonicate for 1 h, and finally stir in a water bath at 80 °C for 1.5 h;

[0047] (4) Add the final mixture obtained in step (3) to the reddish-brown floc prepared in step (2), stir rapidly for 1 min to form a gel, and stop stirring;...

Embodiment 3

[0051] (1) 27.05 gFeCl 3 ·6H 2 O was added to 39.2 ml deionized water to prepare 2 mol / L FeCl 3 solution, heated and stirred in a water bath at 80 °C for 1 h;

[0052] (2) Prepare the NaOH solution of 6 mol / L, add the prepared NaOH solution dropwise to the FeCl prepared in step (1) 3 In the solution, reddish-brown flocs will be produced subsequently, and after the pH value of the solvent in the reddish-brown flocs is above 11.2, stop adding the NaOH solution dropwise;

[0053] (3) Add 10 g of powdered safflower powder, 2 g of isopropanol, 5 g of glacial acetic acid and 5 g of NaOH to 40 ml of deionized water and absolute ethanol (by mass ratio, deionized water: absolute ethanol=3 : 1) In the mixed solution, stir at room temperature for 3 h, then sonicate for 1 h, and finally stir in a water bath at 80 °C for 1.5 h;

[0054] (4) Add the final mixture obtained in step (3) to the reddish-brown floc prepared in step (2), stir rapidly for 1 min to form a gel, and stop stirring;...

PUM

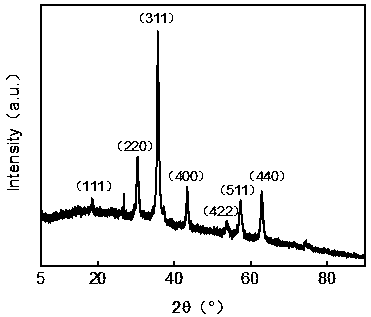

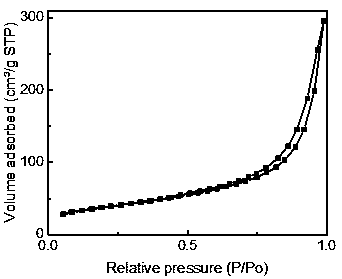

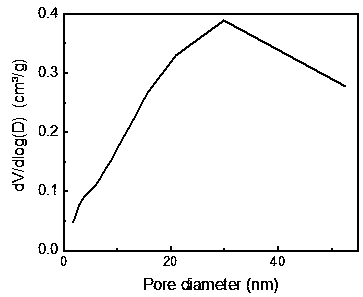

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com