Highly dispersed palladium/cobalt hydroxide catalyst and its preparation method and application

A catalyst and highly dispersed technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problems affecting the service life of the catalyst, poor ethylene selectivity, etc. Achieve high stability, high ethylene selectivity, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

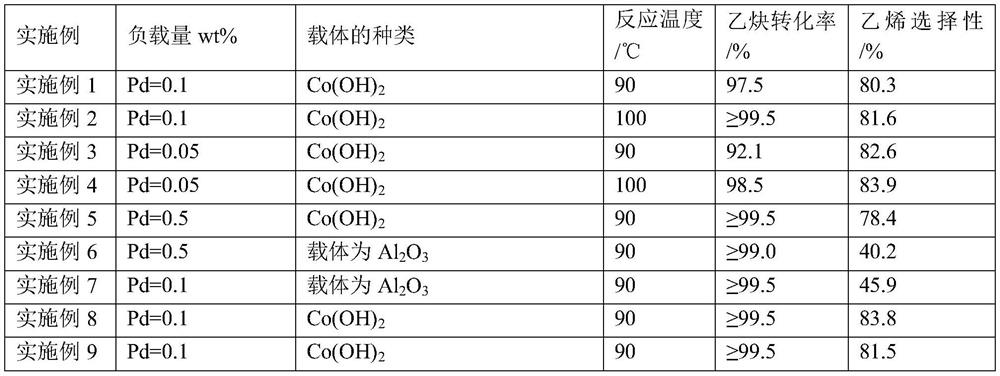

Embodiment 1-5

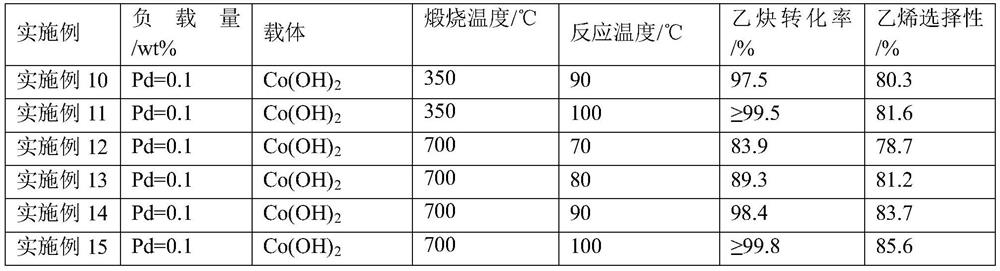

[0031] Weigh a certain amount of palladium acetate and dissolve it in concentrated hydrochloric acid, transfer it to a volumetric flask, add a certain amount of deionized water to the corresponding scale, and prepare a chloropalladium acid solution with a mass concentration of palladium of 0.001 g / mL. According to the loading capacity and its proportion listed in Table 2, mix the metered chloropalladium acid solution and a certain amount of deionized water, after stirring evenly, uniformly mix the highly dispersed Co(OH) 2 Carrier (the specific surface area is about 150-250m 2 / g) Pour into the impregnating solution, and ultrasonically disperse it evenly. Wetting the Co(OH) 2 The carrier is soaked at room temperature for 12 hours, and dried at 110°C for 12 hours. After taking out the sample, the sample is calcined at 350-700°C for 6 hours to obtain highly dispersed Pd / Co(OH) 2 catalyst.

Embodiment 4

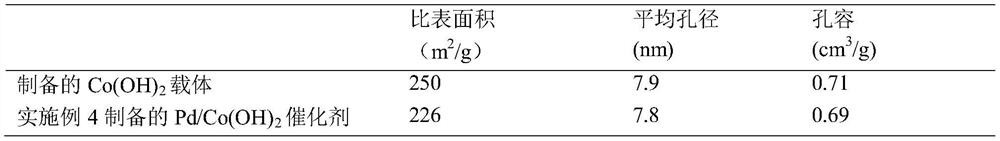

[0032] Co(OH) in Example 4 2 The comparison of the texture properties of the carrier before and after loading Pd is shown in Table 1:

[0033] Table 1 Comparison of texture properties of supports before and after loading Pd

[0034]

Embodiment 6

[0036] With reference to the operation of embodiment 5, the only difference is that the carrier is replaced by a specific surface area of 60m 2 / g of alumina to make simple Pd / Al 2 o 3 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com