A kind of antibacterial flame-retardant cellulose and its preparation and application

A technology of flame retardant cellulose and cellulose, applied in fiber processing, biochemical fiber processing, textiles and papermaking, etc., can solve problems such as building damage, national economic construction, loss of people's lives and property, and low limiting oxygen index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

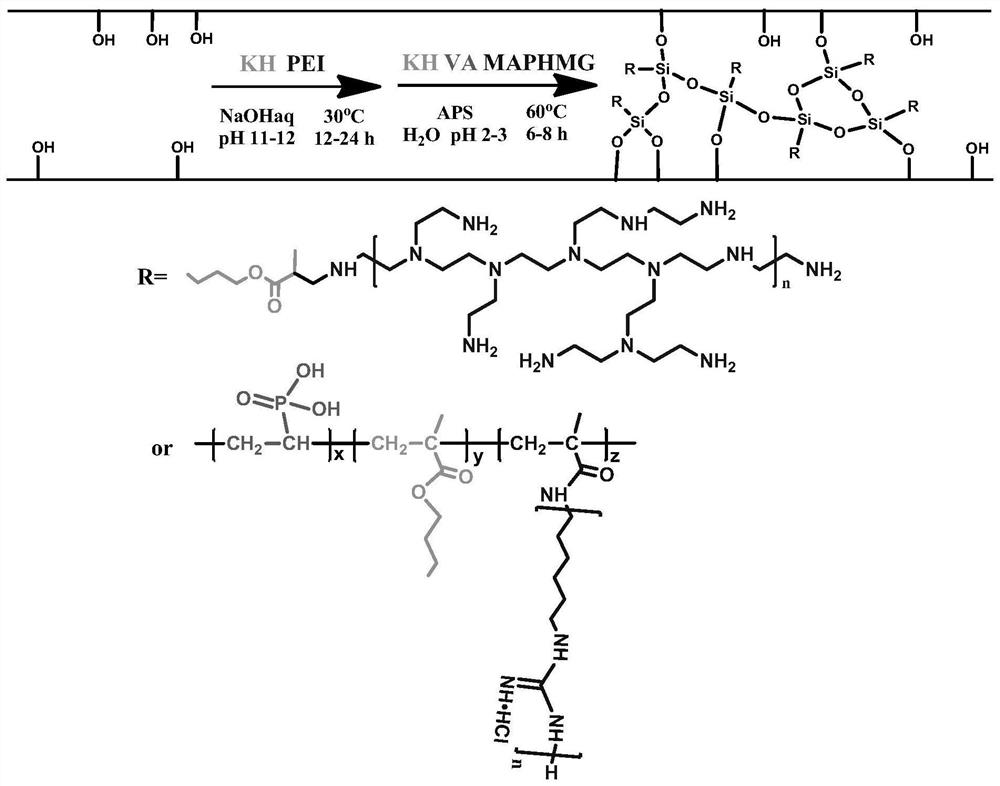

[0044] 0.2 g of NaOH was weighed and dissolved in 1 L of deionized water to prepare NaOH aq with a pH of 11.7 as a reaction solution for the Michael addition reaction.

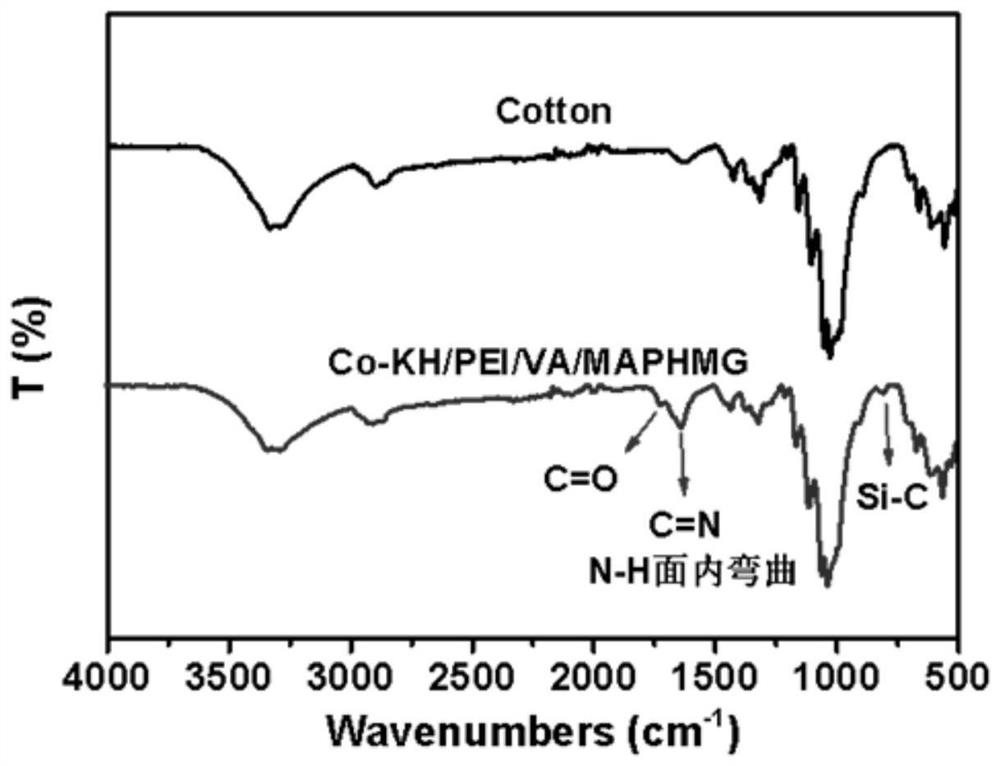

[0045] Weigh 0.1g cotton fiber and immerse in a single-necked flask with 20mL NaOH aq, then add 40wt% KH (0.04g, n(Si)=0.16mmol), 7wt% PEI (0.007g, n(N )=0.1628mmol), a one-necked flask was used as a reaction vessel and placed in a magnetic heating stirrer, and heated to 30° C. for 12 hours. After the reaction, the modified cotton fibers were ultrasonically cleaned for 10 min, and rinsed with deionized water to fully remove the substances that were not chemically grafted on the surface of the fibers. After cleaning, they were dried in a blast oven at 60°C to obtain the product (I).

[0046] The product (I) was submerged in 20 mL of deionized water, and diluted HCl was added to adjust the pH between 2-3, and then 10 wt% of KH (0.01 g, n(Si)=0.04 mmol), 20 wt % of VA ( 0.02 g, n(P) = 0.185 mmol), 5 wt% of MAPH...

Embodiment 2

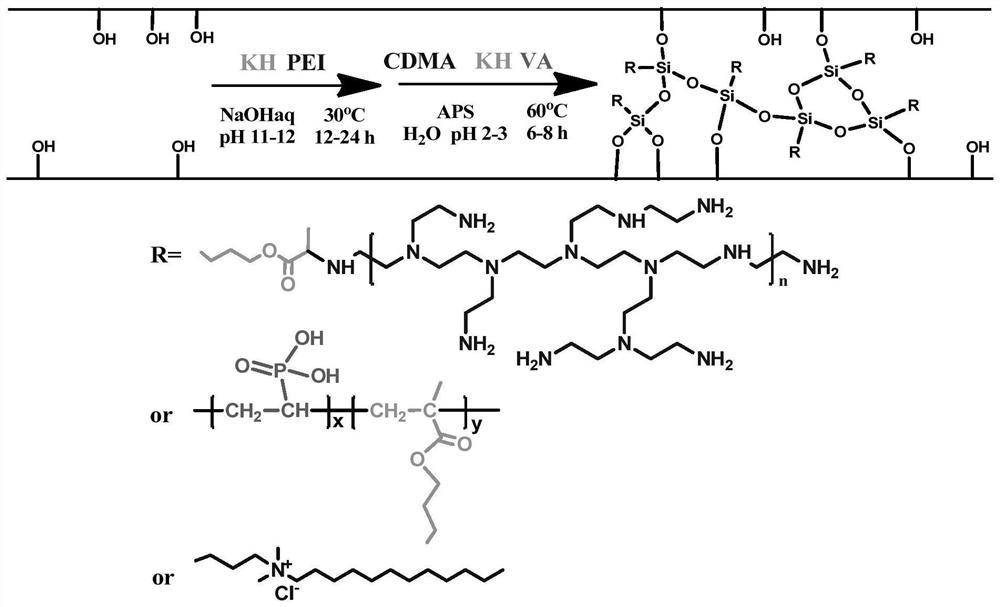

[0049] 0.2 g of NaOH was weighed and dissolved in 1 L of deionized water to prepare NaOH aq with a pH of 11.7 as a reaction solution for the Michael addition reaction.

[0050] Weigh 0.1g cotton fiber and immerse in a single-necked flask with 20mL NaOH aq, then add 40wt% KH (0.04g, n(Si)=0.16mmol), 7wt% PEI (0.007g, n(N )=0.1628mmol), a one-necked flask was used as a reaction vessel and placed in a magnetic heating stirrer, and heated to 30° C. for 12 hours. After the reaction, the modified cotton fibers were ultrasonically cleaned for 10 min, and rinsed with deionized water to fully remove the substances that were not chemically grafted on the surface of the fibers. After cleaning, they were dried in a blast oven at 60°C to obtain the product (I).

[0051] The product (I) was submerged in 20 mL of deionized water, and diluted HCl was added to adjust the pH between 2-3, and then 10 wt% of KH (0.01 g, n(Si)=0.04 mmol), 20 wt % of VA ( 0.02g, n(P)=0.185mmol), 5 wt% of CDMA (0....

Embodiment 3

[0054] 0.2 g of NaOH was weighed and dissolved in 1 L of deionized water to prepare NaOH aq with a pH of 11.7 as a reaction solution for the Michael addition reaction.

[0055] Weigh 0.1g of cellulose pulp, immerse in a single-necked flask equipped with 20mL NaOH aq, then add 40wt% KH (0.04g, n(Si)=0.16mmol), 7wt% PEI (0.007g, n(N)=0.1628mmol), a one-necked flask was used as a reaction vessel and placed in a magnetic heating stirrer, and heated to 30° C. for 18 hours. After the reaction, the modified pulp was ultrasonically cleaned for 10 minutes, rinsed with deionized water to fully remove the substances that were not chemically grafted on the surface of the cellulose pulp, and dried in a blast oven at 60°C after cleaning. The product (I) is obtained.

[0056] The product (I) was submerged in 20 mL of deionized water, and diluted HCl was added to adjust the pH between 2-3, and then 10 wt% of KH (0.01 g, n(Si)=0.04 mmol), 20 wt % of VA ( 0.02g, n(P)=0.185mmol), 5 wt% of MAPH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com