Membrane material for membrane distillation and preparation method thereof

A membrane material and membrane distillation technology, applied in the field of membrane distillation, can solve the problems of poor heat transfer of membrane materials and pollution of membrane materials, achieve high thermal conductivity and electrical conductivity, simple operation, resistance to hydrophobic organic pollutants and enhanced heat transfer The effect of improving the mass transfer function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

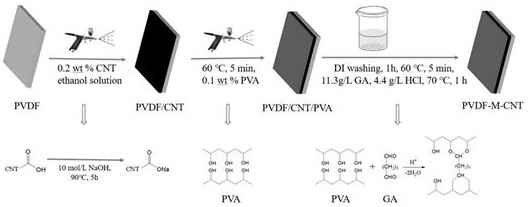

[0027] see figure 1 , a preparation method of a membrane material for membrane distillation, the specific steps are:

[0028] (1) Weigh 0.8 g of carboxylated carbon nanotubes (CNT-COOH) with a diameter of 10-20 nm and a length of 0.5-2 um and dissolve them in 500 mL of 10 mol / L NaOH solution, and stir magnetically at 90°C for 5 hours. Then centrifuge to separate the solid and liquid of CNT and NaOH solution, then wash with deionized water until the supernatant is neutral, and dry at 333 K for later use to obtain CNT-COONa for later use.

[0029] (2) An anhydrous ethanol solution with a concentration of 0.2 wt% CNT-COONa was prepared, and ultrasonicated for 40 min until the dispersion was uniform without stratification. Use a spray gun to evenly spray 0.2 wt% CNT-COONa ethanol solution on the surface of PVDF membrane (the surface in contact with the feed liquid), and the loading capacity is 0.57 mg / cm 2 , baked at 333 K for 10 min to obtain a PVDF / CNT film.

[0030] (3) Prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com