A kind of continuous production system of 4-aminoantipyrine

A technology of aminoantipyrine and production system, which is applied in the field of continuous production system of 4-aminoantipyrine, can solve the problems such as waste of manpower, low efficiency, uncontinuous production, etc., so as to avoid manpower and material resources, reduce Energy consumption, improve the effect of atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

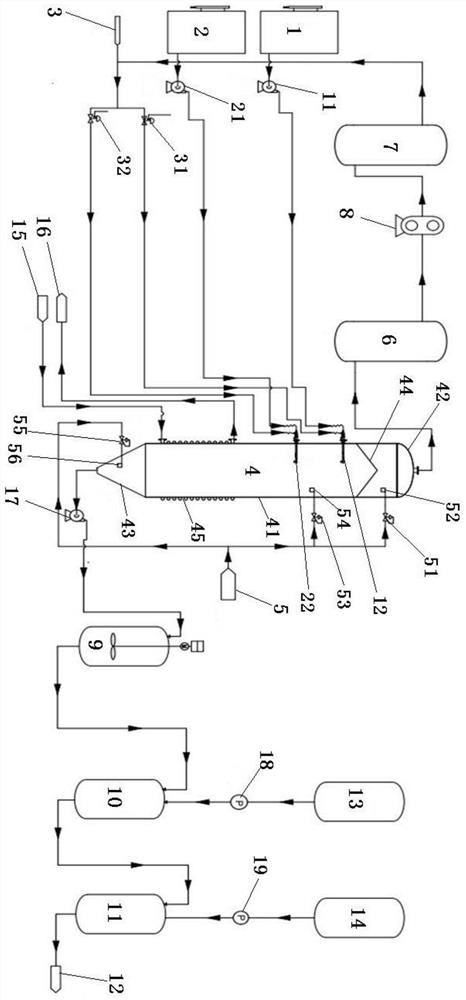

[0024] like figure 1 As shown, a continuous production system of 4-amino antipyrine comprises antipyrine sulfuric acid solution storage tank 1, sodium nitrite solution storage tank 2, N 2 Storage tank 3, impingement flow reactor 4, reducing agent storage tank 5, first buffer tank 6, second buffer tank 7, compressor 8, reduction reactor 9, hydrolysis tank 10, neutralization tank 11, product storage tank 12 , sulfuric acid storage tank 13, liquid ammonia storage tank 14, cold brine storage tank 15, cold brine recovery tank 16.

[0025] The impingement flow reactor 4 includes a straight cylindrical still body 41, an oval top cover 42 and a conical still bottom 43. The still body 41 is provided with an antipyrine sulfuric acid solution feeding port and sodium nitrite arranged up and down. The solution feeding port; the bottom of the kettle bottom 43 is provided with a discharging port, and the top of the top cover 42 is provided with an exhaust port;

[0026] The first spray gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com