Production method of ultra-high-purity triethylaluminium

A triethylaluminum, ultra-high technology, applied in the field of high-purity chemical preparation, can solve problems such as high impurity content, high silicon content, inability to remove all, and achieve high yield, less labor, and low process cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

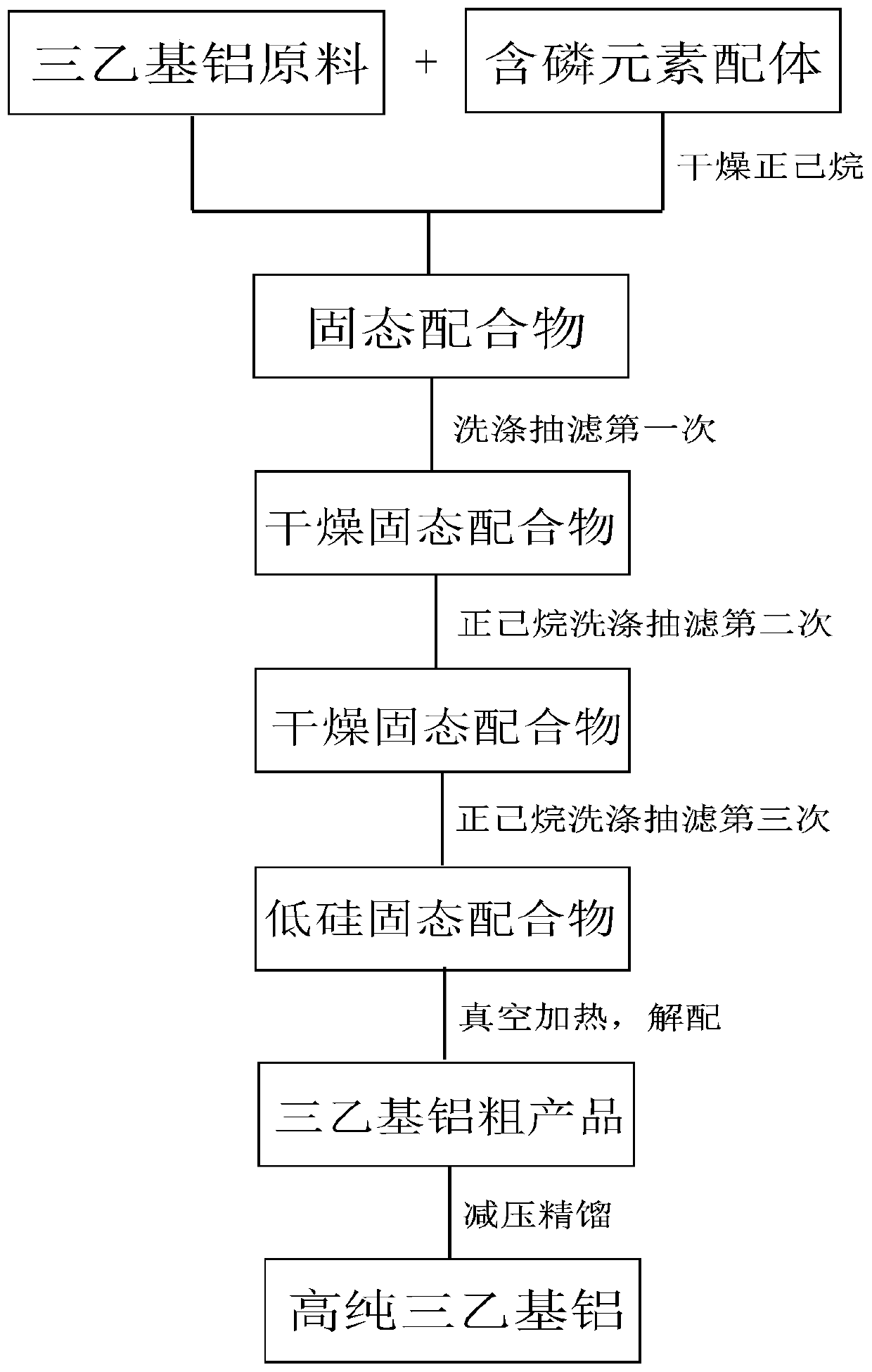

[0032] The preparation method of ultra-high-purity triethylaluminum of the present invention, concrete process step is:

[0033] 1) The raw material and the ligand form a stable solid-state complex, and the ligand is a compound containing phosphorus; in an anhydrous, oxygen-free and inert atmosphere glove box, take a ligand 1.2 times the amount of triethylaluminum and an appropriate amount of anhydrous n-hexane Put it into a round-bottomed flask, the ligand is insoluble in n-hexane to form a suspension; add the triethylaluminum raw material into the flask through a constant pressure funnel, stir and shake well, and let stand;

[0034] 2) Complex washing and filtering: outside the inert atmosphere glove box, configure a vacuum system with a cold trap. The cold trap is cooled by liquid nitrogen, and the absolute pressure of the vacuum is adjusted to 30±2KPa. slowly pour the solid complex formed by triethylaluminum and the ligand into the sand core funnel matching the suction fil...

Embodiment 1

[0040] In a 2000mL round-bottomed flask with a stirring rod, add 2.1mol of a ligand containing phosphorus, and then add 1000±50mL of dry n-hexane, stir to disperse the ligand evenly, and continue stirring.

[0041] Through a constant pressure funnel, drop 1.75mol of triethylaluminum raw material (containing 450ppm of silicon impurities) into the round bottom flask, triethylaluminum and the ligand form a solid complex, and release heat at the same time, the temperature of the kettle rises by about 10°C, and continue to stir to room temperature in the flask.

[0042] Place a clean sand core funnel on the suction filter bottle, configure a vacuum system with a cold trap outside the inert atmosphere glove box, cool the cold trap with liquid nitrogen, adjust the vacuum degree to 30±2KPa (absolute pressure), and connect it to the glove box After connecting with the suction filter bottle to build a suction filtration device, pour the suspension in the 2000mL bottle into a sand core f...

Embodiment 2

[0053] On the basis of Example 1, one n-hexane washing was reduced.

[0054] On the same device, put in the same raw materials, pour the suspension in the 2000mL bottle into a sand core funnel, perform intermittent vacuum filtration, and the filtered n-hexane falls into the suction filter bottle.

[0055] After the first suction filtration, cut off the vacuum, pour about 250±10mL of clean n-hexane into the sand core funnel to wash the solid left after suction filtration, and then suction filtration again.

[0056] Transfer away the normal hexane in the suction filter bottle, and continue to suck the solid in the sand core funnel for 30-40 minutes to make it dry.

[0057] The solids in the fritted funnel were transferred to a 2000 mL round bottom flask and weighed.

[0058] A crude product of triethylaluminum was obtained.

[0059] Put several batches of crude products into the kettle, and purify triethylaluminum by means of vacuum rectification under the vacuum degree of 0-0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com