Nano fireproof insulating thermal-insulating macromolecule material for high-speed rail vehicle body

A polymer material, high-speed rail car body technology, applied in fire-resistant coatings, coatings, etc., can solve the problems of accelerated car body combustion, casualties, poor fire insulation and thermal insulation, and achieve increased toughness, low cost, and physical and chemical mechanical properties. and the effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

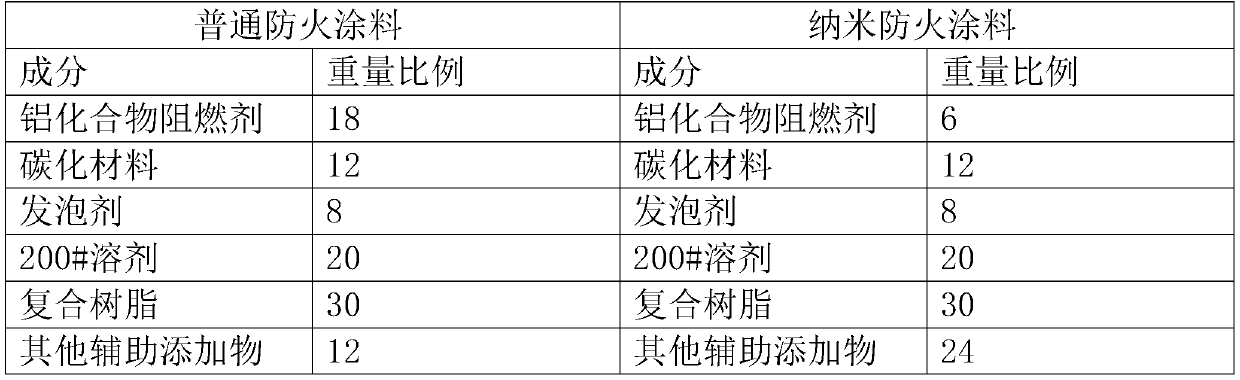

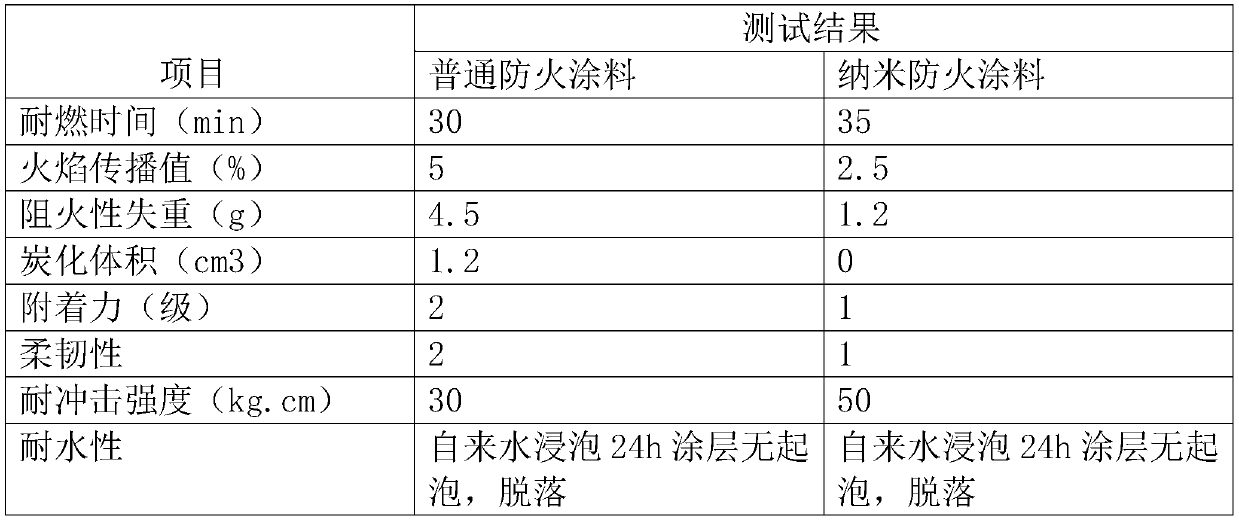

[0012] A nano fire-proof insulating heat-insulating polymer material for high-speed rail car body, including a fire-proof coating made of matrix resin, catalyst, char-forming agent and foaming agent, and also made of the following material components: nano-aluminum hydroxide, Nano silica, plasticizer, reinforcing fiber, antioxidant, graphite, film-forming aid.

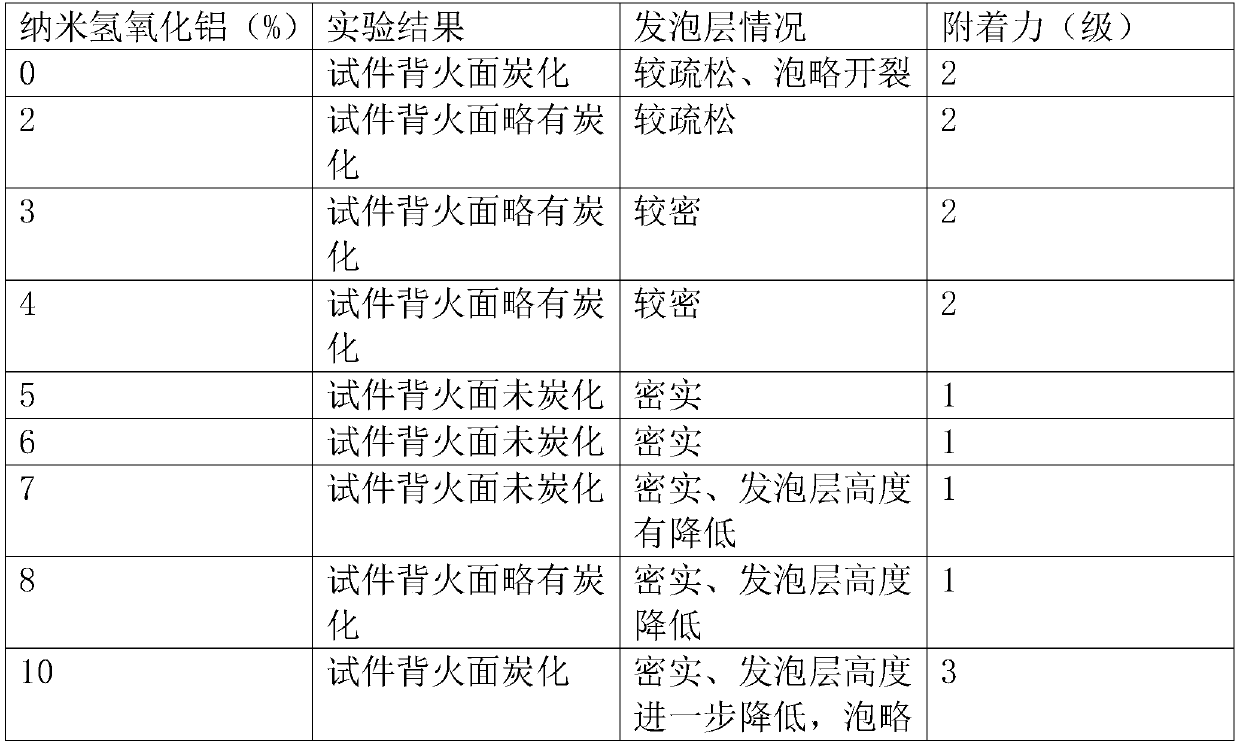

[0013] Wherein, the proportion of the nanometer aluminum hydroxide in the fireproof coating is 0-16%.

[0014] Wherein, the film-forming aid is composed of vinyl acetate, vinyl tertiary carbonate, acrylate, vinyl chloride and the like.

[0015] Wherein, the reinforcing fiber is one or more of glass fiber, mineral fiber and carbon fiber.

[0016] Wherein, the antioxidant is antioxidant 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com