A kind of stainless steel material and its preparation method and application

A stainless steel and material mixing technology, applied in the field of stainless steel tableware, can solve the problems of shortening the service life of tableware and failing to reach nickel, and achieve the effects of convenient operation, simple process, excellent corrosion resistance and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A method for preparing a stainless steel material, comprising the steps of:

[0053] ①, mixing materials:

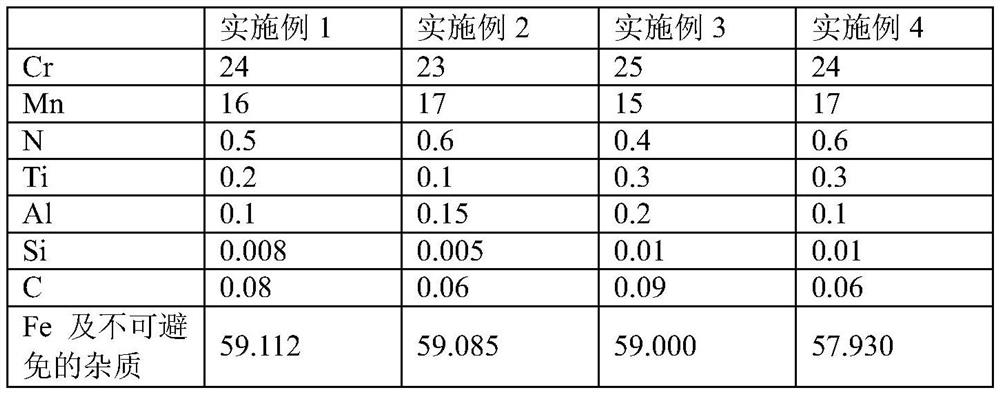

[0054] A1, take by weight percentage the Cr powder of 24kg, the Mn powder of 16kg, the Ti powder of 0.2kg, the Al powder of 0.1kg, the Si powder of 0.008kg, the C powder of 0.08kg and the Fe powder of 59.112kg and mix, obtain mixed powder;

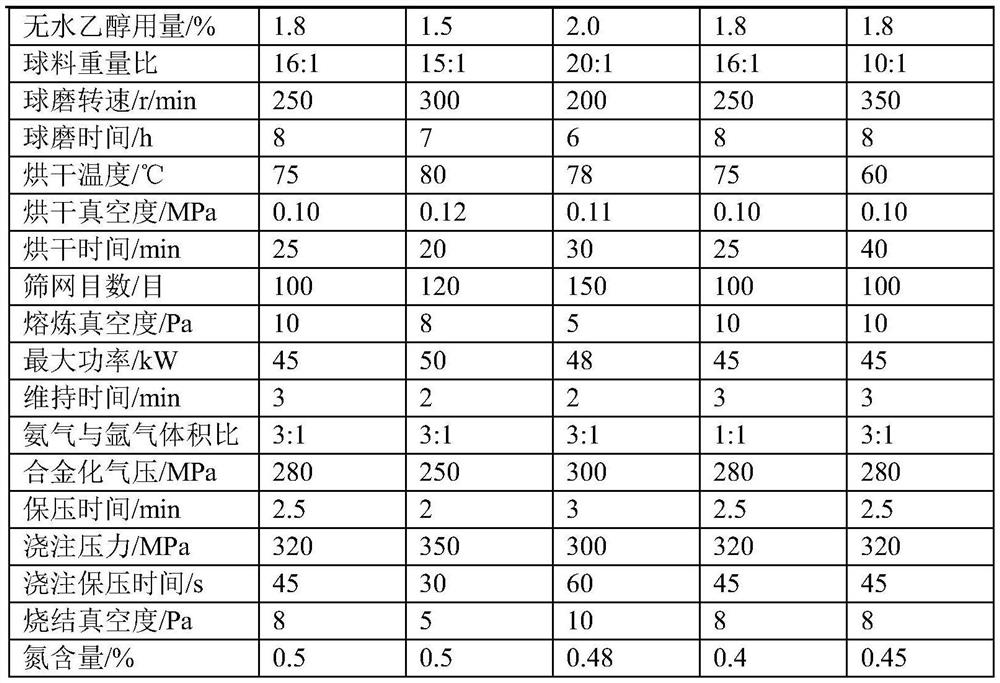

[0055] B1. The mixed powder is wet-milled under the protection of argon. The wet-milling process is as follows: put the mixed powder into a ball mill tank, add absolute ethanol accounting for 1.8% of the weight of the mixed powder, vacuumize the ball mill tank and fill it with argon Gas, the ball to material weight ratio is 16:1, the ball milling speed is 250r / min, and the ball milling time is 8h;

[0056] C1. Dry the wet-milled mixed powder with a rotary evaporator at a drying temperature of 75°C and a vacuum of 0.1 MPa. After drying for 25 minutes, pulverize it and pass it through a 100-mesh sieve to obtain an alloy powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com