High-melting-point fatty acid methyl ester or ethyl ester oil supply system

A fatty acid methyl ester and oil supply system technology, which is applied in the charging system, fuel heat treatment device, liquid fuel feeder, etc., can solve the influence that hinders the performance of fatty acid methyl ester or ethyl ester internal combustion engine. Problems such as poor liquidity, to achieve the effect of continuous circulating supply and simple system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

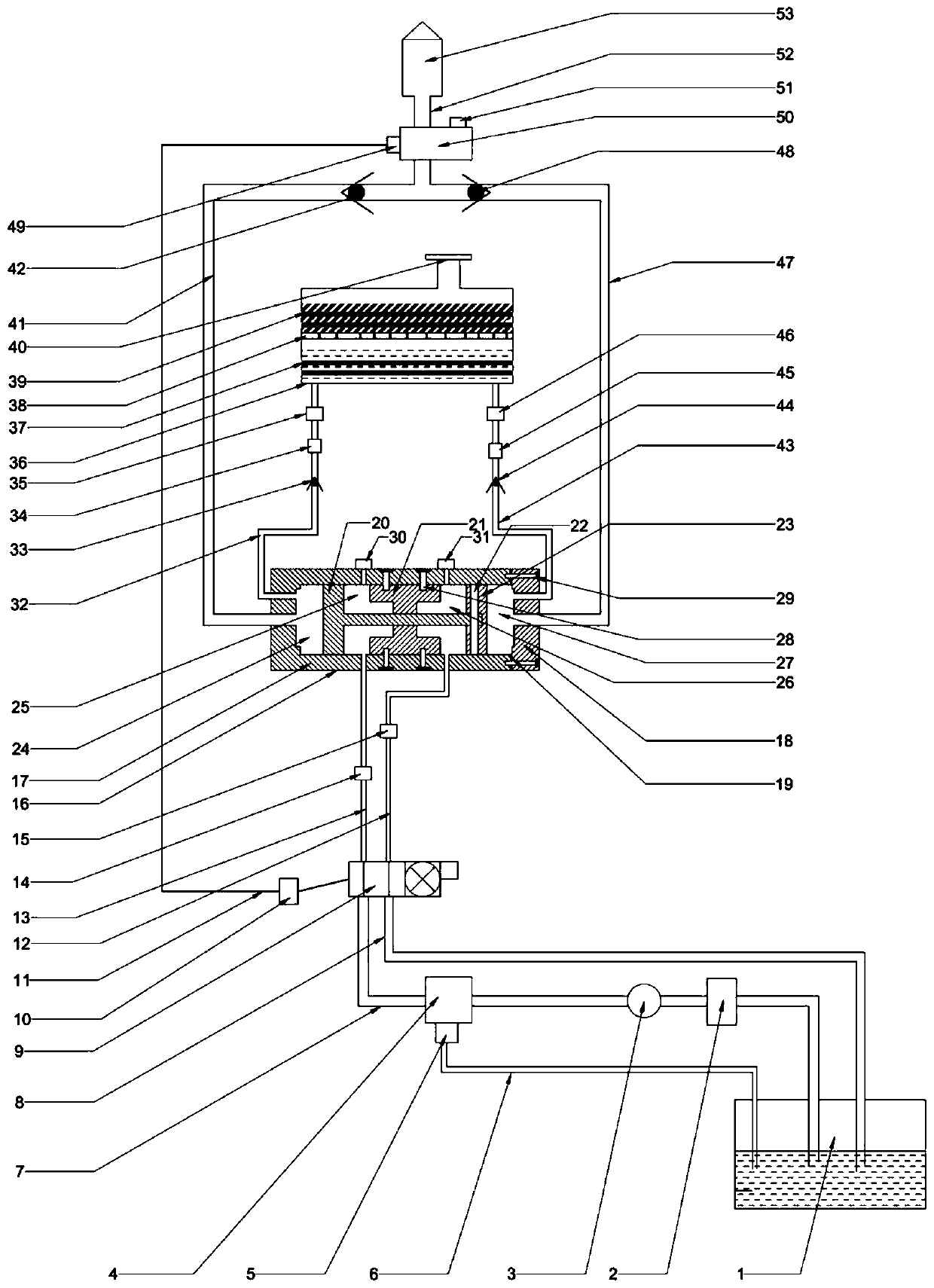

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

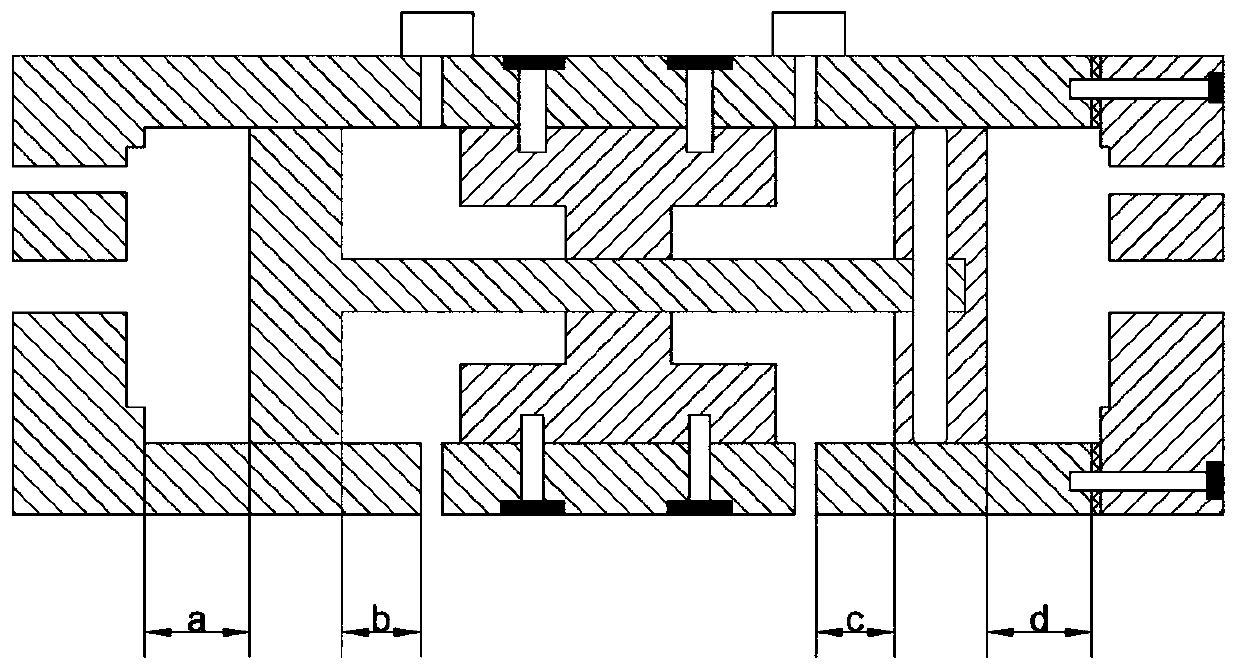

[0017] like figure 1 and figure 2 As shown, in the present invention, earlier the T-type piston 20 is passed through the round hole in the middle of the partition block 21, the T-type piston rod and the round hole are clearance fit, and the T-type piston rod can move freely left and right in the round hole; then , Install the T-shaped piston rod with the piston pin 22 in the pin hole of the piston 23, and the four parts form an assembly. The assembly composed of four parts is put into the hydraulic cylinder block 17 from the right side, and the hydraulic cylinder block 17 is provided with a first exhaust device 30 and a second exhaust device 31 for exhausting. The partition block 21 is fixed on the hydraulic cylinder block 17 by using partition block bolts 28 (two rows, 8 in each row, evenly distributed along the circumference of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com