Preparation method and application of a zinc-based metal-organic framework material and its iron-nitrogen co-doped carbon-based oxygen reduction electrocatalyst

A technology of organic framework and electrocatalyst, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of less attention in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of zinc-based metal-organic frameworks (Zn-TTPA):

[0041] The ligand TTPA-4 (13.4 mg, 0.03 mmol), terephthalic acid (10.0 mg, 0.06 mmol), zinc nitrate hexahydrate (17.8 mg, 0.06 mmol) were dissolved in 10 mL of DMF and deionized water (V:V =1:1) mixed solvent, placed in a hydrothermal still of tetrafluoroethylene and stirred evenly, heated to 100°C for reaction for 50 hours, slowly lowered to 15°C, collected the resulting crystals, and the crystals were prepared with a solvent (N,N-di Methylformamide, water, ethanol) were washed successively, and dried at room temperature to obtain a zinc-based metal organic framework material. The yield is about 65%.

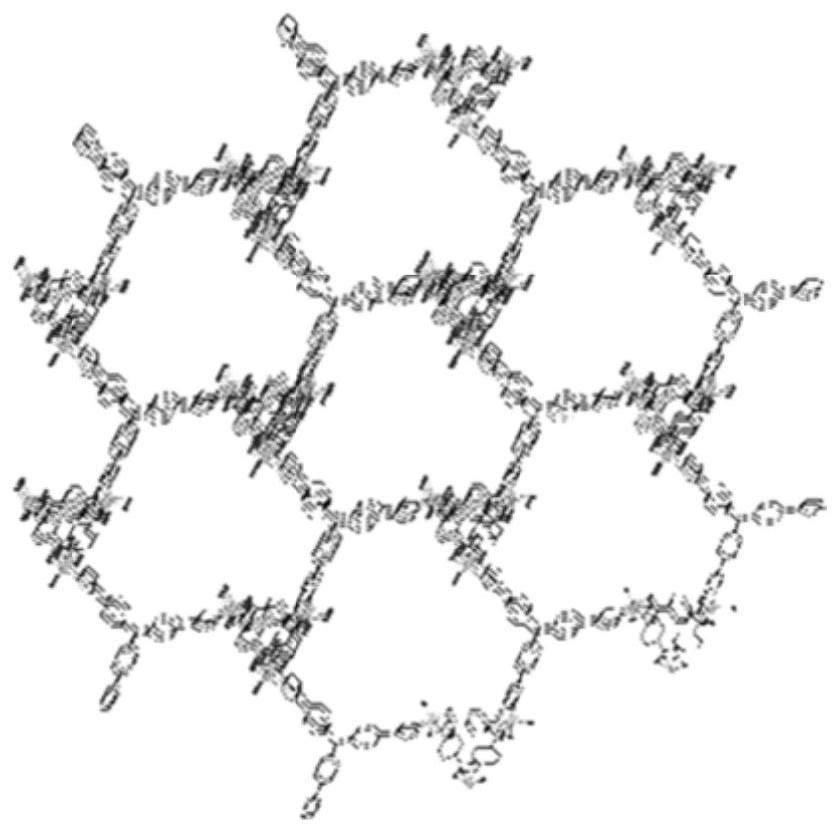

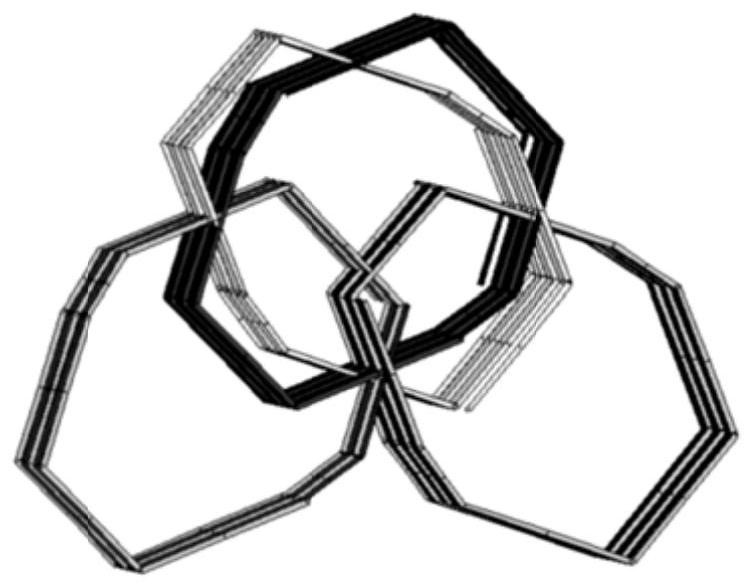

[0042] figure 1 It is a structural diagram of the zinc-based metal organic framework material Zn-TTPA obtained in Example 1 of the present invention observed along the c-axis direction. In Zn-TTPA, observed along the c-axis direction, a quasi-hexagonal structure is formed in the Zn-TTPA framework. shaped ...

Embodiment 2

[0046] Step 1. Preparation of precursor Fe-Zn-TTPA:

[0047] The ligand TTPA-4 (13.4 mg, 0.03 mmol), terephthalic acid (10.0 mg, 0.06 mmol), zinc nitrate hexahydrate (17.8 mg, 0.06 mmol), ferric nitrate nonahydrate (1.01 mg, 0.0025 mmol) were added 10mL of DMF and deionized water (V:V=1:1) mixed solvent, heated to 100°C with stirring, stirred for 72 hours, slowly lowered to 15°C, filtered to obtain a powdery solid with a yield of about 67% .

[0048] Step 2. Preparation of iron-nitrogen co-doped carbon material

[0049] The powdered solid precursor Fe-Zn-TTPA material was put into a tube furnace, heated to 950°C at 5°C / min in a nitrogen atmosphere, maintained at this temperature for 2h, cooled to room temperature at 5°C per minute, An iron-nitrogen co-doped carbon-based oxygen reduction electrocatalyst was obtained.

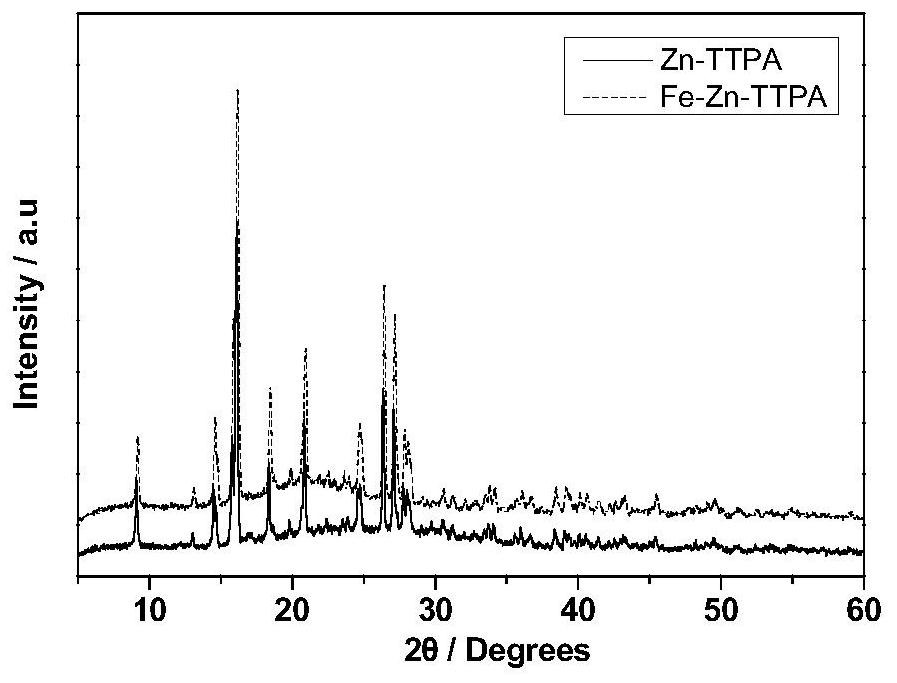

[0050] image 3 are the XRD patterns of the zinc-based metal-organic framework material Zn-TTPA and the carbonized precursor Fe-Zn-TTPA obtained in Examples ...

Embodiment 3

[0059] Step 1. Preparation of precursor Fe-Zn-TTPA:

[0060] The ligand TTPA-4 (17.9 mg, 0.04 mmol), terephthalic acid (11.7 mg, 0.07 mmol), zinc nitrate hexahydrate (20.8 mg, 0.07 mmol), ferric nitrate nonahydrate (1.21 mg, 0.003 mmol) were added 20mL of DMF and deionized water (V:V=1:1) mixed solvent, heated to 95°C with stirring, stirred for 45 hours, slowly lowered to 30°C, filtered to obtain a powdery solid with a yield of about 64% .

[0061] Step 2. Preparation of iron-nitrogen co-doped carbon material

[0062] The powdered solid precursor Fe-Zn-TTPA material was put into a tube furnace, heated to 1100°C at 10°C / min in an argon atmosphere, kept at this temperature for 2h, and cooled to room temperature at 10°C per minute , to obtain iron-nitrogen co-doped carbon-based oxygen reduction electrocatalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com