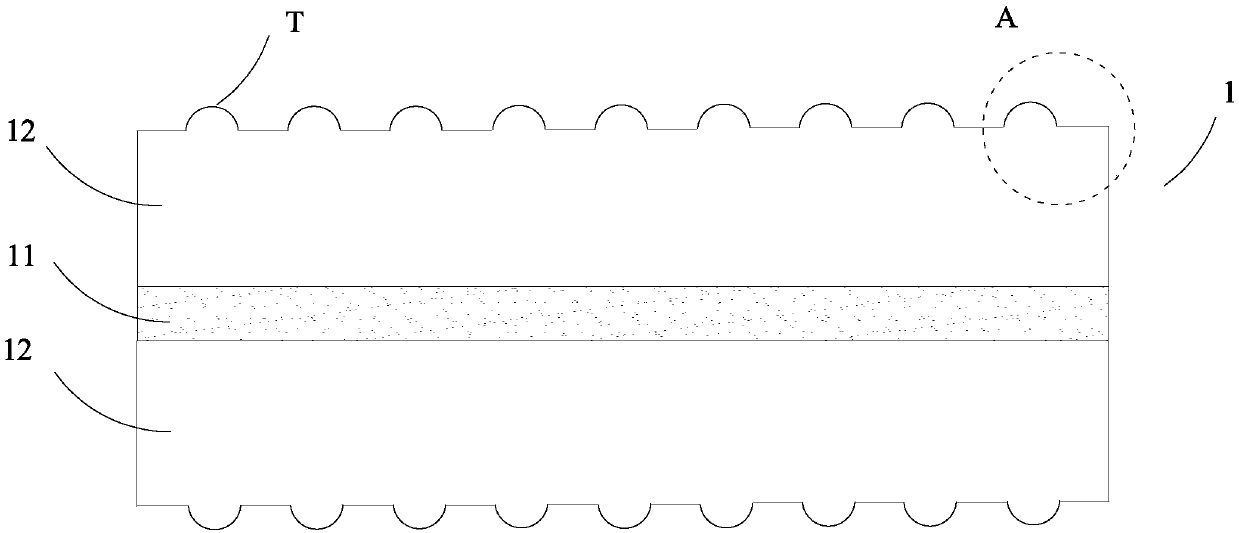

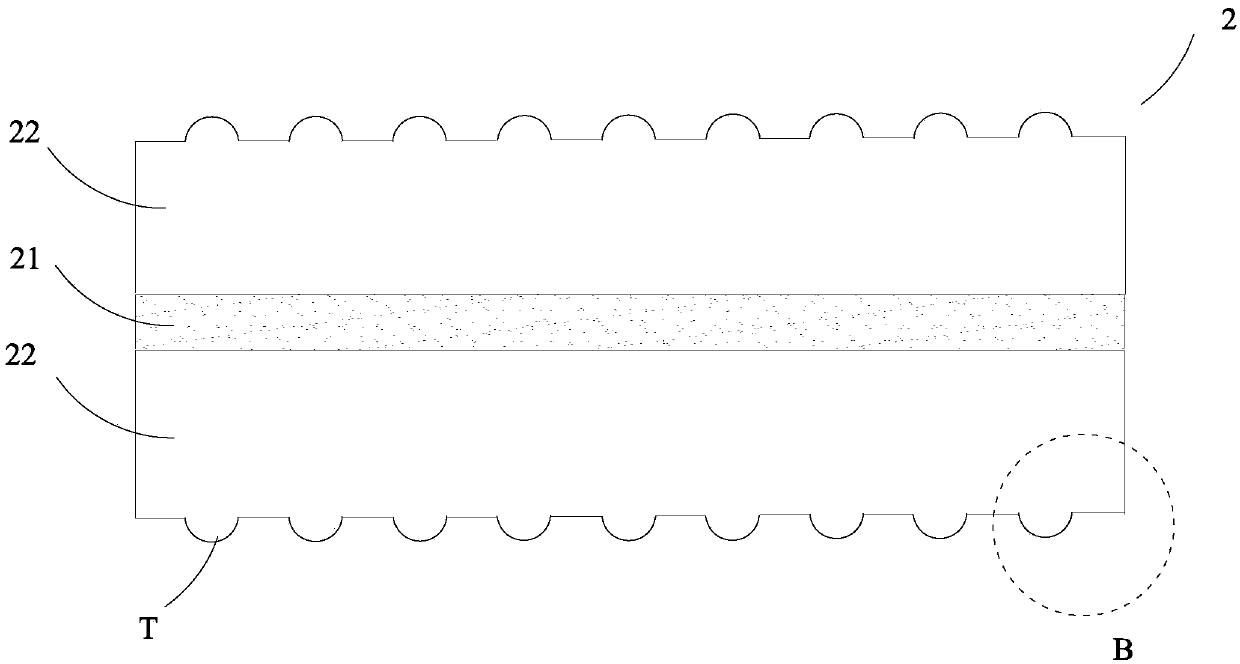

Battery and preparation method thereof

A technology for batteries and batteries, applied in the field of batteries and their preparation, can solve the problems of difficult assembly process and difficulty in ensuring the consistency of the gap between batteries and batteries, and achieve the effects of high safety, reduced production costs, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Next, the preparation method of the battery according to the second aspect of the present invention is described, which is used to prepare the battery described in the first aspect of the present invention, comprising the steps of:

[0055](1) Coating the positive electrode slurry comprising the positive electrode active material on the positive electrode current collector, drying and cold pressing to obtain the positive electrode sheet, coating the negative electrode slurry comprising the negative electrode active material on the negative electrode current collector, drying, cold pressing After pressing, the negative electrode sheet is obtained, wherein the initial thickness of the positive electrode diaphragm in the positive electrode sheet is H 1 , the initial thickness of the negative electrode diaphragm in the negative electrode sheet is H 2 ;

[0056] (2) Assemble the positive pole piece, negative pole piece, separator, and electrolyte prepared in step (1) into t...

Embodiment 1

[0062] (1) Preparation of pole piece

[0063] Carbon coated LiFePO 4 (The thickness of the carbon coating layer is 6nm, LiFePO 4 It is a primary particle structure with an average particle size of 120nm) as the positive electrode active material, acetylene black as the conductive agent, polyvinylidene fluoride as the binder, and N-methylpyrrolidone as the solvent. Stir and mix the above raw materials to form a positive electrode Slurry, wherein the weight ratio of the positive electrode active material, conductive agent, and binder is 94:4:2; then the positive electrode slurry is evenly coated on the upper and lower surfaces of the positive electrode current collector aluminum foil, and dried at 85 ° C Afterwards, it is cold pressed, and then cut to form positive electrode sheets of predetermined size.

[0064] Artificial graphite (non-acicular coke secondary particles, graphitization degree of 94%) is used as the negative electrode active material, acetylene black is used a...

Embodiment 2

[0072] The preparation process of the battery is the same as in Example 1, the difference is that:

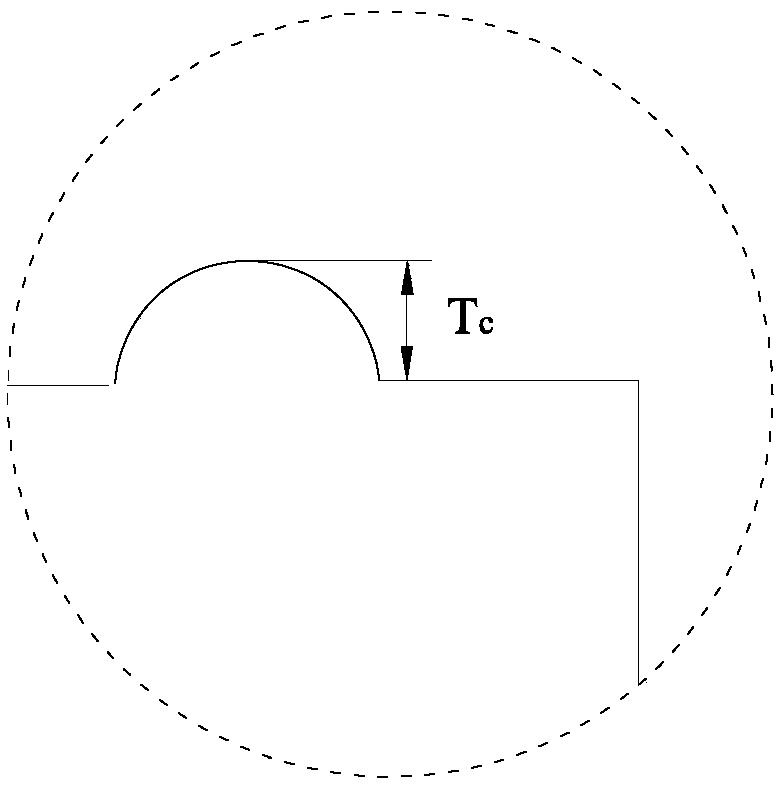

[0073] The height of the protrusions on the surface of the positive electrode membrane was 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com