supercritical co 2 Method for Fluid Recovery of Waste Lithium-ion Battery Electrolyte

A lithium-ion battery, supercritical technology, applied in ion exchange, battery recovery, ion exchange regeneration and other directions, can solve the problems of difficult separation, environmental pollution of organic solvents, etc., to achieve large adsorption capacity, good extraction effect, high extraction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

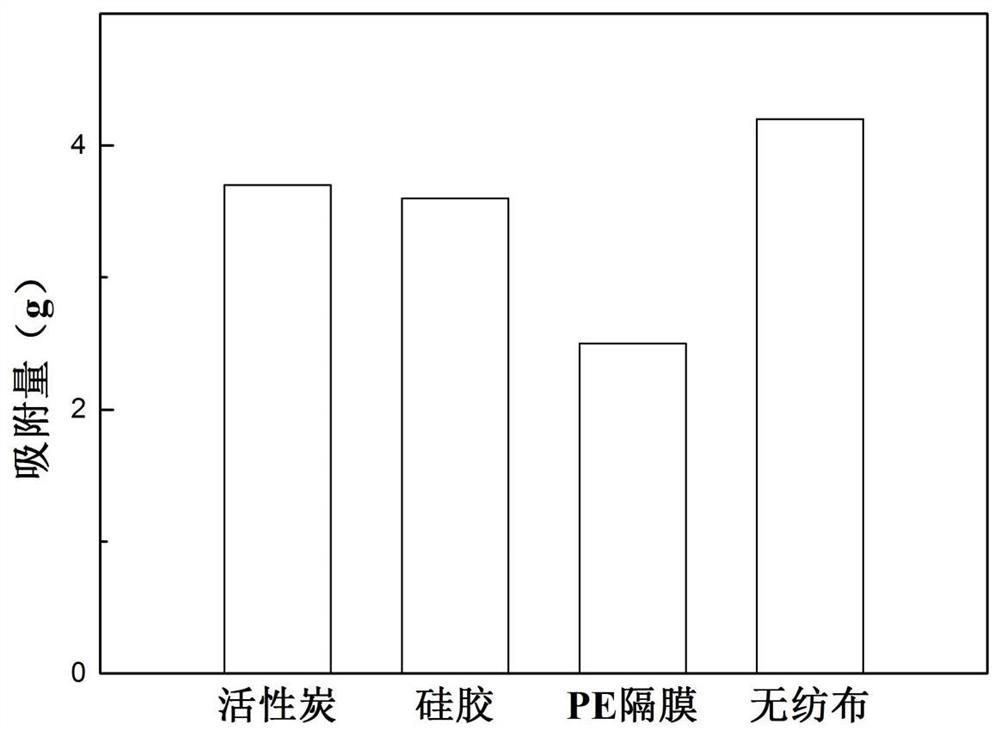

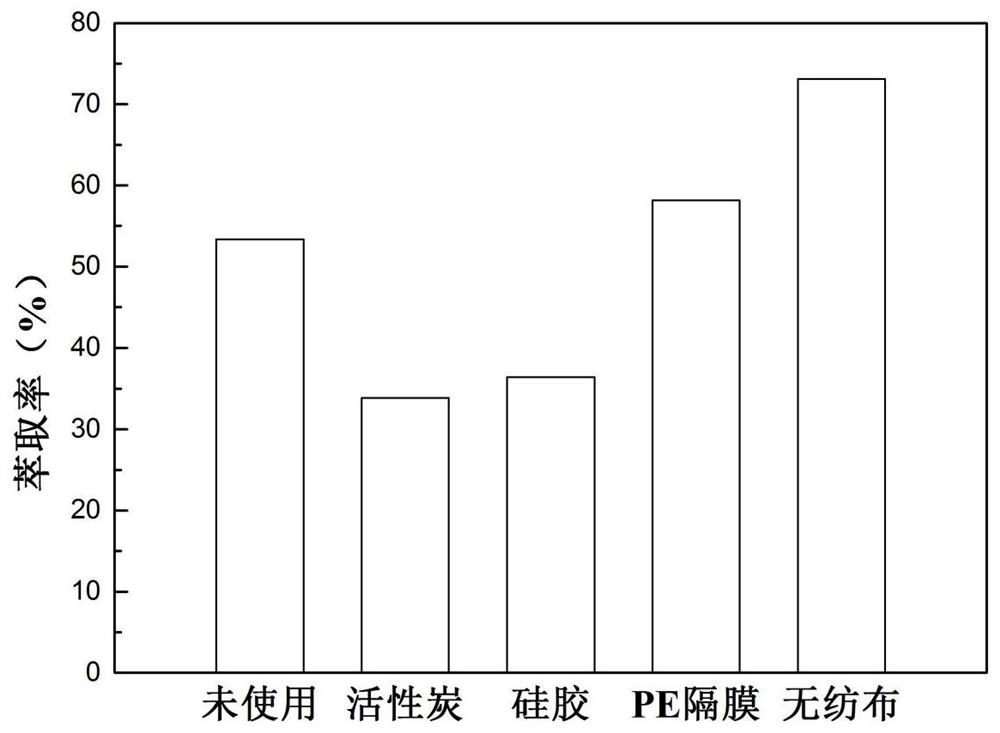

Embodiment 1

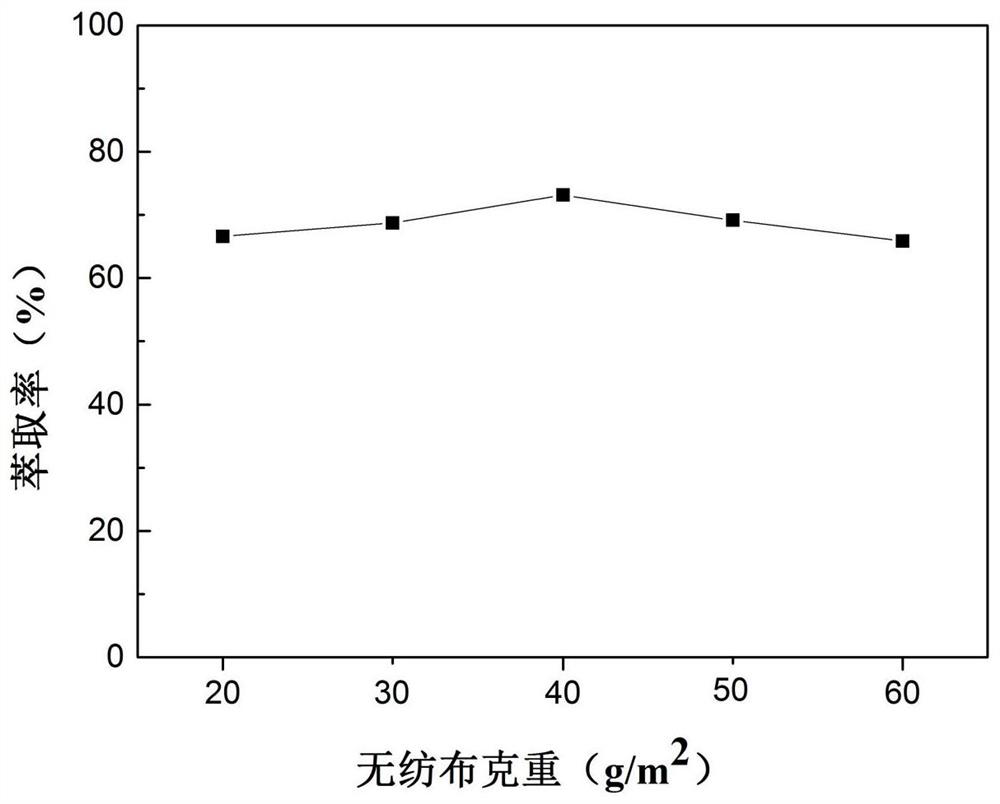

[0049] When the extraction pressure is 24MPa, the extraction temperature is 40°C, and the extraction time is 50min, use 10×12cm 2 PE non-woven fabric is used as the adsorption material, under this condition, the supercritical CO 2 The extraction rate of the fluid to the electrolyte of the spent lithium-ion battery is 73.13%. The extractant is composed of three solvents: DMC, EMC and EC, and does not contain conductive salts.

Embodiment 2

[0051] Compared with Example 1, the difference is that the adsorption material used in Example 2 is 10 × 12cm 2 Non-woven fabric (20g / m 2 ), under this condition, supercritical CO 2 The extraction rate of the fluid to the spent lithium-ion battery electrolyte is 66.58%. The extractant is all composed of DMC, EMC and EC solvents, and does not contain conductive salts.

Embodiment 3

[0053] Compared with Example 1, the difference is that the adsorbent material used in Example 3 is 10 × 12cm 2 Non-woven fabric (30g / m 2 ), under this condition, supercritical CO 2 The extraction rate of the fluid to the electrolyte of the spent lithium-ion battery is 68.72%. The extractant is composed of three solvents: DMC, EMC and EC, and does not contain conductive salts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com