Electrically excited photonic crystal surface emitting type laser element

A photonic crystal and electric excitation technology, which is applied in the direction of electrical components, laser components, lasers, etc., can solve complex technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

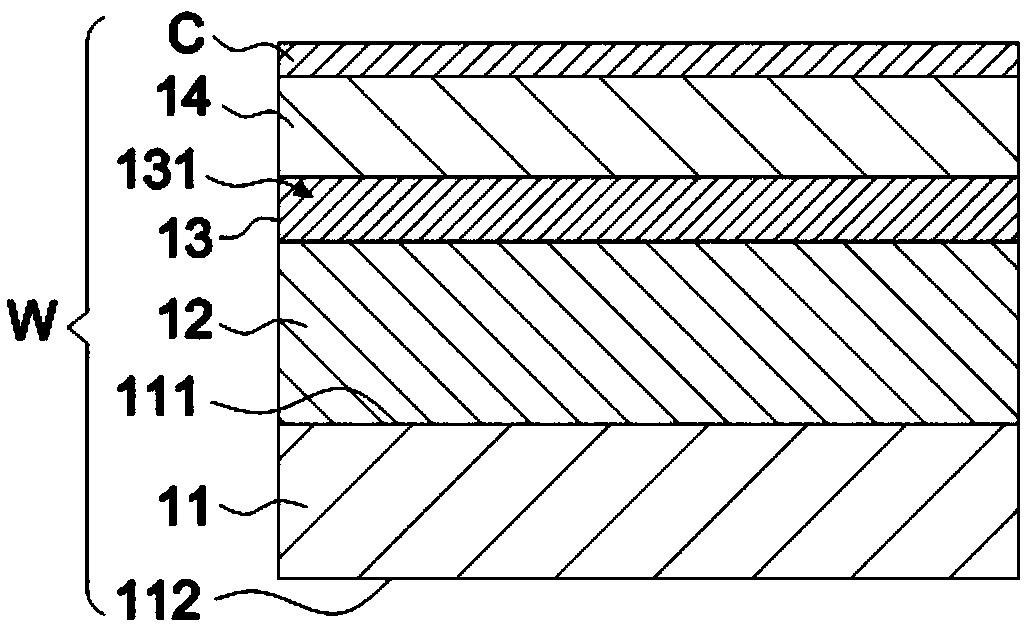

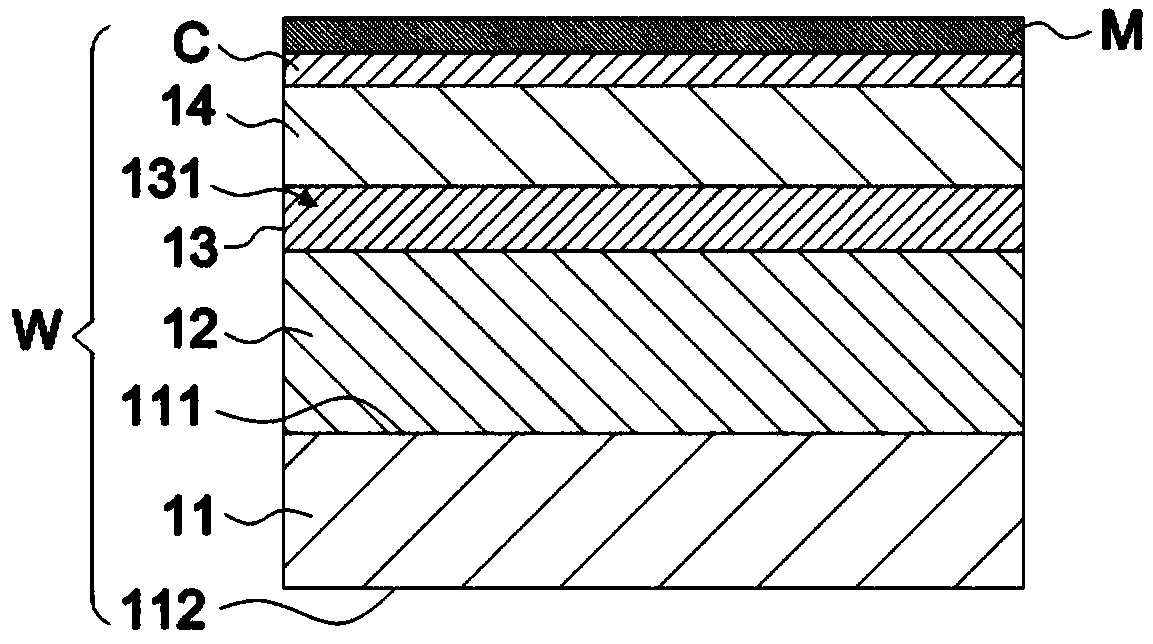

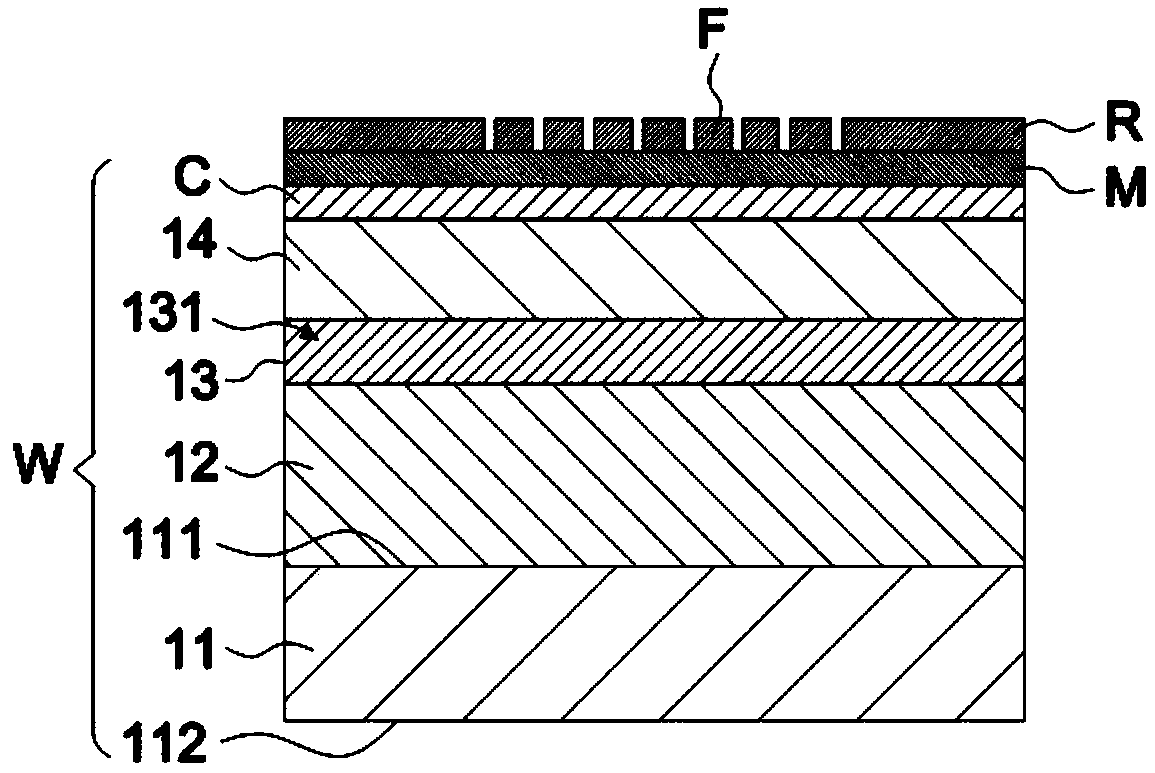

[0083] First, see Figure 1A ~ Figure 1L As shown, a preferred embodiment of an Electrically Pumped Photonic-Crystal Surface-Emitting Laser (Electrically Pumped Photonic-Crystal Surface-Emitting Lasers) component 10A of the present invention includes: a substrate 11 having a first surface 111 and the second surface 112 on the opposite side. In this embodiment, the material of the substrate 11 includes any one of gallium nitride (GaN), gallium arsenide (GaAs), and indium phosphide (InP). Not limited to this.

[0084] A cladding layer (Cladding layer) 12 is located on the first surface 111 of the substrate 11. In this embodiment, the material of the cladding layer 12 includes aluminum gallium arsenide (AlGaAs), gallium arsenide ( GaAs), aluminum gallium nitride (AlGaN), aluminum gallium indium arsenide (AlGaInAs), aluminum gallium indium phosphide (AlGaInP), but not limited thereto.

[0085] An active layer 13 is located on the lower cladding layer 12 and has a quantum structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com