Drill bit for total hip replacement minimally invasive surgery

A technology for total hip replacement and minimally invasive surgery, which is applied in the field of drill bits for minimally invasive surgery for total hip replacement, which can solve the problems of inability to remove, small incision length, damage to the integrity of the joint capsule, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

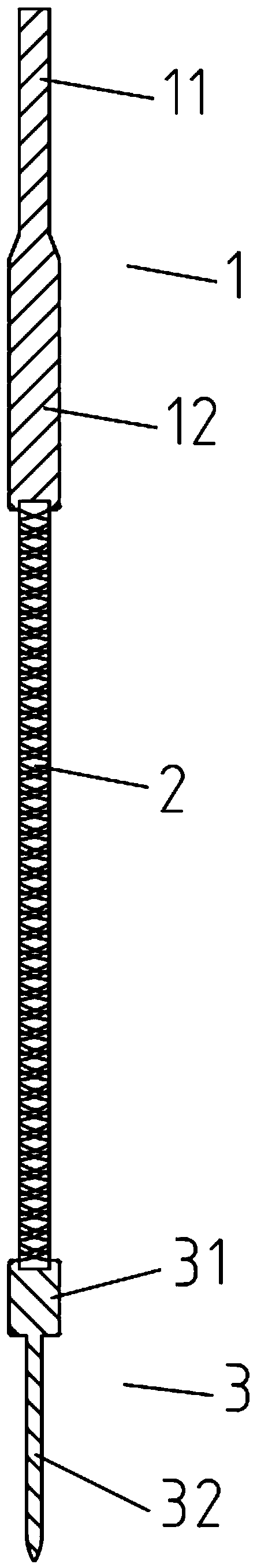

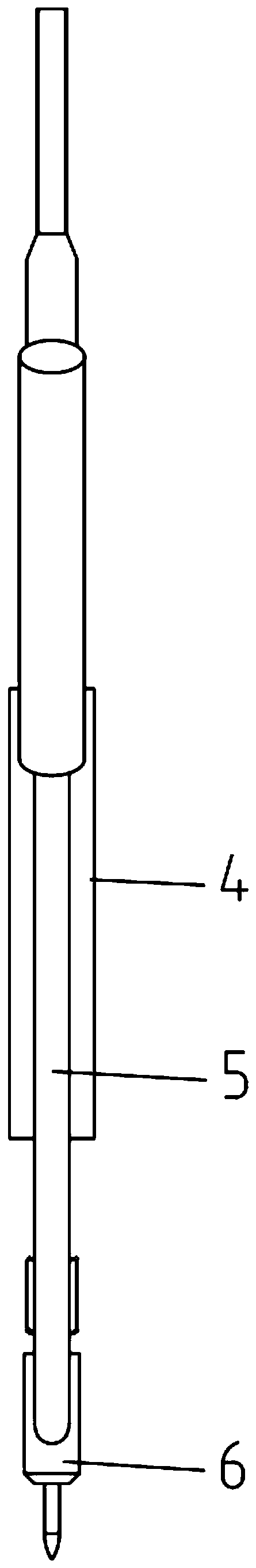

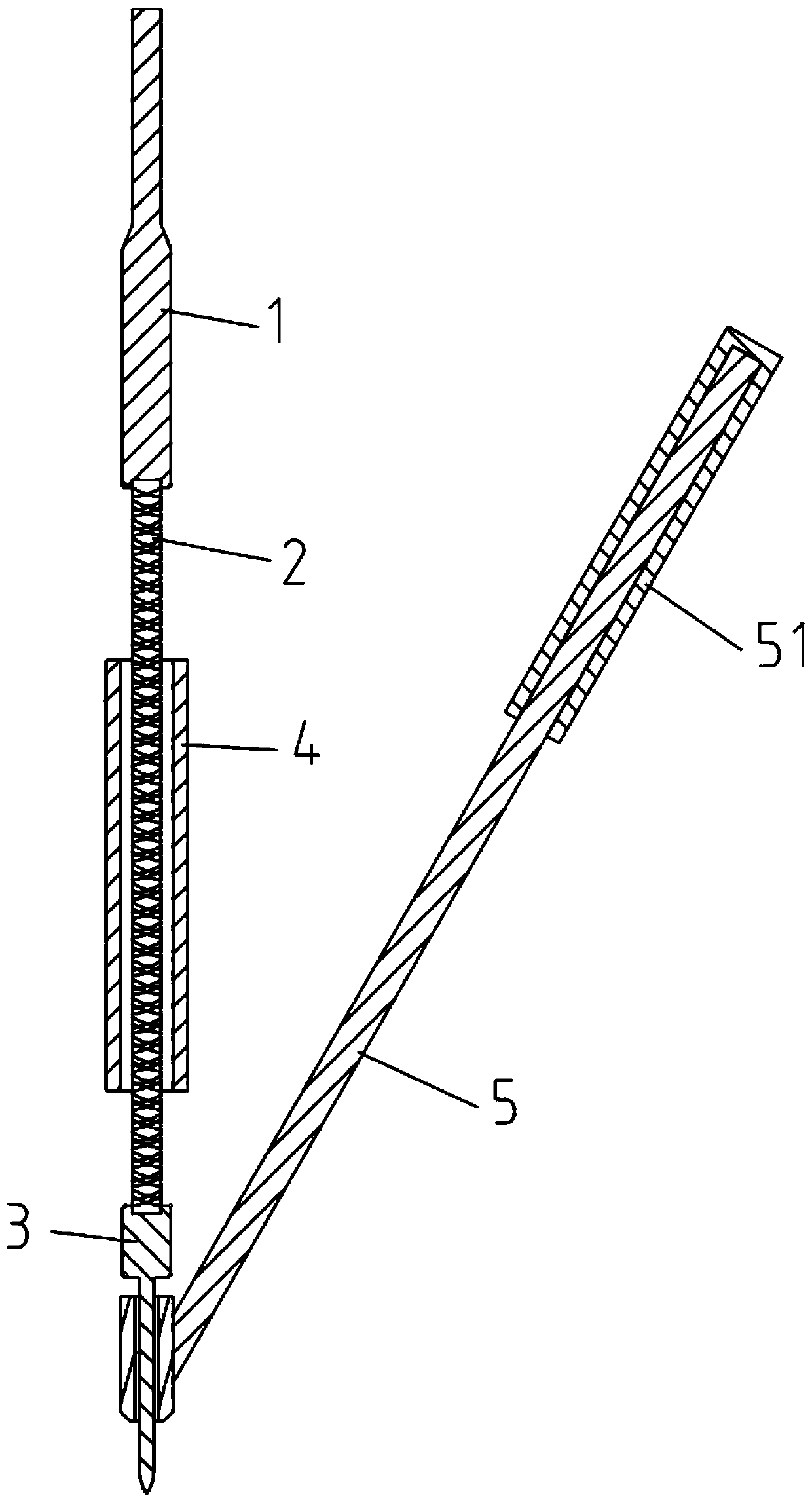

[0015] As shown in the figure, a drill bit for minimally invasive total hip replacement surgery is specially made with a certain degree of flexibility and rigidity to solve how to drill from a small incision along a tortuous path to an accurate position. The problem of implanting acetabular metal parts to fix screws; the specific structure includes a drill body composed of a handle 1, a flexible shaft 2, and a cutting head 3, wherein the flexible shaft 2 is composed of a spring with certain flexibility and rigidity at the same time, and the flexible shaft The two ends of 2 are respectively fixedly connected to the handle 1 and the cutting head 3 by welding. During the operation, the flexible shaft can drive the cutting head to extend to the exact position along the zigzag path, and drive the cutting head to rotate at high speed for drilling.

[0016] The specific structure of the cutting head 3 is composed of a fixed connection section 31 located at the upper section and a cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com