Method for coating surface of wave-absorbing material with magnetic metal film

A technology of magnetic metal and surface coating, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of poor continuity, compactness and uniformity of magnetic metal film, and achieve the process of fine and The steps are easy to operate and the reaction process is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for coating a magnetic metal thin film on the surface of a wave-absorbing material. The coating process is completed through an activation solution, a reduction solution, a plating solution A and a plating solution B.

[0048] Among them, the preparation method of the activation solution is: at normal temperature, weigh 0.25g of palladium chloride, 14g of stannous chloride and 80g of sodium chloride, measure 25mL of concentrated hydrochloric acid and 500mL of deionized water, and then mix palladium chloride, chlorine Add stannous chloride and sodium chloride to concentrated hydrochloric acid and deionized water to dissolve.

[0049] The preparation method of the reducing solution: Dissolve 2-5 g of sodium borohydride in 100 mL of deionized water.

[0050] Prepare 50mL of plating solution A: use 50mL of deionized water to dissolve sodium hypophosphite.

[0051] Prepare 450mL of plating solution B: Dissolve cobalt chloride hexahydrate, sodium citrate, 4-methylbe...

Embodiment 2-4

[0070] For the specific differences between Embodiment 2-4 and Embodiment 1, see Table 1 below. Parts not shown in Table 1 are the same as Embodiment 1. For specific parameters of Embodiment 2-4, see Table 1 below.

[0071] Table 1

[0072]

[0073] in conclusion:

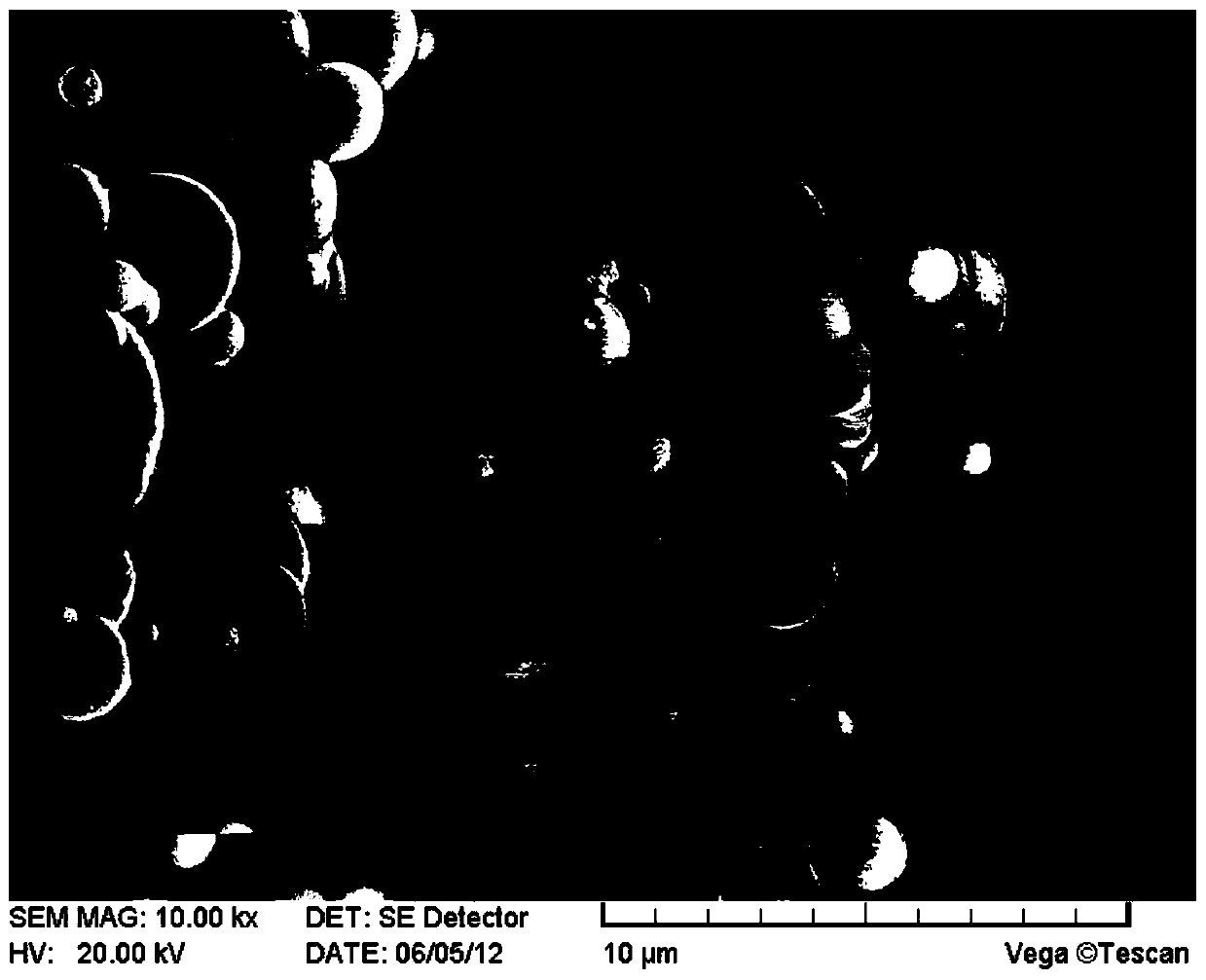

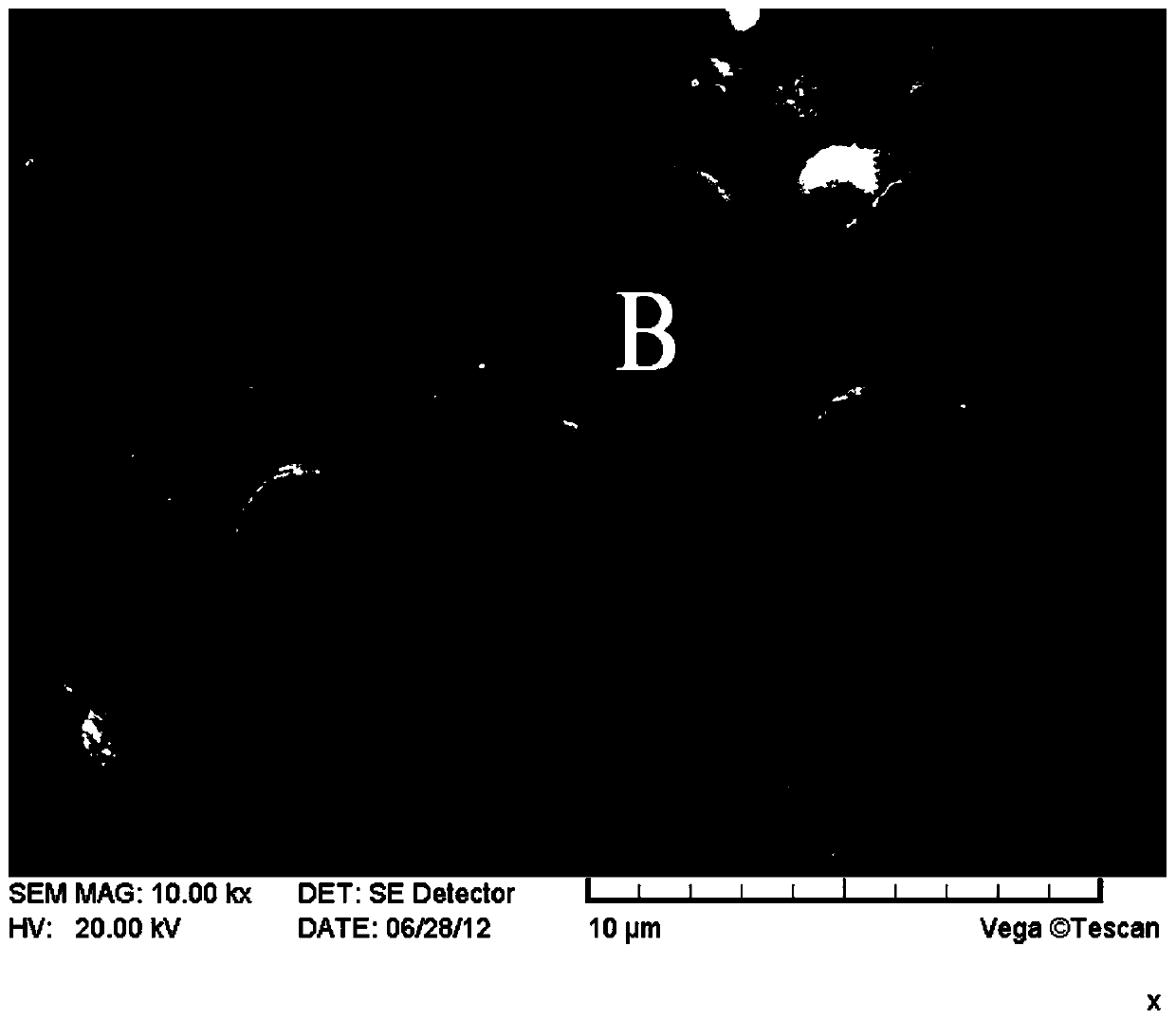

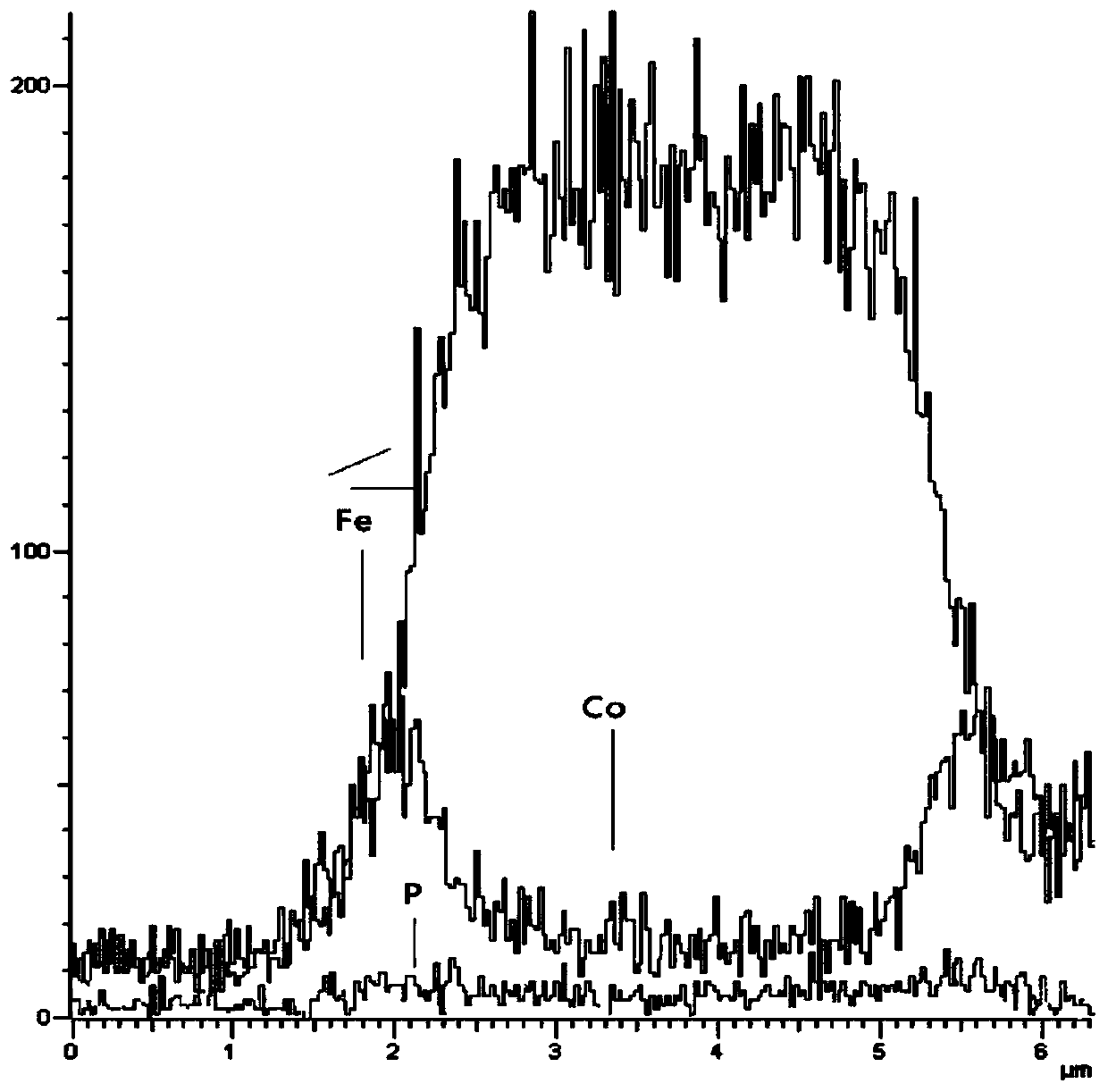

[0074] (1) For Example 1: carbonyl iron powder is one of the most commonly used wave-absorbing materials at present, and its major disadvantage is that it is easy to oxidize. The solution is to coat a layer of magnetic metal film on the surface of carbonyl iron powder to form a Composite absorbing material with core-shell structure. Moreover, since the particle size of the carbonyl iron powder is in the micron level, the specific surface area is large, and it is very easy to agglomerate, the reaction process of coating the magnetic metal cobalt film on the surface of the carbonyl iron powder is very violent, so the coating on the surface of the carbonyl iron powder is continuous, dense and Uniform magnetic met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com