Saline and alkaline land improvement method adopting compound waste

A saline-alkali land and waste technology, which is applied in the field of compound waste to improve saline-alkali land, can solve the problems of waste residue occupying land resources, hidden safety hazards, environmental pollution, etc., and achieve the effects of improving soil fertility, eliminating compaction, and reducing saline-alkali damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

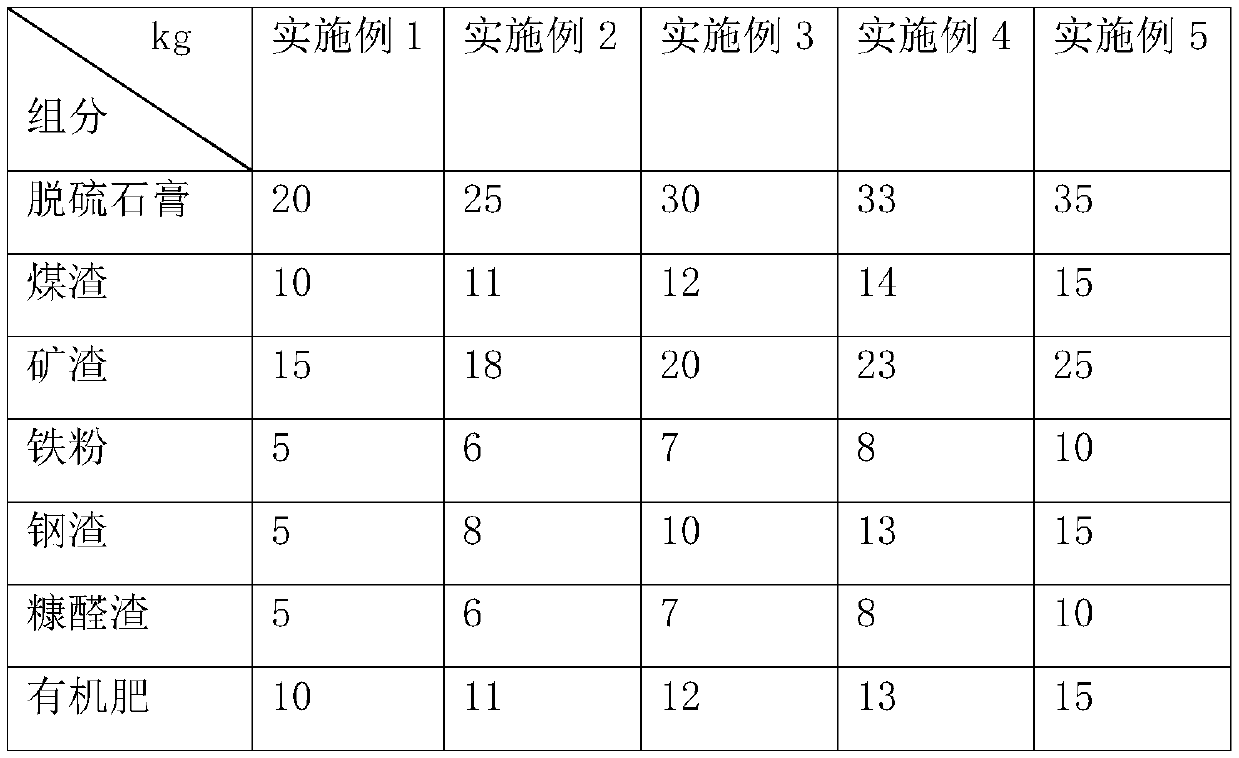

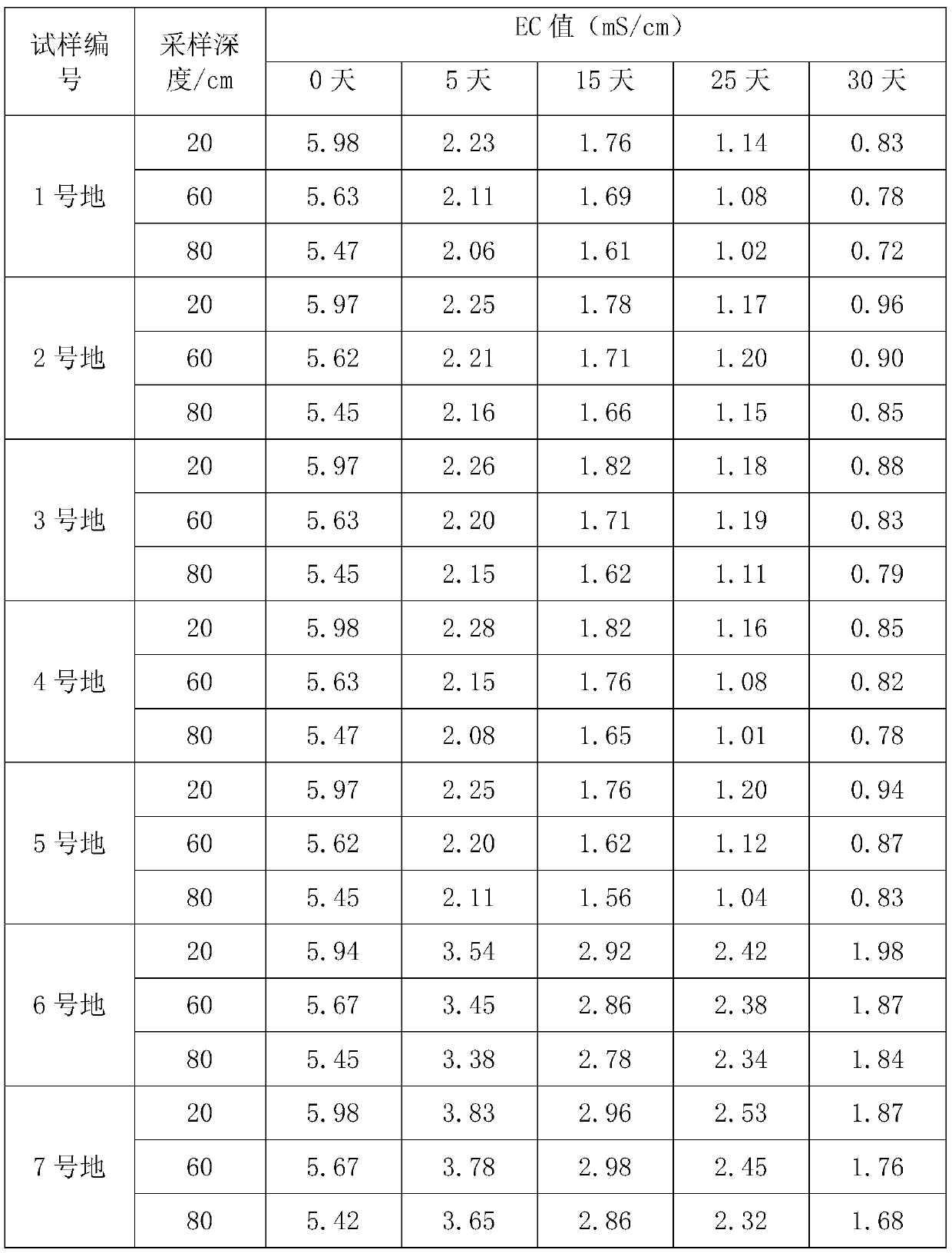

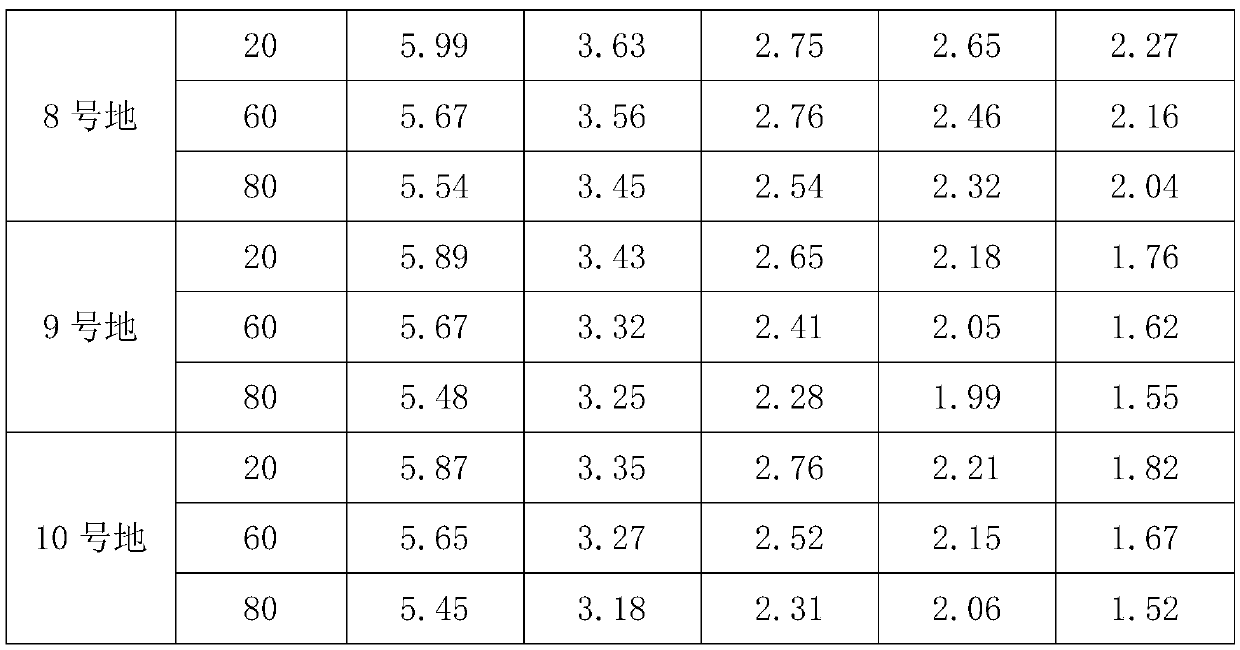

Method used

Image

Examples

preparation example 1-3

[0043] In Preparation Example 1-3, the polyvinyl alcohol is selected from the polyvinyl alcohol sold by Zhengzhou Jinzhifu Trading Co., Ltd. with the brand name of 24-88, and the boron trioxide is selected from the product number KPL8-28934 sold by Shandong Kepler Biotechnology Co., Ltd. The diboron trioxide and steel slag are selected from the steel slag with item number 016 sold by Lingshou County Heshun Mineral Products Processing Plant.

preparation example 1

[0044] Preparation Example 1: Add 1kg of polyvinyl alcohol particles into 3kg of water, stir evenly, and heat up to 50°C; add 0.6kg of boron trioxide to 1.5kg of steel slag, mix well, add to the polyvinyl alcohol solution, and stir well , cured at room temperature, crushed to an average particle size of 20mm.

preparation example 2

[0045] Preparation Example 2: Add 2kg of polyvinyl alcohol particles into 4.5kg of water, stir evenly, and heat up to 60°C; add 0.9kg of boron trioxide to 2.5kg of steel slag, mix well, add to the polyvinyl alcohol solution, and stir Uniform, cured at room temperature, crushed to an average particle size of 30mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com