A kind of preparation method of poly-p-phenylene benzobisoxazole fiber

A technology of benzobisoxazole and polyparaphenylene, applied in the field of material science, can solve the problem of fiber polymerization degree (viscosity does not meet industrialization requirements, 4,6-diaminoresorcinol is unstable, unfavorable polymerization reaction and other problems, to achieve the effect of reducing equipment requirements, reducing polymerization time and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

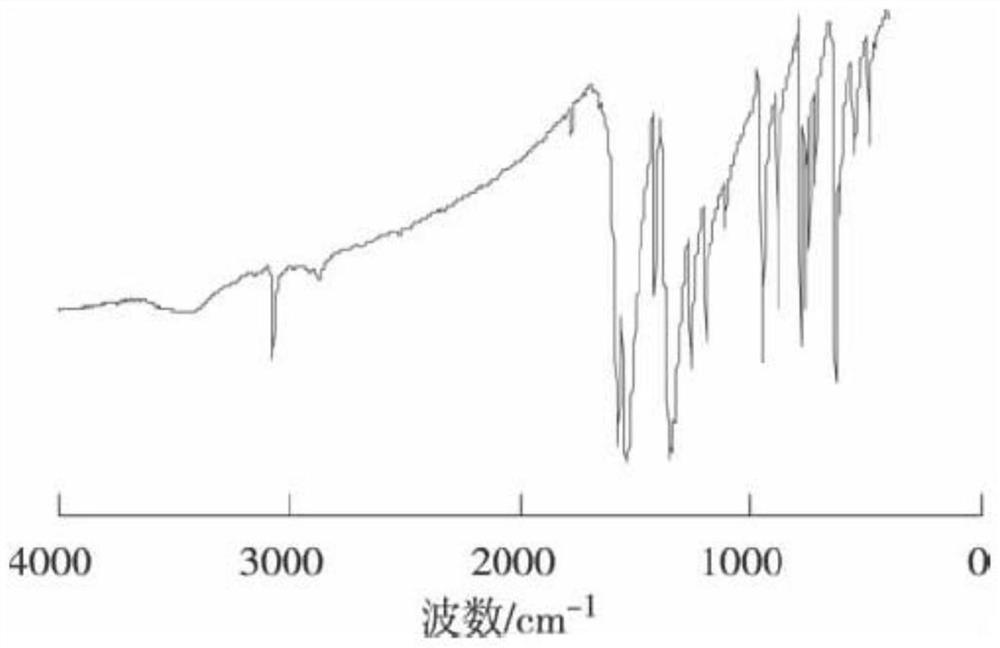

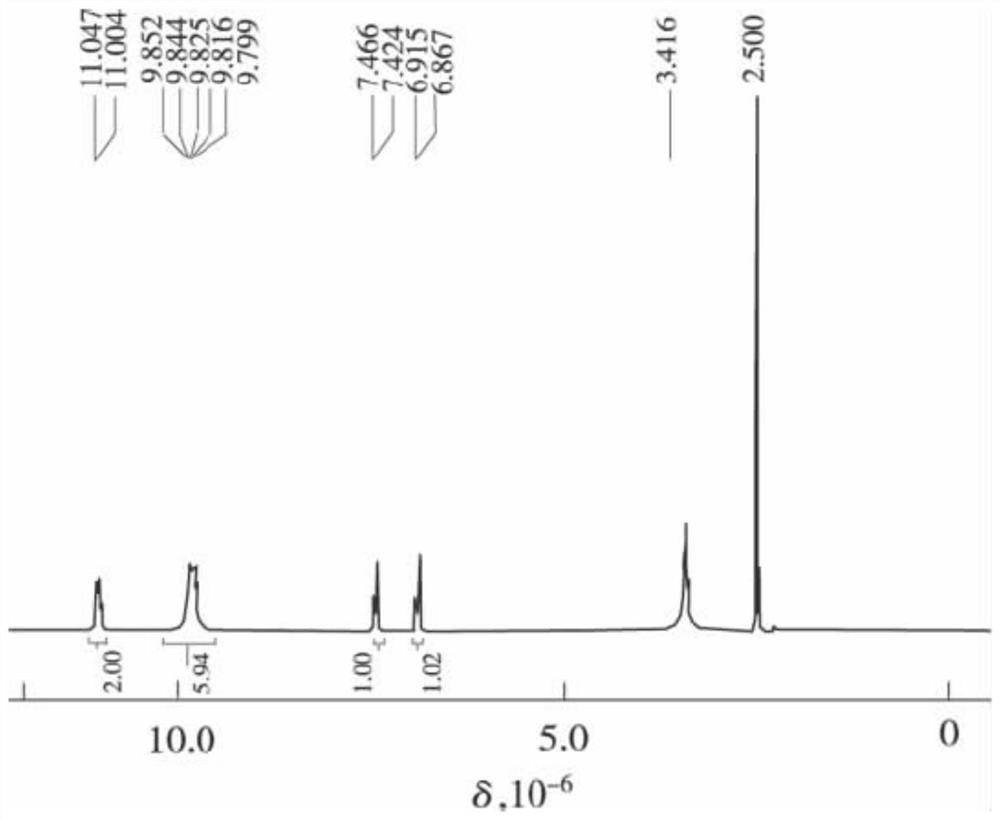

[0040] Add 20g (0.1mol) 4,6-dinitroresorcinol, 200ml methanol and 1.0g 5% palladium carbon (water content is 67.0%) in the autoclave of 500ml, seal the autoclave, nitrogen, hydrogen each replacement 5 Second, slowly raise the temperature to 45°C, pass hydrogen to 0.3MPa, keep it warm for 1.5h under this condition, raise the temperature to 55°C and 0.8MPa, continue to react until the pressure remains constant, continue to keep warm for 0.5h, stop the reaction, and take advantage of the nitrogen protection Heat to filter out the catalyst, add the filtrate dropwise to 20% phosphoric acid aqueous solution, stir fully, cool the filtrate to crystallize, filter to obtain off-white solid, use 0.5% tin protochloride methanol solution to beat the crude product, filter, and vacuum dry to obtain purity >99.5% of 4,6-diaminoresorcinol phosphate, the yield is 85.3%; its IR see attached figure 1 , 1 See attached for H-NMR figure 2 .

[0041] Add 14.0g 84.5% PPA and 8.5g P 2 o 5 , under...

Embodiment 2

[0043] Add 20g (0.1mol) 4,6-dinitroresorcinol, 200g of 4.5% aqueous sodium hydroxide solution and 2.0g Raney / Ni into a 500ml autoclave, seal the reaction vessel, and replace 5 times with nitrogen and hydrogen respectively. Slowly raise the temperature to 45°C, pass hydrogen to 0.3MPa, keep the temperature for 2.5h under this condition, raise the temperature to 55°C and 0.8MPa, continue the reaction until the pressure remains constant, continue to keep the temperature for 0.5h, stop the reaction, and filter while hot under the protection of nitrogen Remove the catalyst, cool the filtrate to 0-5°C, add 0.5g of stannous chloride to the filtrate, add 160g of 20% phosphoric acid dropwise under the protection of nitrogen, a white solid appears during the dropwise addition, and a large amount of solid precipitates after the dropwise, and the crude product is obtained by filtration , the crude product was beaten with 0.5% stannous chloride methanol solution, filtered, and vacuum-dried ...

Embodiment 3

[0046] Add 20g (0.1mol) 4,6-dinitroresorcinol, 180ml methanol and 1.2g 5% palladium carbon (water content is 67.0%) in the autoclave of 500ml, seal the autoclave, nitrogen, hydrogen each replacement 5 Second, slowly raise the temperature to 50°C, pass hydrogen to 0.5MPa, keep it warm for 1.5h under this condition, raise the temperature to 60°C and 1.0MPa, continue to react until the pressure remains constant, continue to keep warm for 0.5h, stop the reaction, and take advantage of the nitrogen protection. Heat to filter out the catalyst, add the filtrate dropwise to 20% phosphoric acid aqueous solution, stir fully, cool the filtrate to crystallize, filter to obtain off-white solid, use 0.5% tin protochloride methanol solution to beat the crude product, filter, and vacuum dry to obtain purity >99.5% of 4,6-diaminoresorcinol phosphate with a yield of 86.4%.

[0047] Add 14.0g of 84.5% PPA and 8.8g of PPA to the reaction flask 2 o 5 , under the protection of nitrogen, start sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com