Modified polypropylene composite material for spraying and preparation method thereof

A technology of composite materials and polypropylene, which is applied in the field of modified polypropylene composite materials for spraying and its preparation, which can solve the problems of not effectively improving the bonding strength, easy peeling of paint, affecting the appearance of exterior decoration parts, and long-term use , to meet the requirements of long-term use, optimize the painting process, and achieve the effect of strong bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

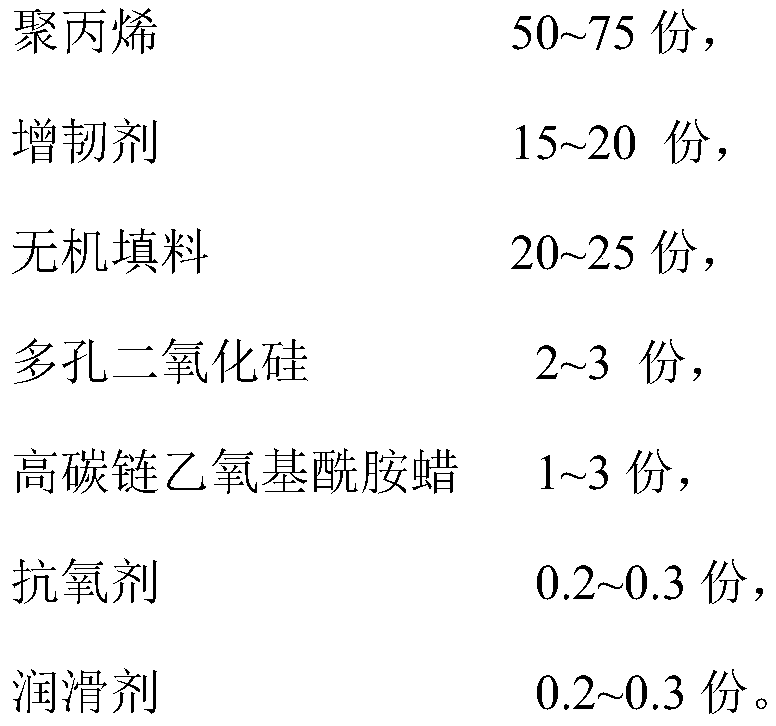

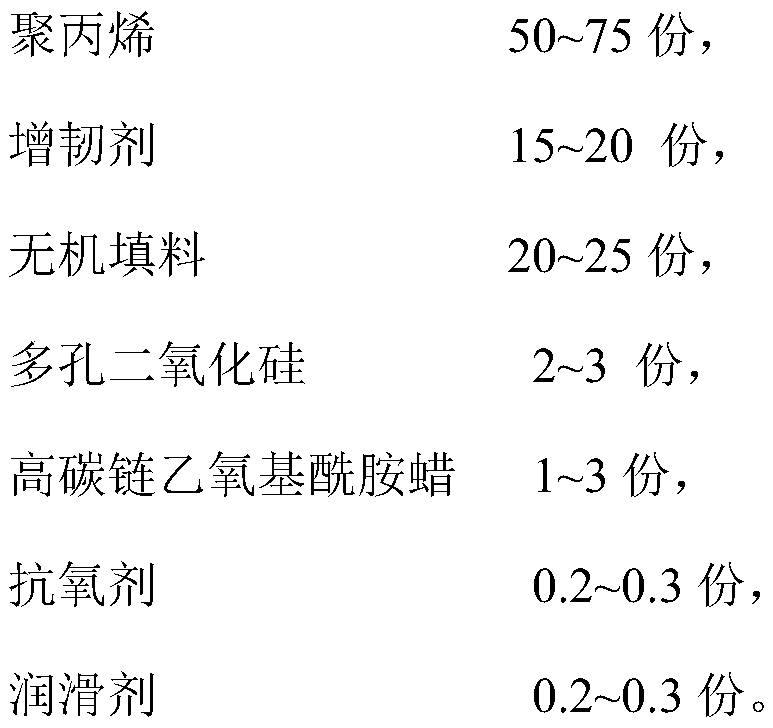

Method used

Image

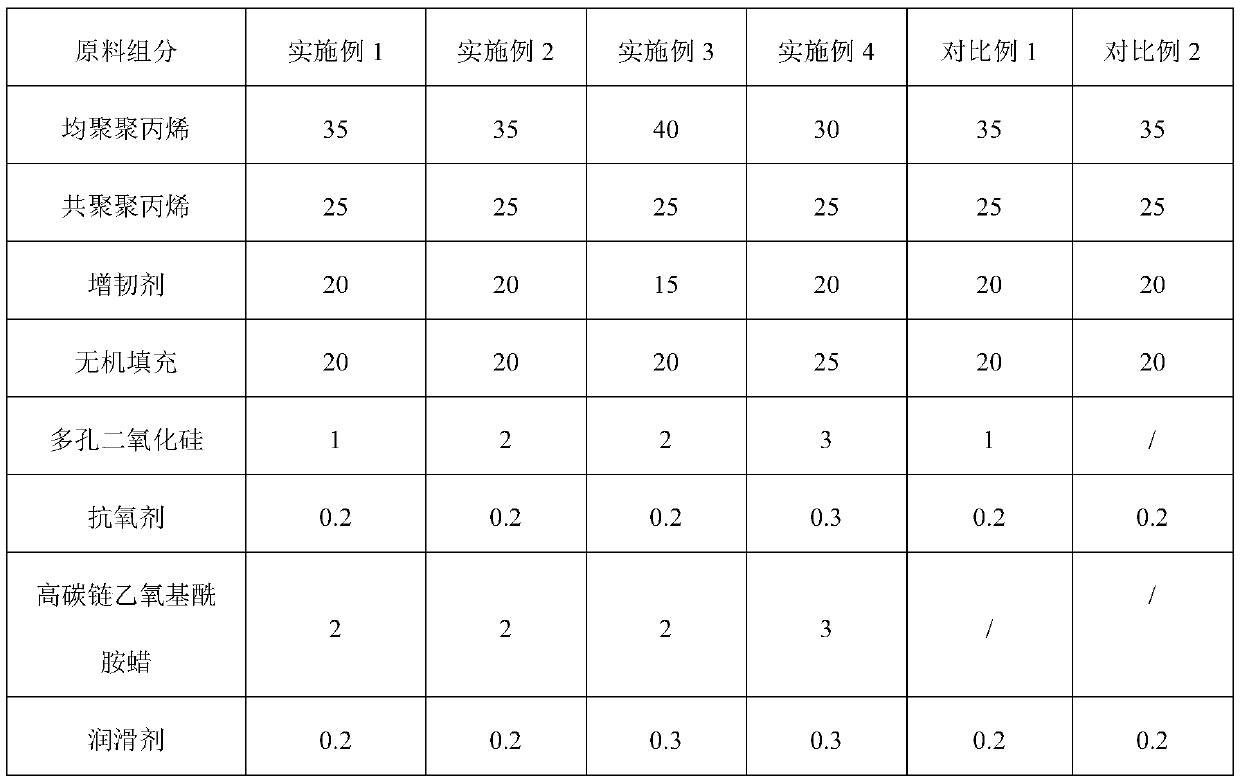

Examples

Embodiment 1

[0027] The preparation method of a modified polypropylene composite material for spraying in this embodiment is as follows:

[0028] (1) Mix polypropylene, toughener, inorganic filler, porous silica, high-carbon chain ethoxyamide wax, antioxidant and lubricant according to the ratio in Table 1 and mix at high speed for 25 minutes. The temperature of the stirring tank is controlled. Stir and mix well at 85°C and then cool to room temperature to obtain a mixture;

[0029] (2) The mixture is put into a twin-screw extruder, melted, extruded, air-dried, and pelletized to obtain a modified polypropylene composite material for spraying, wherein each extruder in the twin-screw extruder described in step (2) The extrusion temperature in the exit zone is 60℃, 70℃, 120℃, 180℃, 200℃, 200℃, 200℃, 200℃, 210℃, 210℃, and the screw speed is 400r / min.

[0030] The inorganic filler used in this embodiment is talc, the toughening agent is ethylene-butene copolymer, the antioxidant is 1076, and the lubr...

Embodiment 2

[0032] The preparation method of a modified polypropylene composite material for spraying in this embodiment is as follows:

[0033] (1) Mix polypropylene, toughener, inorganic filler, porous silica, high-carbon chain ethoxyamide wax, antioxidant and lubricant according to the ratio in Table 1 and mix at high speed for 25 minutes. The temperature of the stirring tank is controlled. Stir and mix well at 85°C and then cool to room temperature to obtain a mixture;

[0034] (2) Put the cooled mixture in 1) into a twin-screw extruder, and obtain a modified polypropylene composite material for spraying after melting, extruding, air-drying, and granulating, wherein the double-screw extruder described in step (2) The extrusion temperature of each extrusion zone in the screw extruder is 55℃, 65℃, 110℃, 170℃, 190℃, 205℃, 205℃, 205℃, 215℃, 215℃, and the screw speed is 420r / min.

[0035] The inorganic filler used in this embodiment is wollastonite, the toughening agent is EPDM, the antioxidan...

Embodiment 3

[0037] The preparation method of a modified polypropylene composite material for spraying in this embodiment is as follows:

[0038] (1) Mix polypropylene, toughener, inorganic filler, porous silica, high-carbon chain ethoxyamide wax, antioxidant and lubricant according to the ratio in Table 1 and mix at high speed for 25 minutes. The temperature of the stirring tank is controlled. Stir and mix well at 85°C and then cool to room temperature to obtain a mixture;

[0039] (2) Put the cooled mixture in 1) into a twin-screw extruder, and obtain a modified polypropylene composite material for spraying after melting, extruding, air-drying, and granulating, wherein the double-screw extruder described in step (2) The extrusion temperature of each extrusion zone in the screw extruder is 65℃, 75℃, 115℃, 175℃, 205℃, 205℃, 210℃, 210℃, 215℃, 215℃, and the screw speed is 450r / min.

[0040] The inorganic filler used in this embodiment is mica, the toughening agent is styrene-butadiene-styrene bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com