Protective film

A technology of protective film and adhesive layer, applied in the direction of film/sheet adhesive, adhesive type, other rubber adhesives, etc., can solve the problem that the haze of the protective film is not low enough, can not suppress debris, Achieves excellent laser processability, suppresses generation of chips, and excellent inspection performance by eliminating problems such as reduced inspection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0252] The adhesive composition (1) obtained in Production Example 2 was applied to the laminate (A) of [substrate layer] / [antistatic layer] obtained in Production Example 4 so that the dried thickness became 75 μm The non-antistatic treated surface was cured and dried at a drying temperature of 130°C and a drying time of 3 minutes. In this way, the adhesive layer (1) formed from the adhesive composition (1) was produced on the base material layer.

[0253] Next, a separator made of a polyester resin with a thickness of 25 μm (trade name “MRF25”, thickness 25 μm, manufactured by Mitsubishi Chemical Corporation) was attached to the surface of the obtained adhesive layer (1). Silicone-treated surface, obtained a protective film (1).

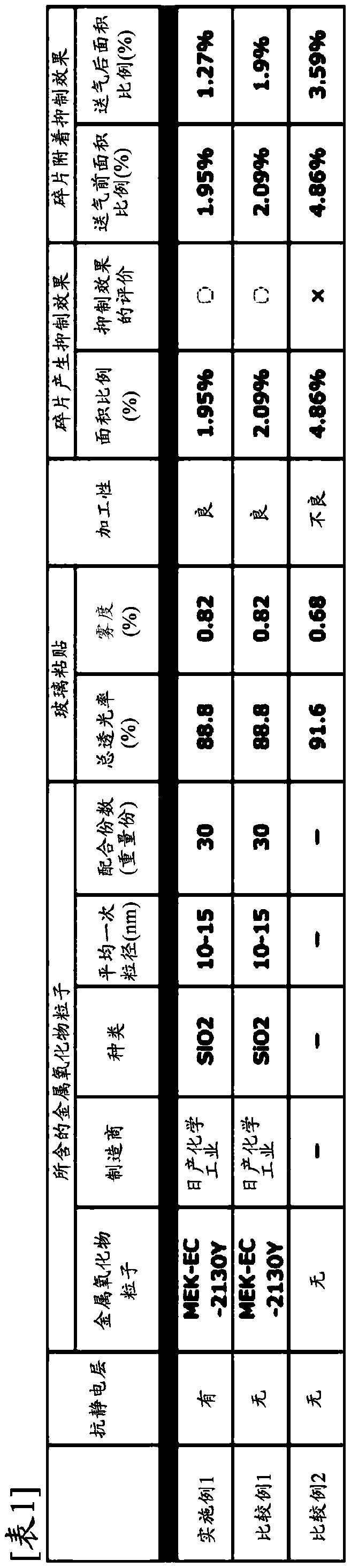

[0254] The obtained protective film (1) was aged at room temperature for 7 days and evaluated. The peeling sheet was peeled off immediately before evaluation. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com