Deep Cement and Sand Rapid Removal System and Method Based on Pneumatic Sand Discharge

A sediment and deep water technology, applied in the field of sediment scouring and silting, can solve problems such as hindering the benefits of water conservancy, water transportation and hydropower projects, and achieve the effect of preventing sediment deposition and preventing sediment siltation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

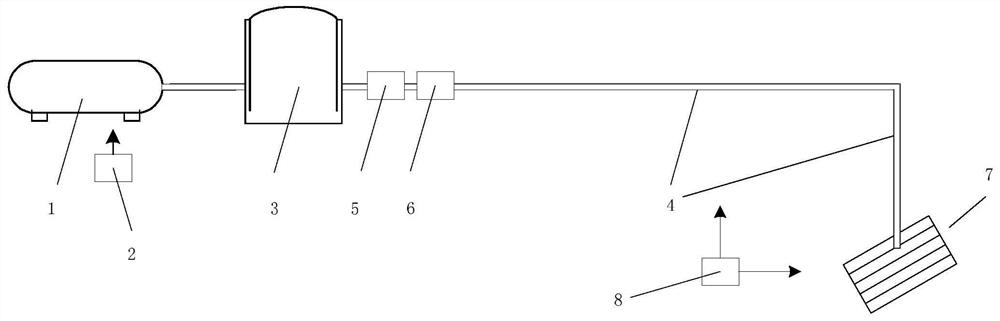

[0032] Example 1, such as figure 1 As shown, the sediment dredging system based on pneumatic sand removal consists of gas generation / air compressor system, gas delivery / pressure pipeline gas delivery system, and gas use / underwater sand removal system.

[0033] The air compressor 1 controls the system 2, obtains the information of the interface equipment 8 of the underwater sand flushing air discharge 7, including the attitude of the sand flushing air discharge 7, GPS positioning, and sediment concentration, compares it with the preset working function of the control system 2, and obtains pressure and flow parameters , the air storage tank 3 is charged. Considering a lot of air compressors is the use of mobile air compressors, which have a wider adaptability to occasions with stricter environmental requirements. At the same time, there is a good match between the air storage tank and the air compressor.

[0034] The air storage tank 3 is inflated to a certain pressure and gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com