Pneumatic disconnection and dust removal device and method for distribution box

A technology of dust removal device and distribution box, which is applied in substation/power distribution device shell, power device inside switch, panel/switch station circuit device, etc., which can solve problems affecting physical and mental health, electric shock, shortening the service life of components, etc. , to avoid the injury of operators and guardians, the operation is completely reliable, and the effect of avoiding physical injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

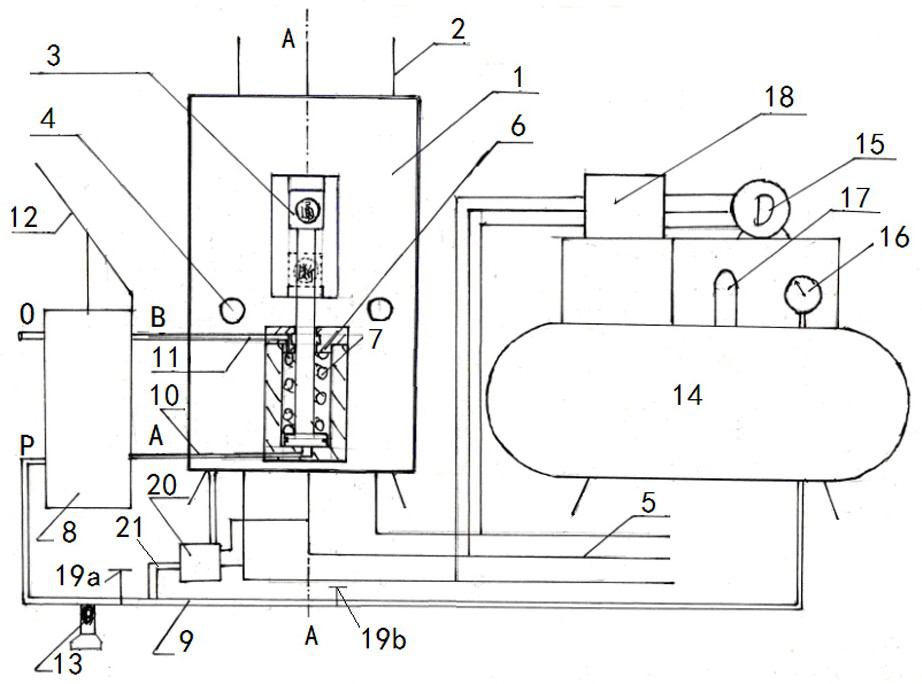

[0041] Embodiment 1, with reference to attached Figure 1-3 , a pneumatic disconnection and dust removal device for a distribution box mentioned in the present invention, its technical solution is: including a distribution box main body 1, a high-voltage household line 2, an electric key 3, an electric key control cylinder 6, and a control reversing air valve 8. Remote air pipeline 9, reversing handle 12, external start-up interface 13, air compressor storage tank 14, air compressor 15, pressure relay 18, first stop valve 19a, second stop valve 19b, solenoid valve 20. Dust removal pipe 21, power terminal 22, power supply terminal 23, electric key fixing plate 24, power contact 25, fixing bolt 26, relay 27, fuse 28, transformer 29, high-voltage household line 2 connected to the distribution box The power terminal 22 in the inner cavity of the main body 1 is fixed on the inner wall of the main body 1 of the distribution box through the electric key fixing plate 24 and the insula...

Embodiment 2

[0057] Embodiment 2, another situation that the present invention runs into is:

[0058] Refer to attached Figure 10 , when the air compressor storage tank 14 or the air compressor 15 fails, the gas manual compression device can be connected through the external starting interface 13, and the gas manual compression device includes a gas exchange joint a, a sealed cylinder liner b, and a sealed piston c , working lead screw d, force nut e, connecting lock cap f, fixing screw g, connecting pin h, locking pin i, transition nut j and hand wheel k, one end of the sealed cylinder b is movably connected to the gas The exchange joint a, the other end is connected to the force nut e through the locking pin i, the center of the gas exchange joint a is provided with a vent nozzle, and is movably connected to the external starting interface 13; the force force nut e There is a working screw d in the center, the outer end of the working screw d is provided with a hand wheel k, the inner ...

Embodiment 3

[0059] Embodiment 3, the difference between the present invention and embodiment 1 is:

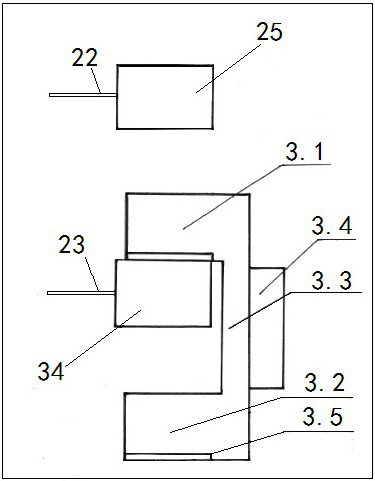

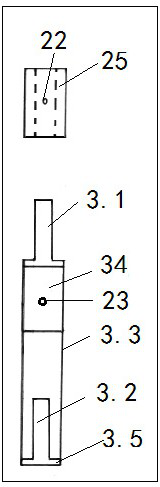

[0060] There is a switch execution block 3.4 on the outside of the bridge connector 3.3 on the side of the electric key. The switch execution block 3.4 is directly connected and fixed with the connecting rod of the electric key control cylinder 6. The electric key control cylinder 6 drives the connection block 35 to move up and down, driving the bridge connector. 3.3 Move up and down, so that the upper contact 3.1 of the electric key and the lower contact 3.2 of the electric key are inserted into the power contact 25 and the power supply contact 34 to form a power circuit, or removed from the power contact 25 and the power supply contact 34 to form a power-off state.

[0061] The switch execution block 3.4 here is provided with a plurality of connecting screw holes 3.6, so that the electric key control cylinder 6 can be installed according to the position of the distribution box, and direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com