Predictive current control method for cascaded H-bridge inverter permanent magnet motor system

A technology for predicting current and permanent magnet motors, which is used in the fields of high-voltage and high-power AC motor variable frequency speed regulation, multi-level inverters and motor drive control. It can solve the problem that the reference voltage vector is no longer accurate, sacrificing system dynamic performance, reducing problems such as the amount of calculation, to achieve the effect of improving the current dynamic characteristics, reducing the amount of calculation, and low common-mode voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

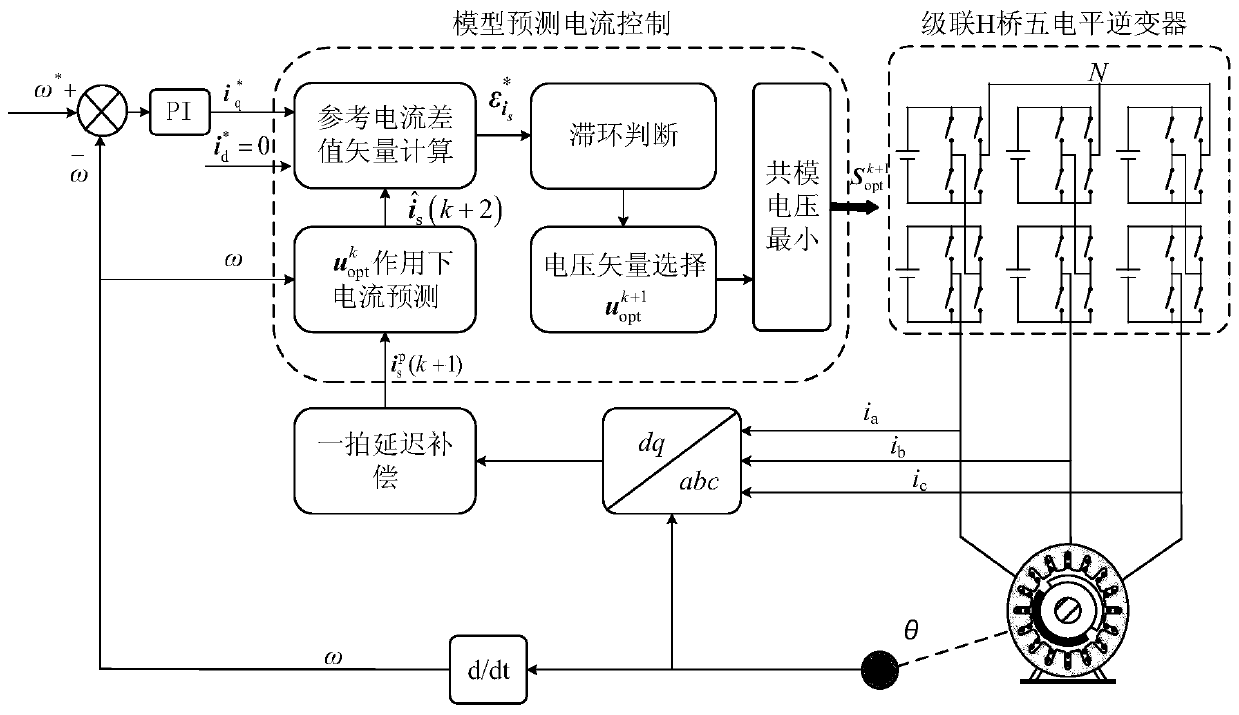

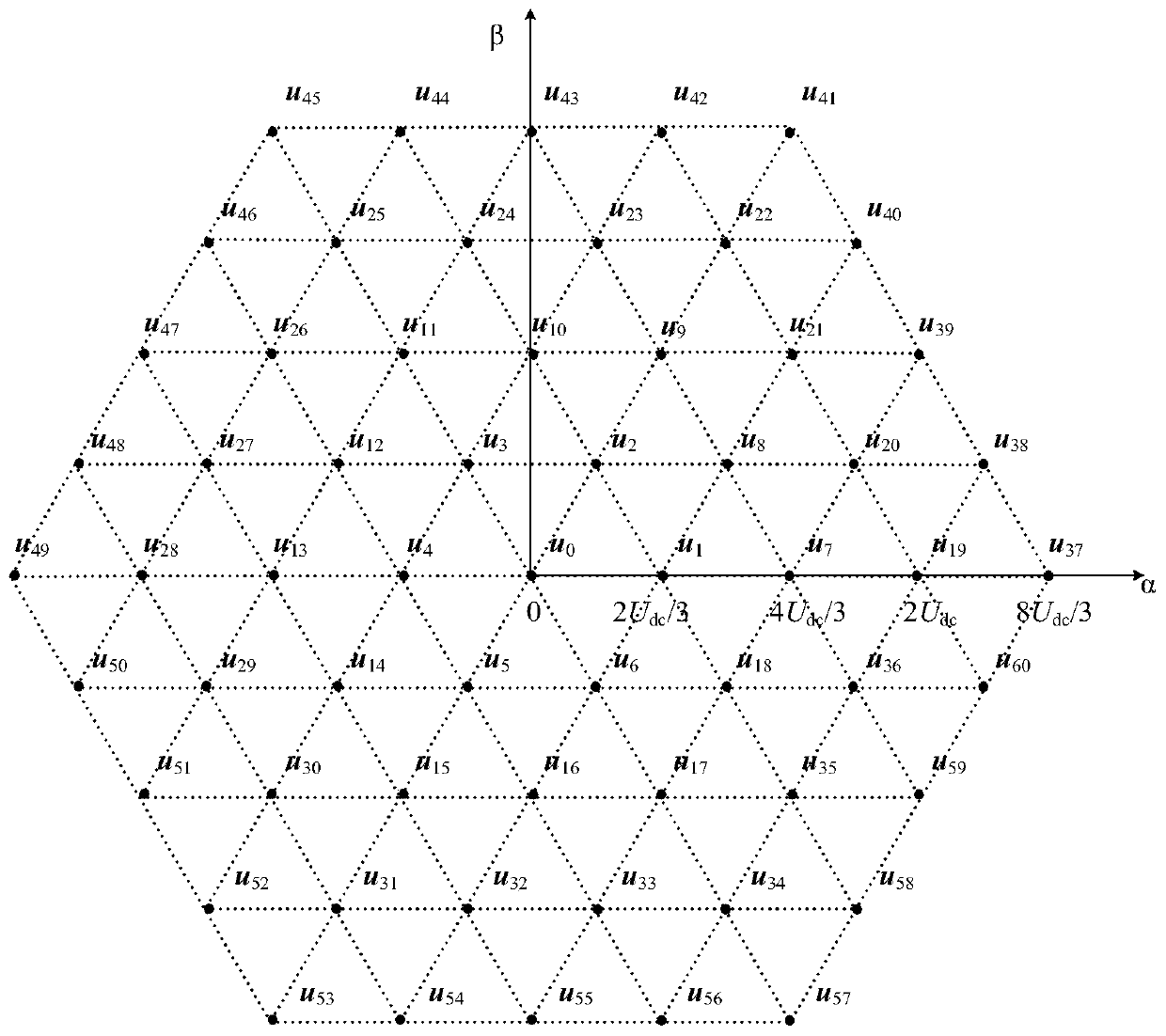

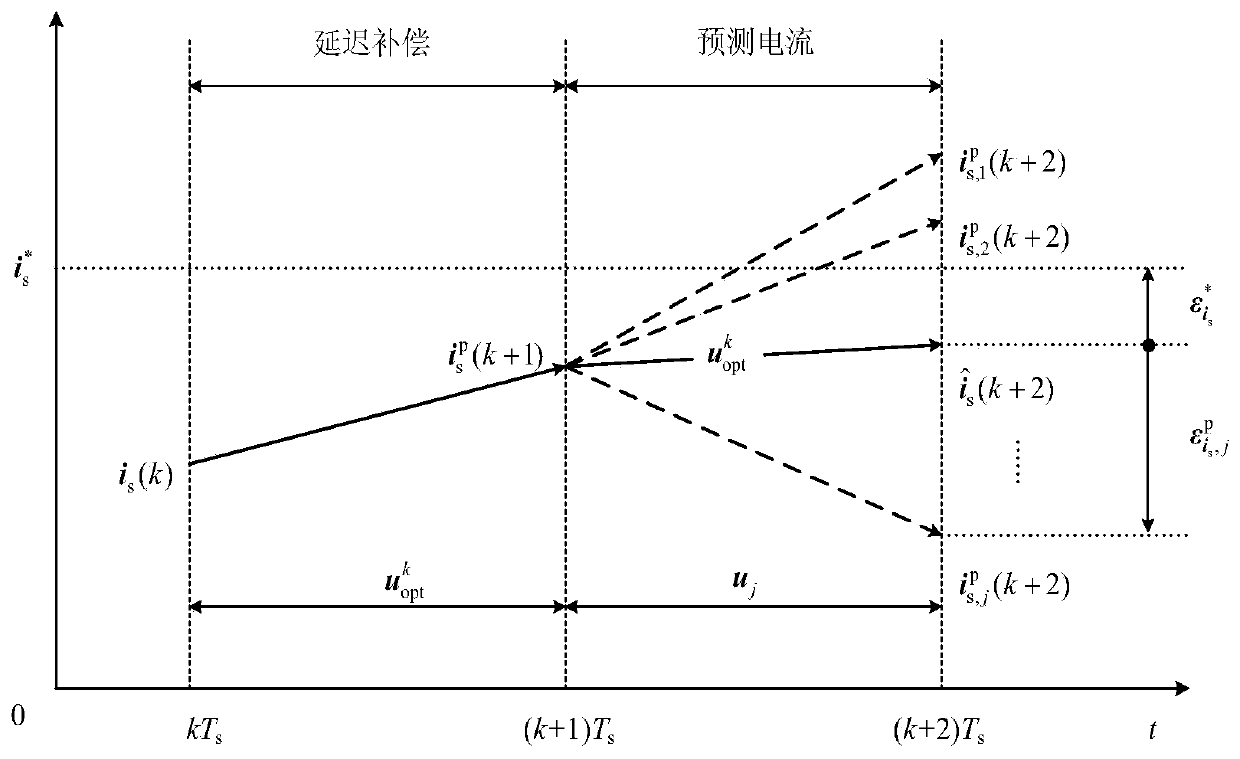

[0038] With the increase of cascaded units, the traditional model predictive control method has problems such as too many voltage space vectors and redundant switch states, complex selection of switch states, and a large amount of calculation. The predicted current trajectory under the continuous action of the vector is calculated to obtain the current error vector; at the same time, the hysteresis control is introduced, and the hysteresis interval is judged according to the magnitude of the current error vector, and the optimal voltage vector is selected according to the phase angle of the current error vector. , so as to determine the optimal voltage vector; in order to reduce the complexity of common-mode voltage and redundant state selection, the optimal voltage vector is gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com