Preparation method of nanosphere-flower-shaped mixed magnesium doped ZnSnO3

A zinc metastannate, mixed-type technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effect of large product volume, large specific surface area, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

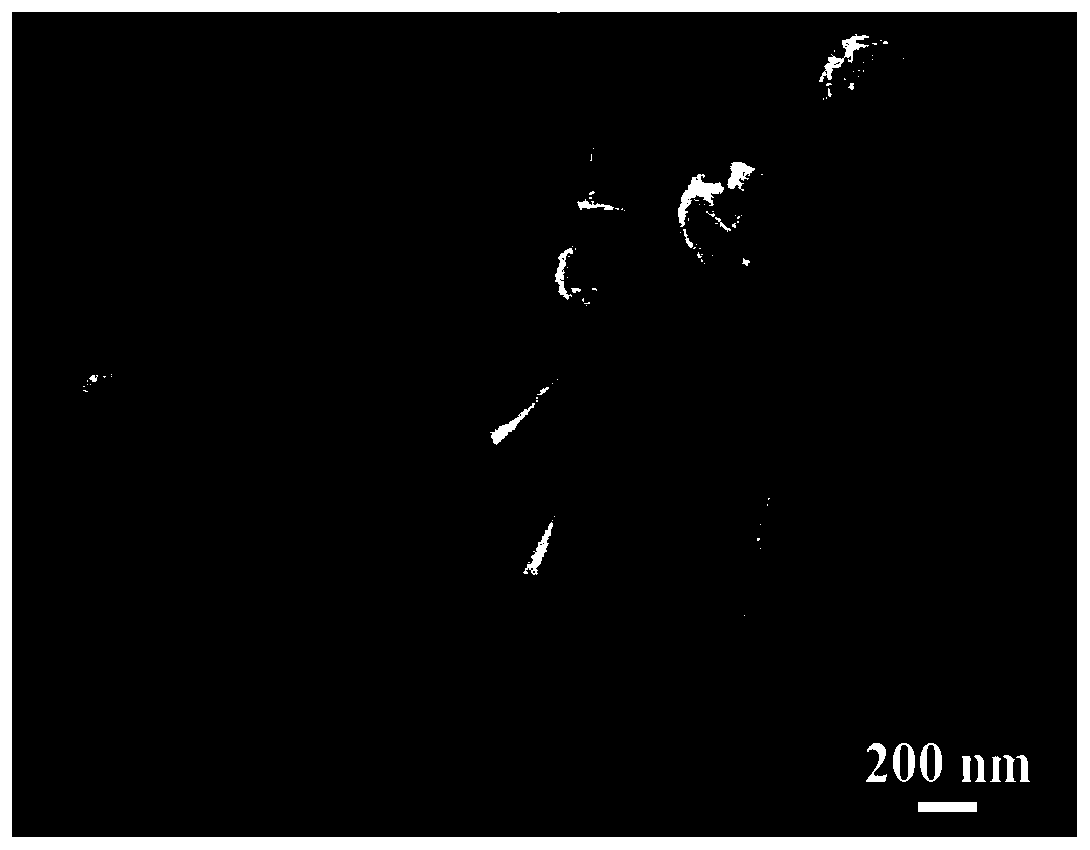

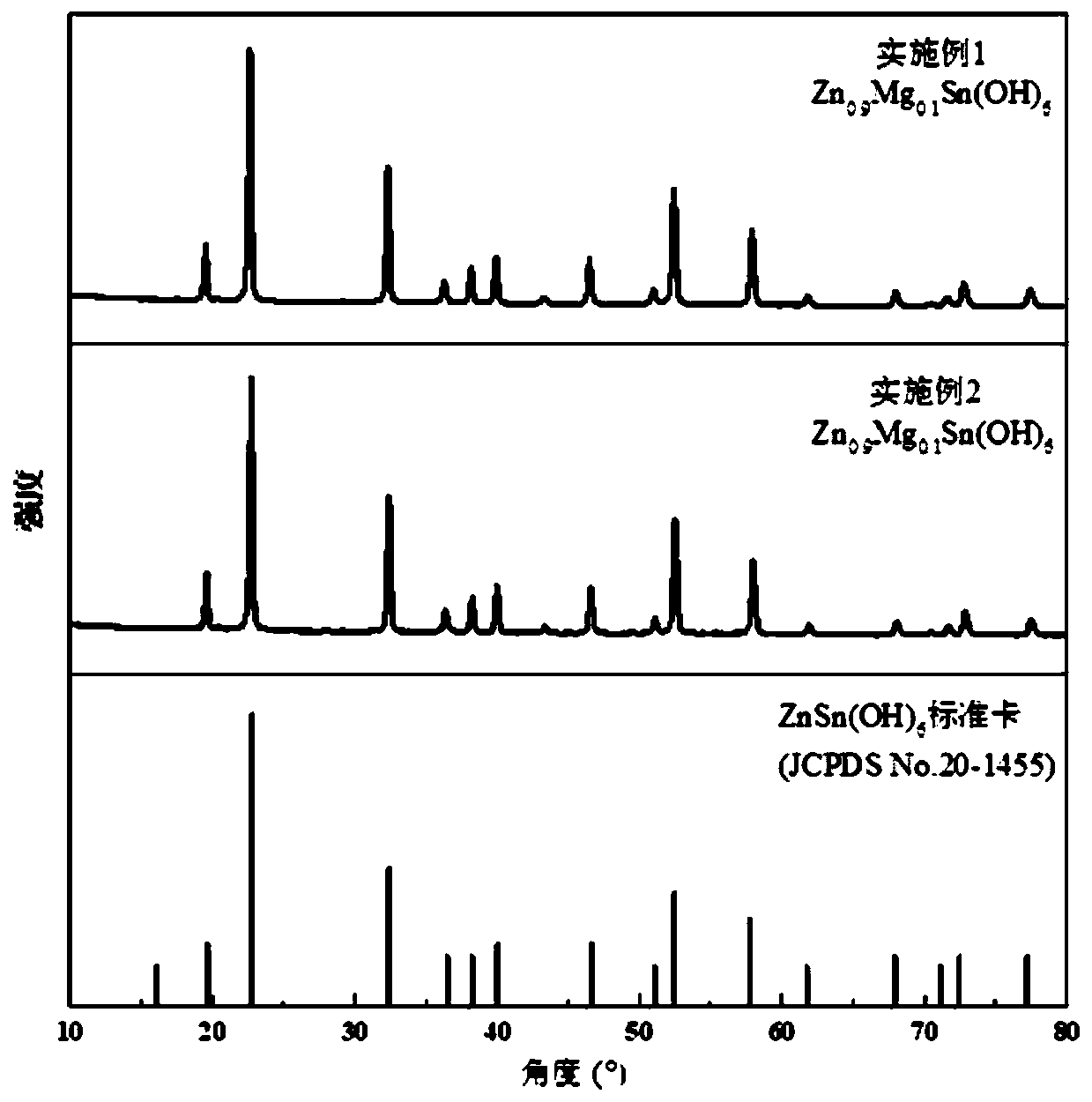

Image

Examples

Embodiment 1

[0022] (1) Weigh SnCl 4 ·5H 2 O was dissolved in absolute ethanol and magnetically stirred for 10 min to prepare SnCl 4 Anhydrous ethanol solution;

[0023] (2) Weigh ZnSO 4 ·7H 2 O and Mg(NO 3 ) 2 ·6H 2 O dissolved in deionized water, the molar ratio of zinc sulfate to magnesium nitrate is ZnSO 4 :Mg(NO 3 ) 2 =9:1, then add triethanolamine (TEOA) dropwise into the solution and stir evenly to form ZnSnO 4 , Mg(NO 3 ) 2 And the mixed solution of TEOA (20wt%);

[0024] (3) Add the solution of step (1) into the solution of step (2), and continue stirring for 15 minutes;

[0025] (4) Prepare a 0.4M NaOH solution, add the NaOH solution dropwise to the mixed solution of step (3) while stirring, the pH value of the solution is 11, continue stirring for 15 minutes after the addition is completed, and then let it stand for 6 hours, Generate unetched precursor precipitation;

[0026] (5) Collect the precipitate obtained from the reaction of step (4), clean it up with deio...

Embodiment 2

[0030] (1) Weigh SnCl 4 ·5H 2 O was dissolved in absolute ethanol and magnetically stirred for 10 min to prepare SnCl 4 Anhydrous ethanol solution;

[0031] (2) Weigh ZnSO 4 ·7H 2 O and Mg(NO 3 ) 2 ·6H 2 O dissolved in deionized water, the molar ratio of zinc sulfate to magnesium nitrate is ZnSO 4 :Mg(NO 3 ) 2 =9:1, drop triethanolamine (TEOA) and stir evenly to form ZnSnO-containing 4 , Mg(NO 3 ) 2 And the mixed solution of TEOA (20wt%);

[0032] (3) Add the solution of step (1) into the solution of step (2), and continue stirring for 15 minutes;

[0033] (4) prepare 0.4M NaOH aqueous solution, under the situation of stirring, add NaOH solution dropwise in the mixed solution of step (3), the pH value of solution is 11, continue to stir for 15min after the dropwise addition is completed, then let stand for 6h, Obtain unetched solid precursor precipitation at this moment; On its basis, the NaOH aqueous solution of 2M is added dropwise while stirring, and the solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com