Fireproof inorganic quartz stone and preparation method thereof

A quartz stone and inorganic technology, applied in the field of refractory inorganic quartz stone and its preparation, can solve the problems of poor fire resistance and low use efficiency, and achieve the effects of improving strength, small shrinkage during drying and firing, and compact body structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

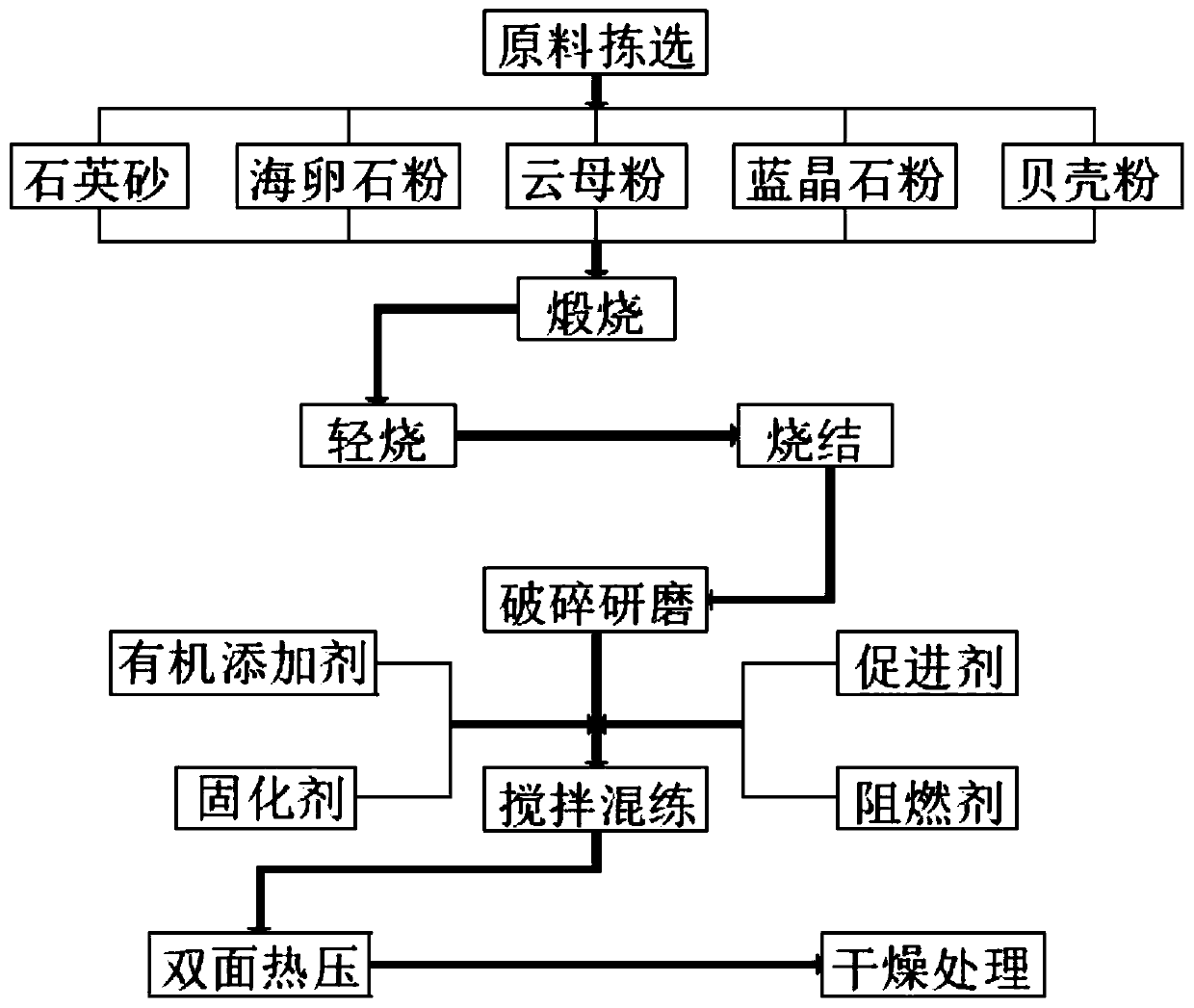

[0024] see figure 1 , the present invention provides a technical solution: a refractory inorganic quartz stone and a preparation method thereof, including a headquarters planning control platform, and the refractory inorganic quartz stone and a preparation method thereof include the following steps:

[0025] S1: first select the raw materials, select 30-50g of quartz sand, 10-20g of sea pebble powder, 1-3g of mica powder, 2-4g of kyanite powder by weight, and 6-8g of shell powder;

[0026] S2: Then, the raw materials selected in S1 are calcined, and the calcining is carried out in two parts, that is, the raw materials are lightly calcined at a reduced temperature, and then the lightly calcined raw materials are finely pulverized to make green bodies or agglomerates , and then sintered at high temperature to make density clinker;

[0027] S3: Followed by crushing the density clinker in S2, grinding the crushed raw materials, and adding grinding aids during the grinding process...

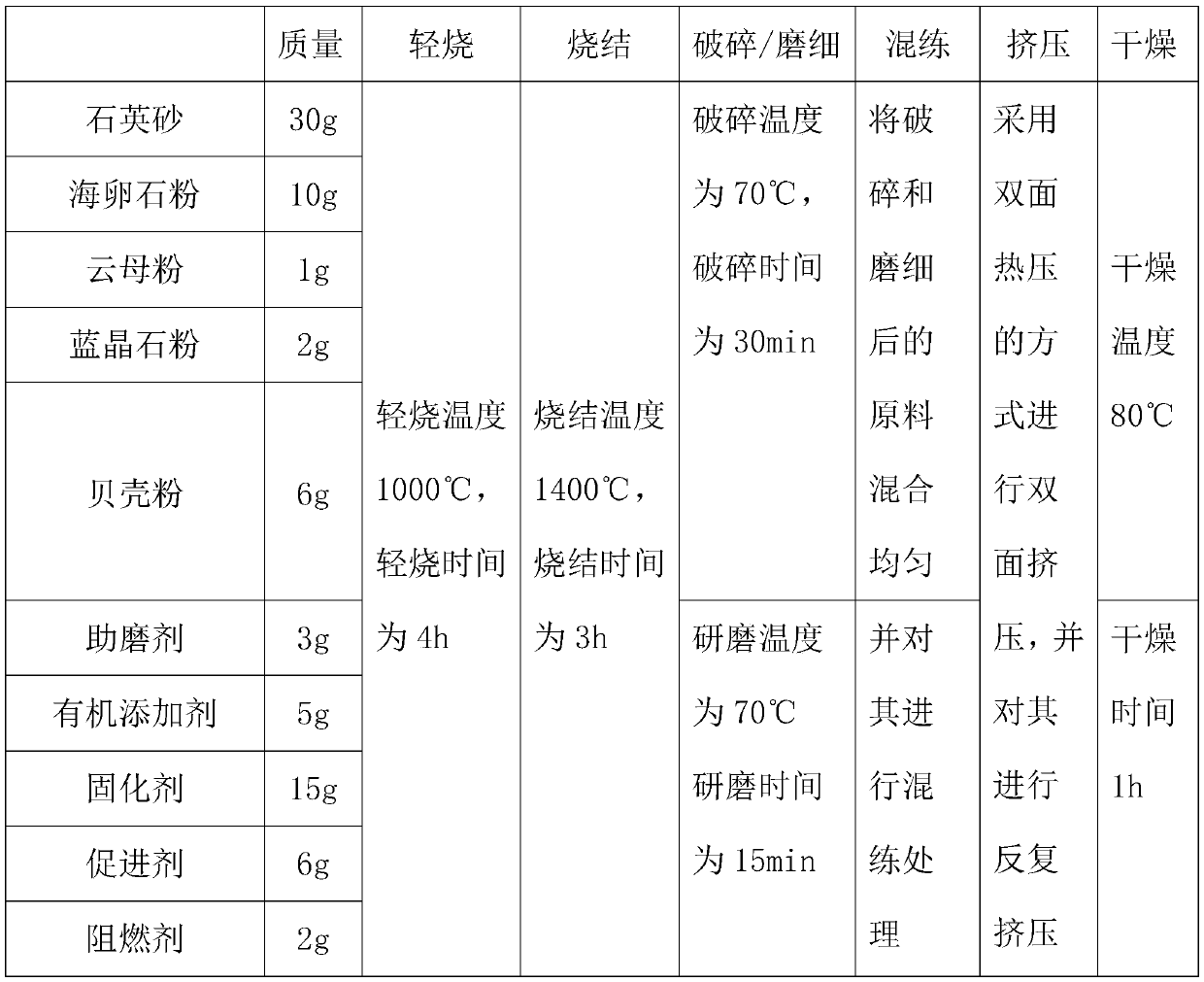

Embodiment 1

[0035] In the present invention, firstly, the raw materials are selected, and 30g of quartz sand, 10g of sea pebble powder, 1g of mica powder, 2g of kyanite powder by weight, and 6g of shell powder are selected, and the selected raw materials are calcined. Partially, that is, the raw materials are first lightly burned at a reduced temperature, and then the lightly burned raw materials are finely pulverized to make embryos or agglomerates, and then sintered at high temperatures to make dense clinker. The density clinker is crushed, and the crushed raw materials are ground, and grinding aids are added during the grinding process to obtain uniform fine raw material particles, and 5g of organic additives and 15g of organic additives are added to the obtained raw materials. Curing agent, 6g of accelerator, 2g of flame retardant, and stir and mix them evenly, and knead them, spread the mixed raw materials evenly on the formwork, and spread them on the four sides of the formwork befor...

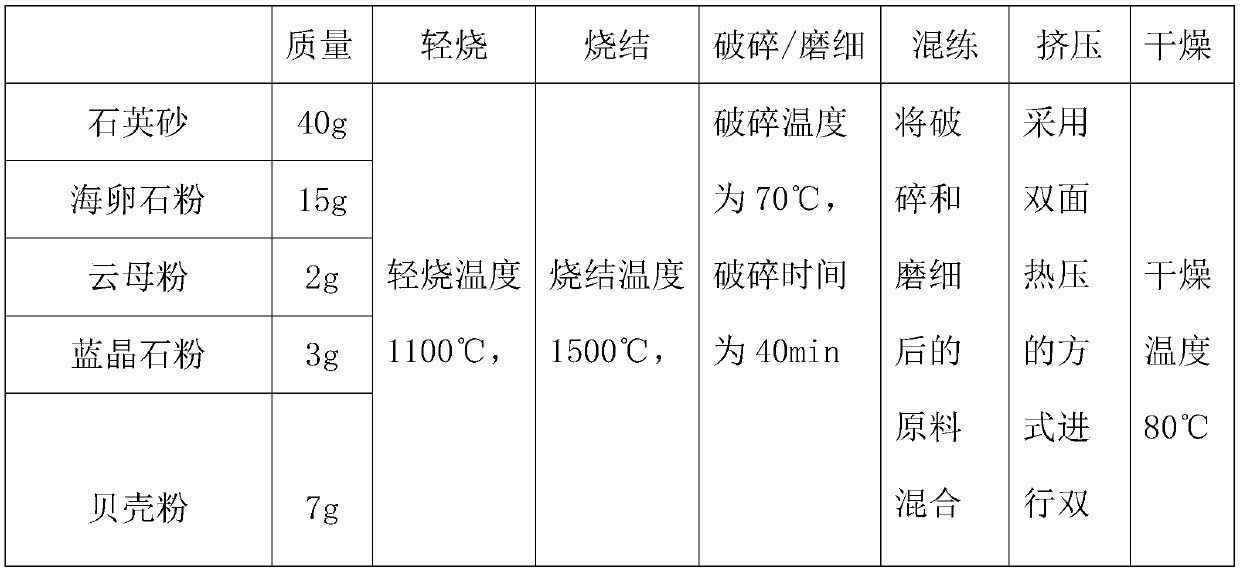

Embodiment 2

[0039] In the present invention, at first the raw materials are sorted, choose 40g of quartz sand, 15g of sea pebble powder, 2g of mica powder, 3g of kyanite powder in parts by weight, and 7g of shell powder, and calcinate the selected raw materials. Partially, that is, the raw materials are first lightly burned at a reduced temperature, and then the lightly burned raw materials are finely pulverized to make embryos or agglomerates, and then sintered at high temperatures to make dense clinker. The density clinker is crushed, and the crushed raw materials are ground, and grinding aids are added during the grinding process, so as to obtain uniform fine raw material particles, and 6g of organic additives, 20g of Curing agent, 7g of accelerator, 3g of flame retardant, and stir and mix them evenly, and knead them, spread the mixed raw materials evenly on the formwork, before laying the raw materials on the four sides of the formwork Apply an appropriate amount of lubricating oil ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com