Preparation method of glass with surface having self-cleaning function film

A self-cleaning, functional technology, applied in the field of photovoltaic cells and electric light sources, can solve problems such as difficult precise control, variance, and high uniformity of performance, and achieve the effects of reducing volatilization loss, high surface activity, and increasing lattice defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The main process equipment is: inorganic salt solution preparation equipment, titanium tetrachloride solution preparation equipment, liquid-liquid dispersion and mixing equipment, roasting and drying equipment, etc. Among them, the liquid-liquid dispersion and mixing equipment is a stirring tank, and the roasting and drying equipment is a muffle furnace.

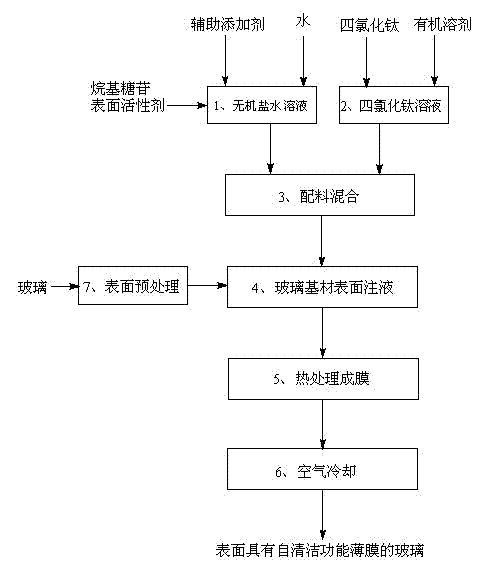

[0055] As shown in the figure, a method for preparing glass with a self-cleaning functional film on the surface, the method steps are as follows:

[0056] (1) Preparation of inorganic salt solution: the auxiliary additive, water and alkyl glycoside surfactant are prepared into an aqueous solution, the alkyl glycoside is octyl glycoside, and the auxiliary additive is indium trichloride InCl 3 . When preparing, 1g of indium trichloride InCl 3 , 2g of alkyl glucoside and 1000mL of hydrochloride-chlorinated water were used to prepare 1000mL of indium trichloride aqueous solution to obtain an inorganic salt solution with ...

Embodiment 2

[0063] The main process equipment is: basically the same as in Embodiment 1, except that the liquid-liquid dispersion and mixing equipment is a ultrasonic emulsifier.

[0064] As shown in the figure, a method for preparing glass with a self-cleaning functional film on the surface, the method steps are as follows:

[0065] (1) Preparation of inorganic salt solution: the auxiliary additive, water and alkyl glycoside surfactant are prepared into an aqueous solution, the alkyl glycoside is decanyl glycoside, and the auxiliary additive is antimony trichloride SbCl 3 . When preparing, 10g antimony trichloride SbCl 3 , 5g of alkyl glucoside and 1000mL of hydrochloride-chlorinated water were used to prepare 1000mL of antimony trichloride aqueous solution, and the mass percentage content of the inorganic salt solution was 1.0% indium trichloride and 0.5% of alkyl glycoside. The glucose polymerization degree DP value of alkylglucose is 2.6;

[0066](2) Titanium tetrachloride solution...

Embodiment 3

[0072] The main process equipment is: basically the same as in Example 1, the difference is that the liquid-liquid dispersion mixing equipment is a static mixer.

[0073] As shown in the figure, a method for preparing glass with a self-cleaning functional film on the surface, the method steps are as follows:

[0074] (1) Preparation of inorganic salt solution: the auxiliary additive, water and alkyl glycoside surfactant are prepared into an aqueous solution, the alkyl glycoside is a combination of dodecyl glycoside and tetradecyl glycoside, and the auxiliary additive is trichloride Indium InCl 3 . When preparing, 5g indium trichloride InCl 3 , 3g of alkyl glucoside and 1000mL of hydrochloride water were used to make 1000mL of indium trichloride aqueous solution, and the mass percentage content of the inorganic salt solution was 0.5% indium trichloride and 0.3% of alkyl glycoside. The glucose polymerization degree DP value of alkylglucose is 2.0;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com