Preparation method of nylon modified thermoplastic silicon phenolic resin

A phenolic resin and thermoplastic technology, which is applied in the field of preparation of modified thermoplastic silicon phenolic resin, can solve the problems of difficult control of reaction, complicated preparation process, poor toughness of new silicon phenolic resin, etc., achieve low price and improve bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

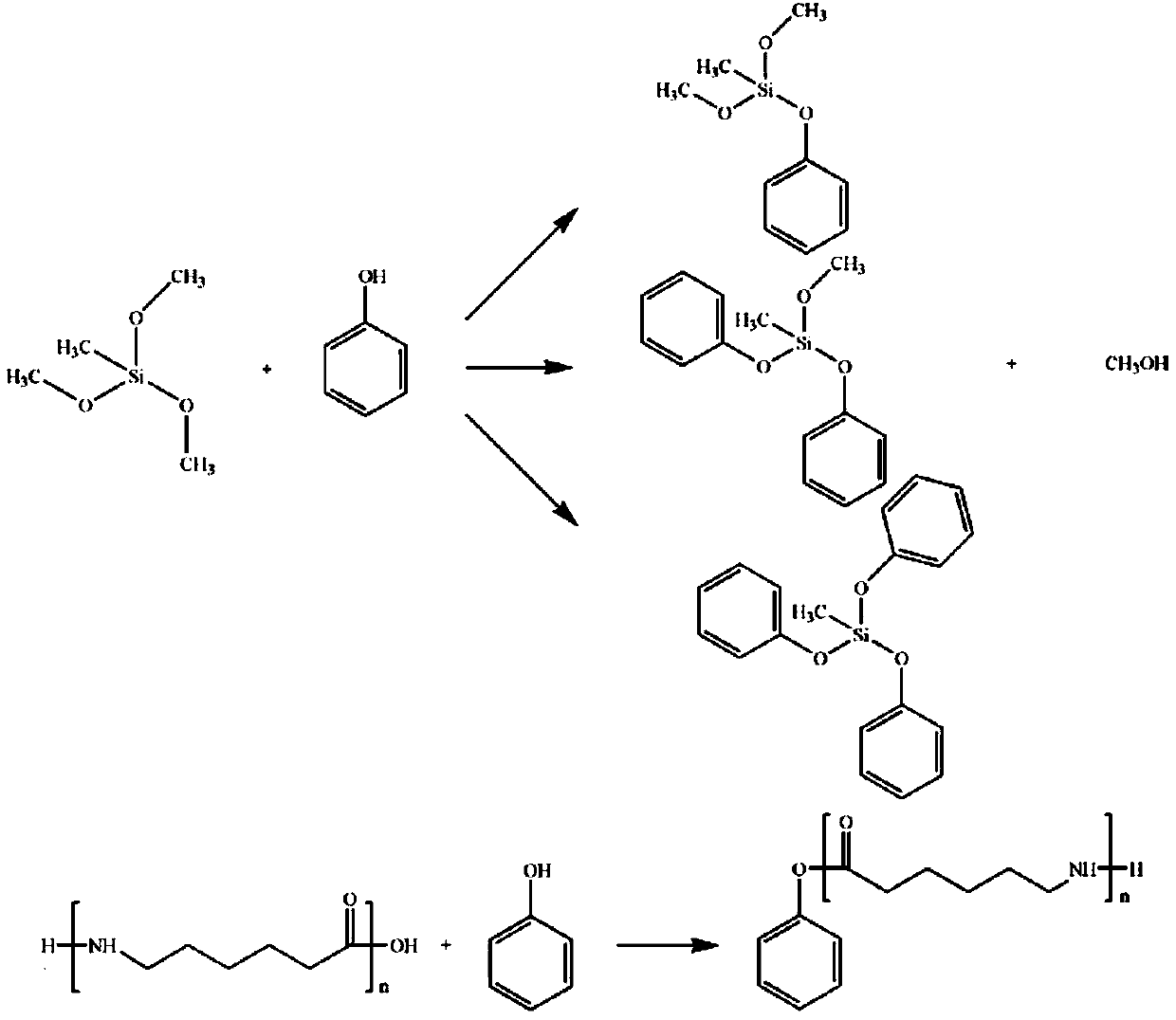

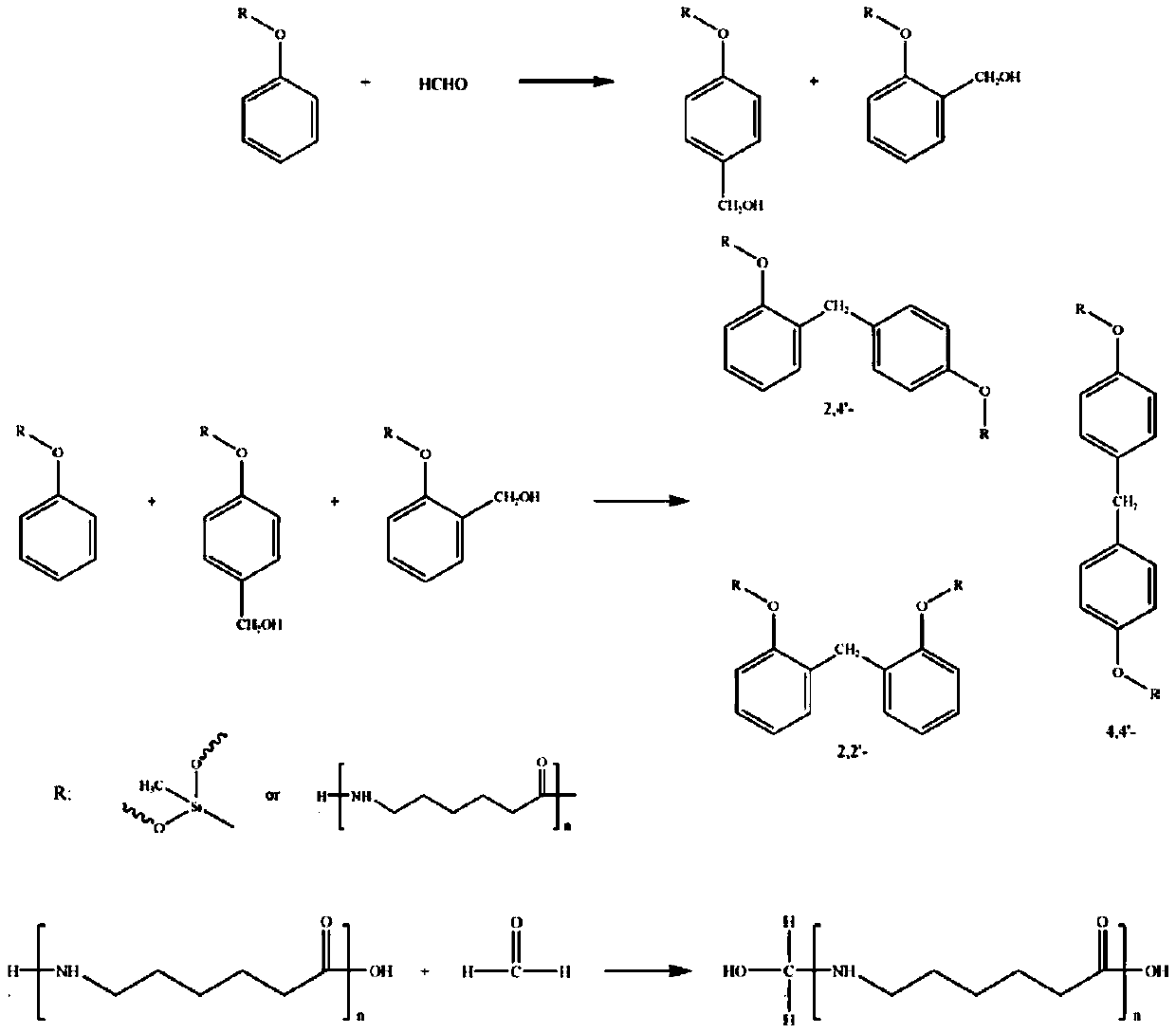

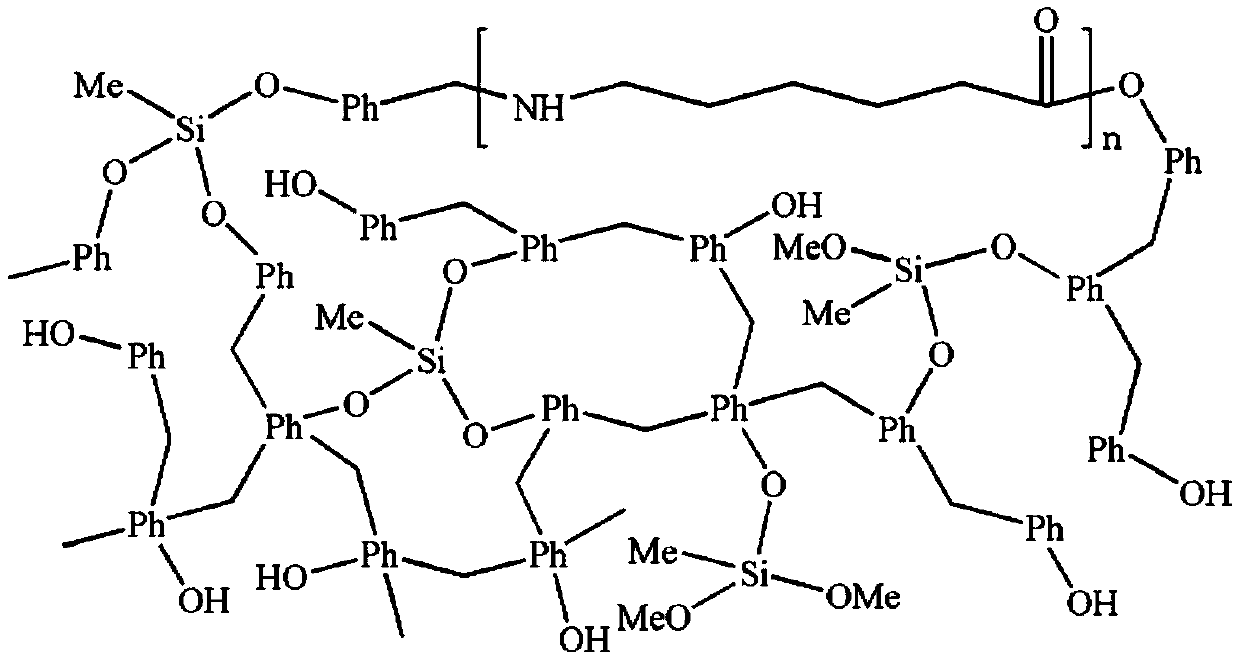

Method used

Image

Examples

Embodiment 1

[0028] Add 22.83g of nylon-1010, 116.20g of methyltrimethoxysilane and 228.29g of bisphenol A into the reaction kettle, stir evenly, add 3.44g of p-toluenesulfonic acid, adjust the pH to about 2, heat up, and react to obtain An intermediate of a silicon atom or an amide group; then cooling down, adding 70.61g of formaldehyde solution, and reacting to the end; drying the product in a vacuum dryer to obtain the nylon-modified thermoplastic silicone phenolic resin.

Embodiment 2

[0030] Add 14.12g of nylon-6, 68.11g of methyltrimethoxysilane and 94.11g of phenol into the reaction kettle, stir evenly, add 1.88g of boric acid, adjust the pH to about 2, heat up, and react to obtain silicon atoms or amide groups Then cool down, add 24.04g of paraformaldehyde, and react to the end; the product is dried in a vacuum dryer to obtain the nylon-modified thermoplastic silicone phenolic resin.

Embodiment 3

[0032] Add 9.41g of nylon-610, 41.27g of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane and 94.11g of phenol into the reaction kettle, stir evenly, add 1.41g of phosphoric acid, Adjust the pH to about 3, heat up, and react to obtain an intermediate containing silicon atoms or amide groups; then cool down, add 26.13g of paraformaldehyde, and react to the end; dry the product in a vacuum dryer to obtain the Nylon modified thermoplastic silicone phenolic resin.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap